A warp knitting machine and a method for access to and control of the machine

A technology of warp knitting machine, control unit, applied in the field of raschel or tricot type warp knitting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

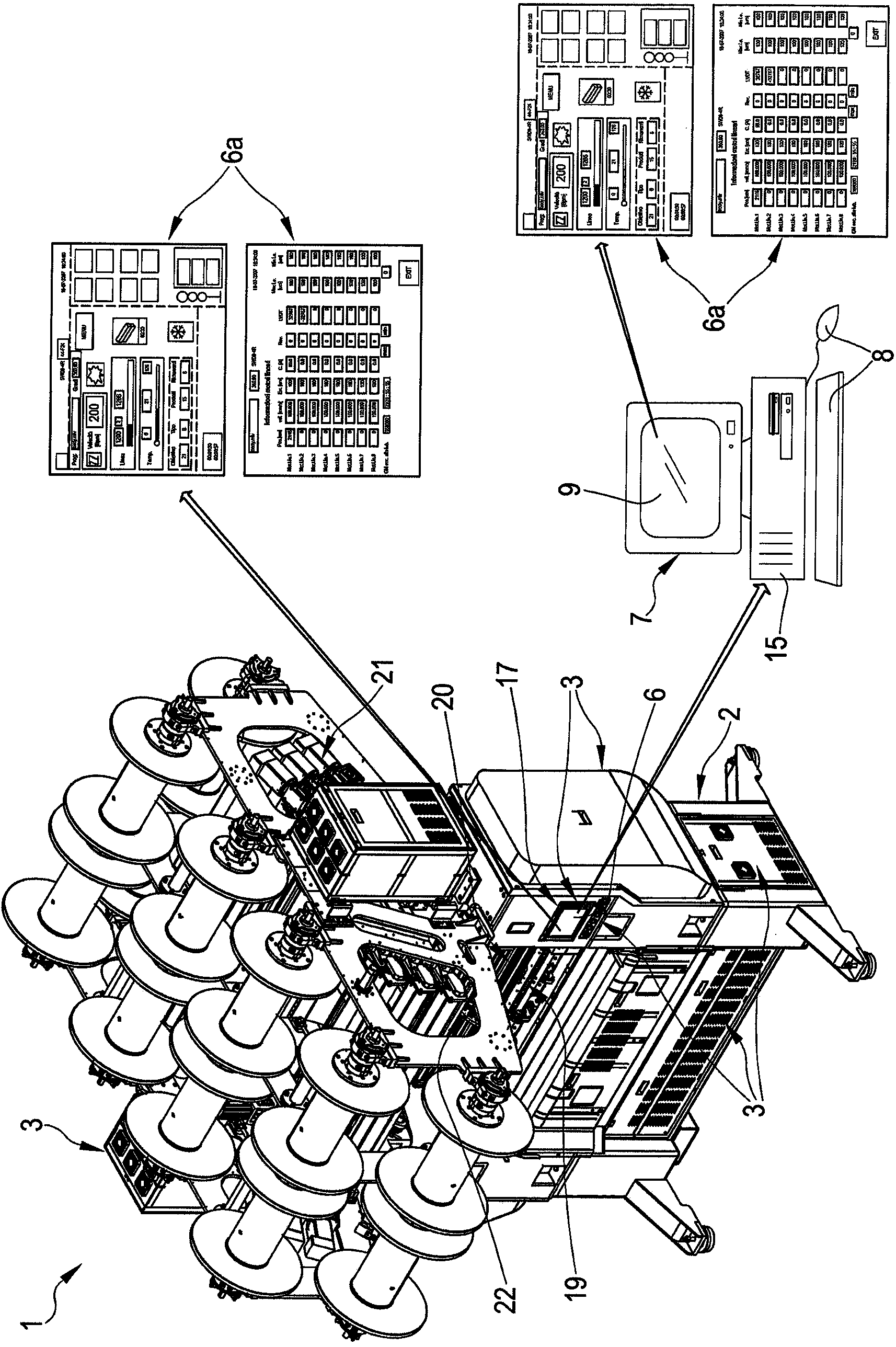

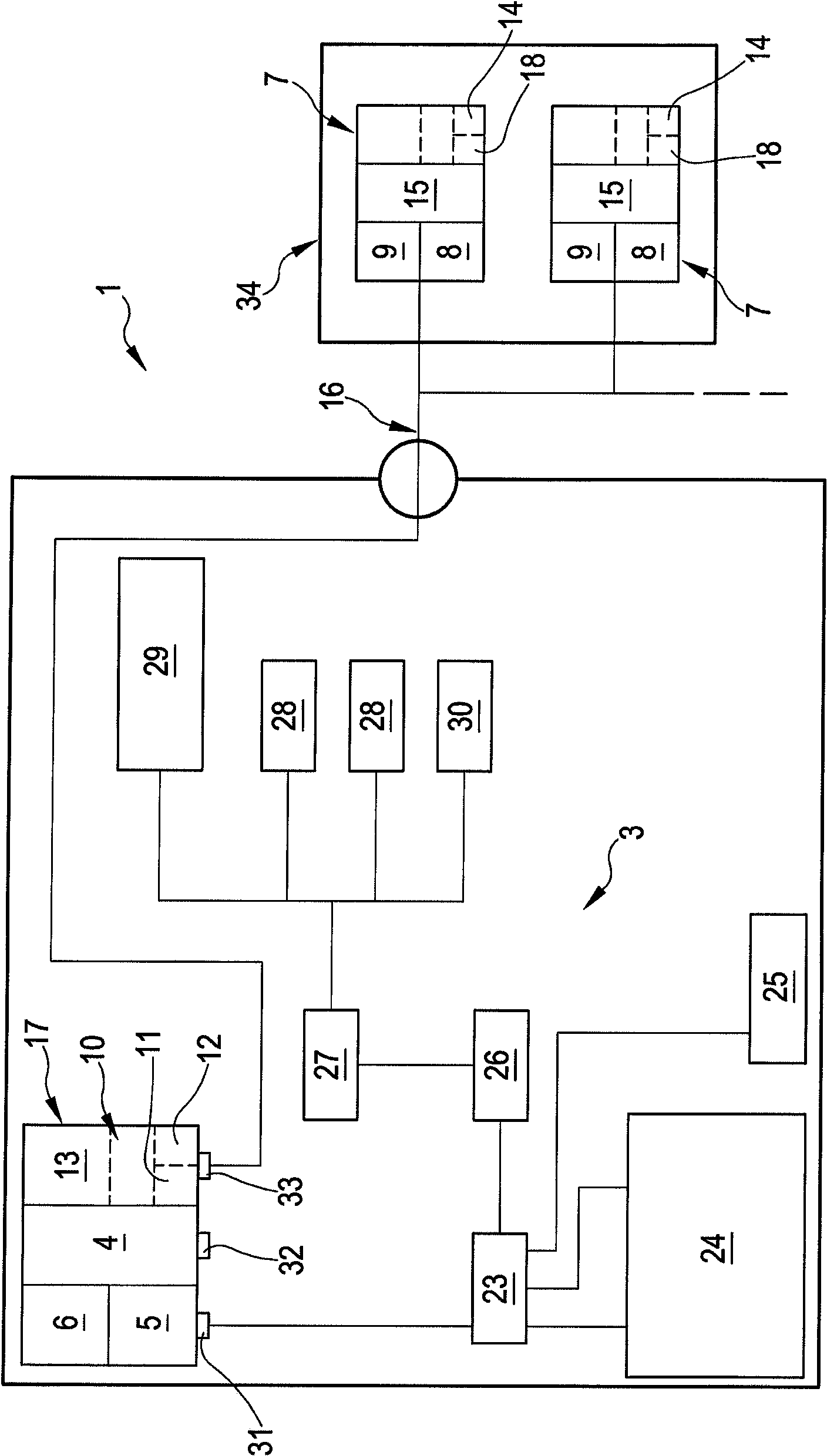

[0040] Referring to the drawings, reference numeral 1 designates a textile machine for warp knitting as a whole.

[0041] The machine 1 comprises a warp knitted structure 2 .

[0042] The machine 1 for warp knitting further comprises a plurality of components of the conventional type mounted on the load-bearing structure 2, these components comprising: a knitting device 19 (comprising different conventional elements comprising one or two weaving needle beds, One or more needle bars, sewing comb bars, possibly also marking bars), at least one needle thread guide bar 20 (needle thread guide bar) for guiding the yarn to the knitting device 19, (preferably) fixed or A plurality of needle bars 20 of jacquard type, and at least one device 21 which supplies yarn to the needle bars 20 and to the knitting device 19 , is mounted above the support structure 2 in the example shown.

[0043] The machine 1 also comprises other components, such as a pulling device for the textile fabric pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com