Continuous casting system for casting a metal strand having a billet or bloom cross-section

A continuous casting billet and cross-section technology is applied in the field of continuous casting equipment for casting metal continuous casting billets with a billet or bloom cross-section, and can solve the problem that the guide rollers of the continuous casting billet are difficult to install and align, and are very difficult to install. Difficult to align the mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

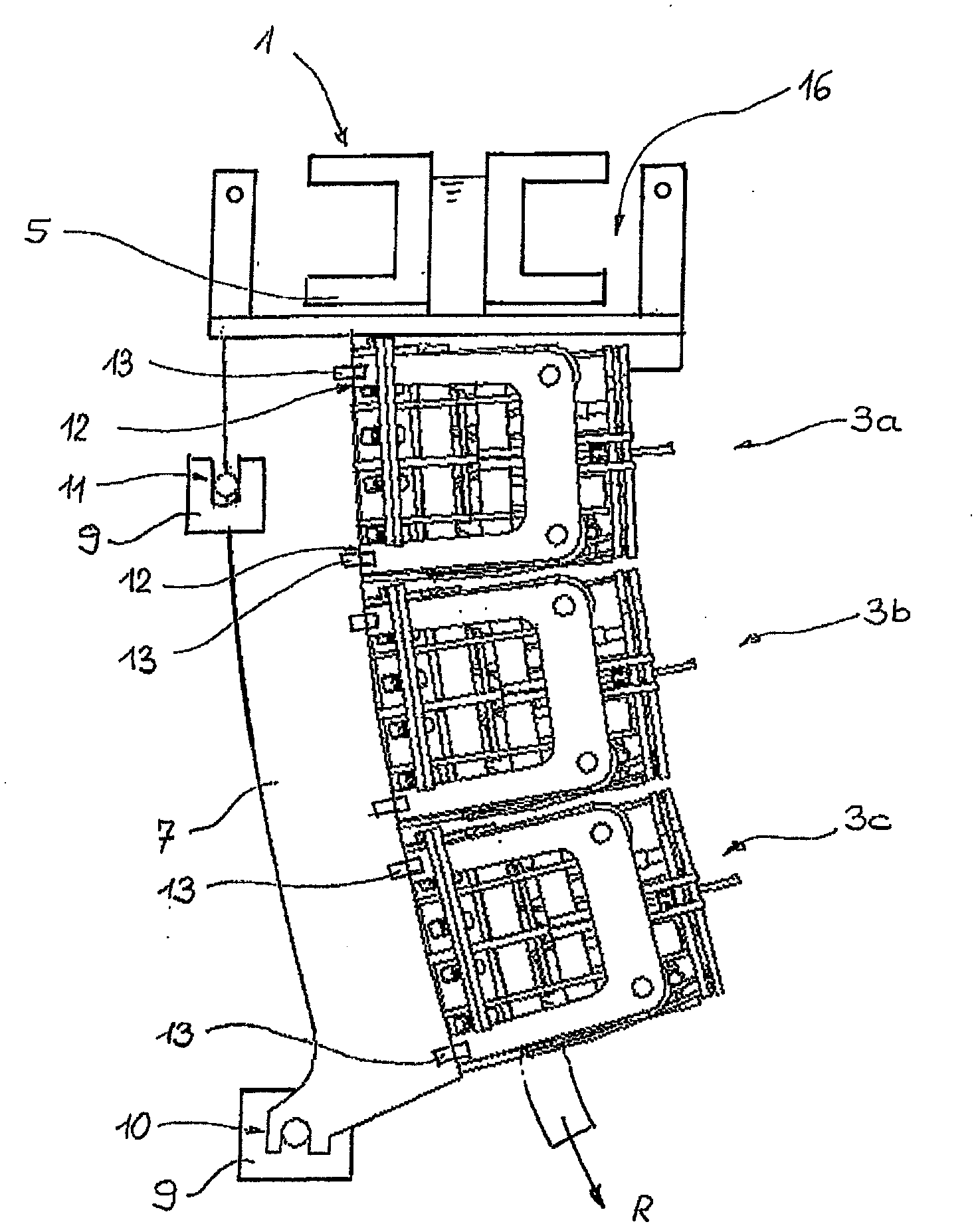

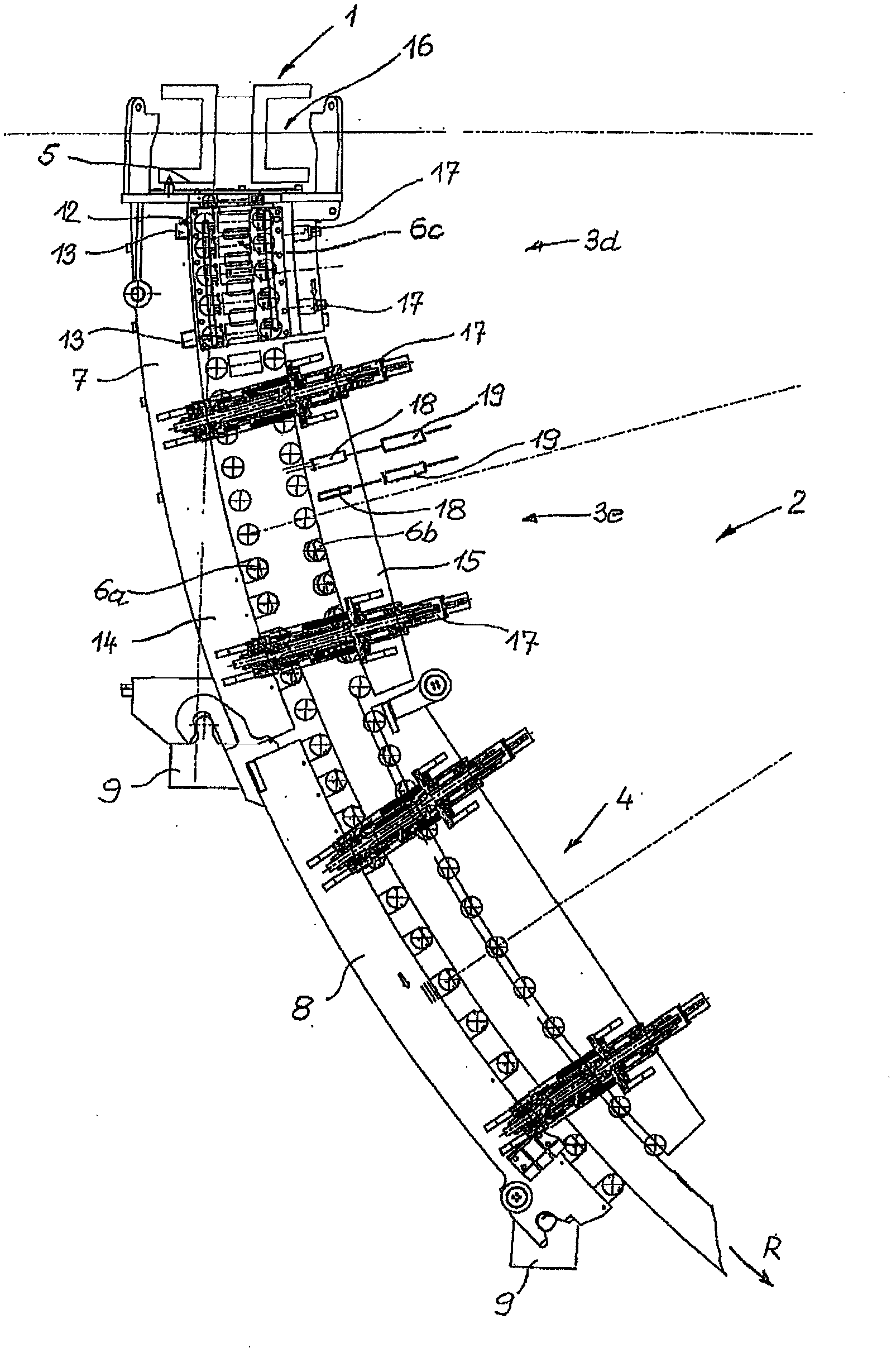

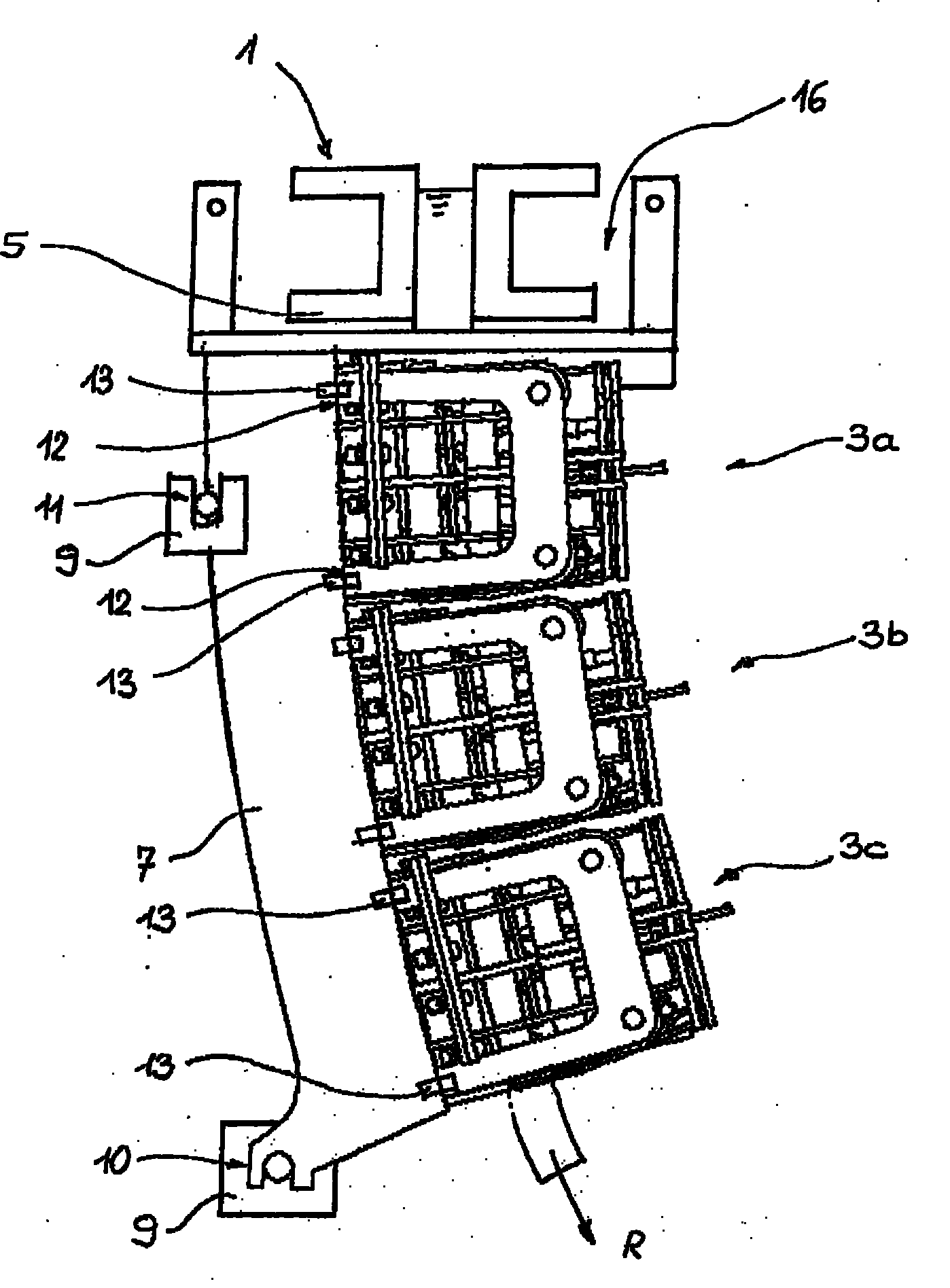

[0020] figure 1 and figure 2 In a schematic partial view, a bloom continuous casting plant is shown, comprising a mold 1 and a subsequent strand guide 2 with a strand guide area Sections, where only the slab guide sections 3a, 3b, 3c, 3d, 3e, 4 directly connected to the mold 1 are shown. In both figure descriