Deep foundation pit underground grain depot and construction method thereof

A construction method and technology for deep foundation pits, which can be used in infrastructure engineering, excavation, artificial islands, etc., and can solve the problems of many consumables and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

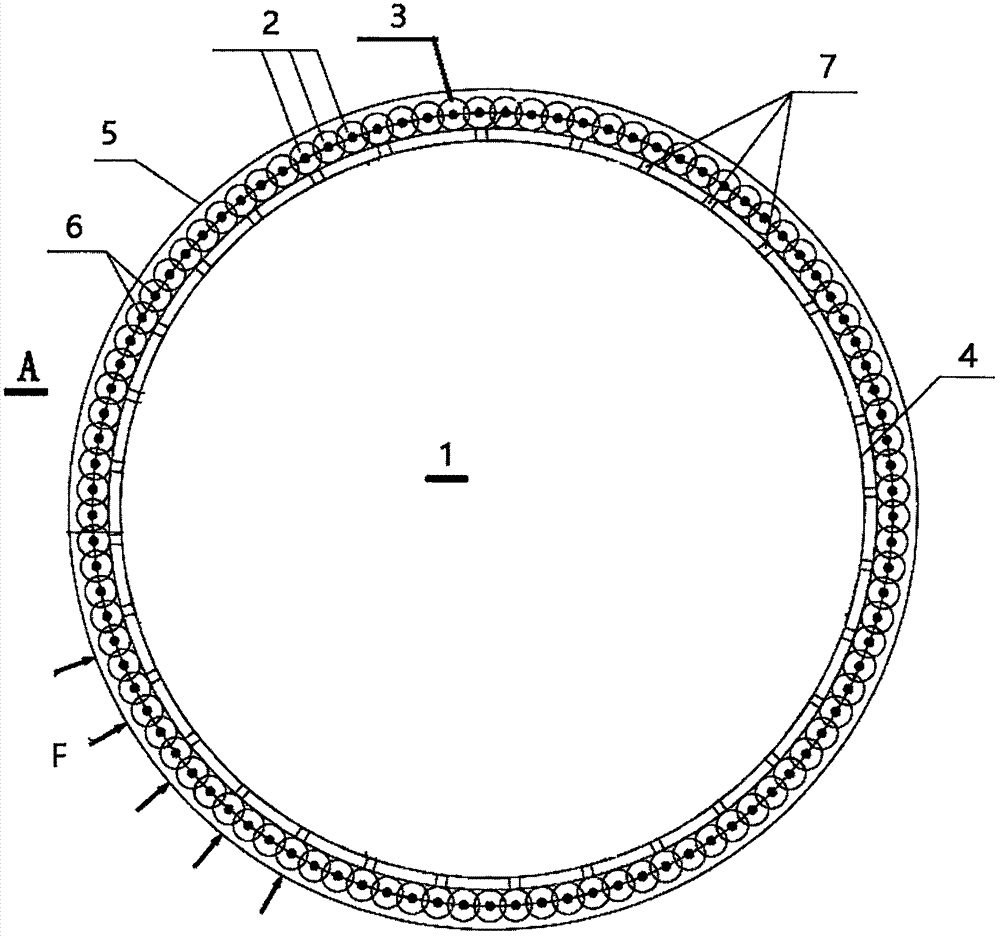

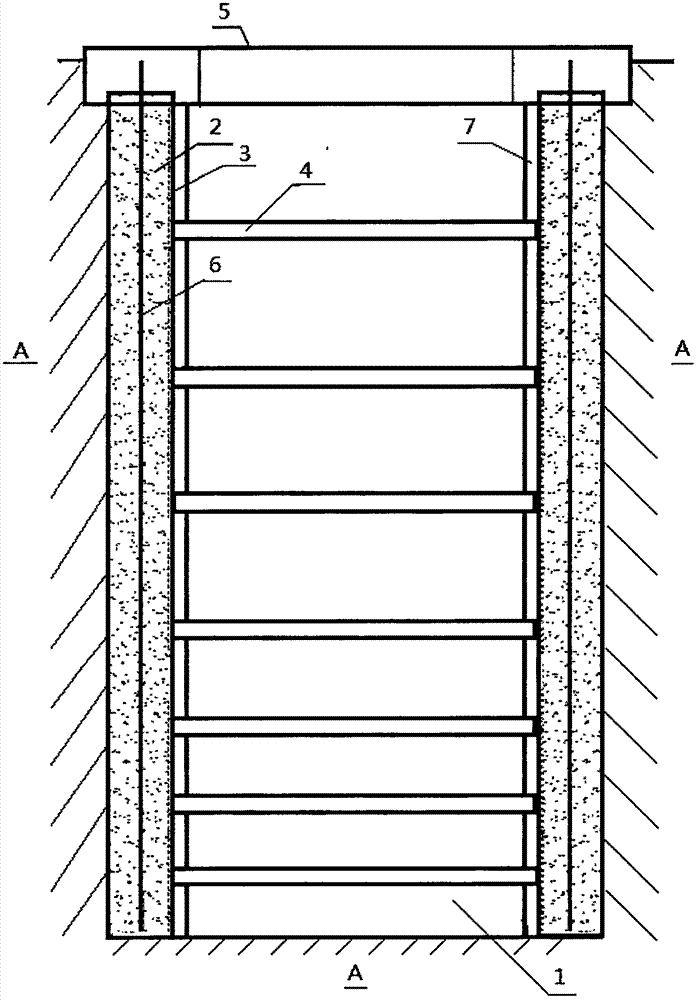

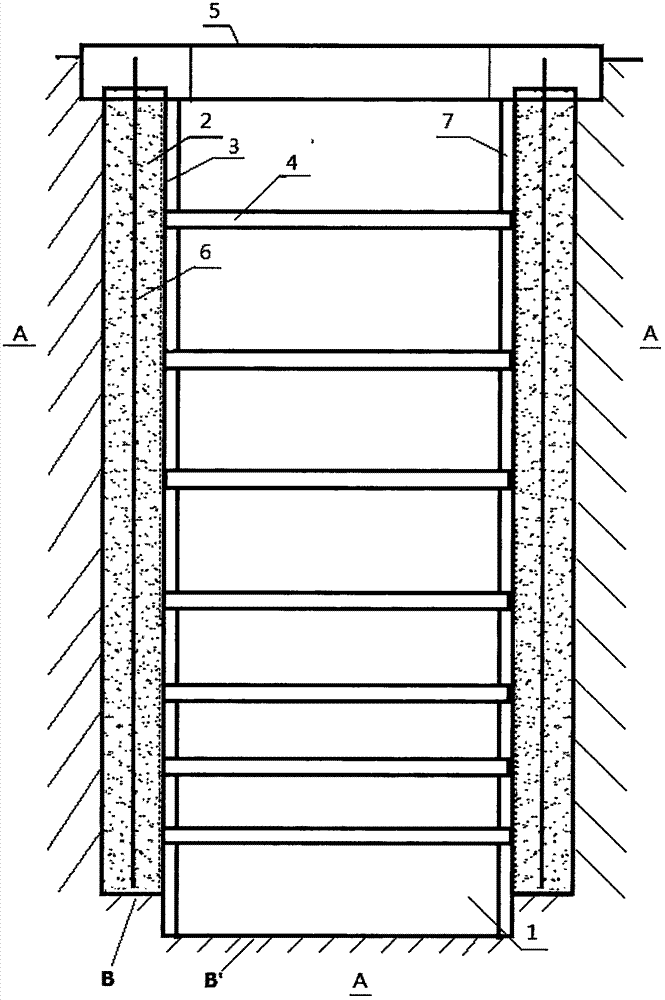

[0043] Such as figure 1 As shown, an underground grain storage with a deep foundation pit includes: a foundation pit 1, the foundation pit is in the shape of a barrel; several pile bodies 2 are arranged circularly along the pit wall of the foundation pit 1, and are interlocked together , forming a circumferentially closed retaining wall 3; the internal support structure 4 is arranged circularly along the inner wall of the retaining wall 3, and the retaining wall 3 is supported by the inner side of the retaining wall 3 toward the soil A; the pile body The bottom end of 2 is located on the bottom surface of the foundation pit 1.

[0044] The deep foundation pit underground grain storage in this embodiment preferably includes: the inner support structure 4 includes at least one inner support ring beam, and the at least one inner support ring beam is annularly arranged along the inner wall of the retaining wall 3 .

[0045] The deep foundation pit underground grain storage in thi...

Embodiment 2

[0053] This embodiment discloses a construction method for an underground grain storage in a deep foundation pit, comprising the following steps: a. setting interlocking piles on the leveled construction site, wherein the piles are arranged in a circle; b. .Drill holes on the pile site to form pile holes, pour concrete or cement soil into the pile holes to form several pile bodies interlocking with each other, and the pile bodies are arranged in a ring to form a circumferentially closed retaining wall c. Excavating the soil surrounded by the retaining wall to the design depth, and circularly arranging the inner support structure along the inner wall of the retaining wall, wherein, the inner support structure is directed from the inner side of the retaining wall to the soil forming support for the retaining wall, and the design depth is above the bottom of the pile; d. Excavating the soil surrounded by the retaining wall above the bottom of the pile to form a foundation pit, An...

Embodiment 3

[0060] This embodiment also discloses a construction method for an underground grain storage in a deep foundation pit, comprising the following steps: a. setting interlocking piles on the leveled construction site, wherein the piles are arranged in a circle; b. Insert several prefabricated piles with an interlocking structure on the pile position, the prefabricated piles are interlocked together through the interlocking structure, and the prefabricated piles are arranged in a ring to form a closed retaining wall; c. The soil surrounded by the retaining wall is excavated to the design depth, and the inner support structure is arranged circularly along the inner wall of the retaining wall, wherein the inner support structure is formed by the inner side of the retaining wall towards the retaining wall Support, wherein, the design depth is above the bottom of the pile body; d. Excavate the soil surrounded by the retaining wall above the bottom end of the pile body to form a foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com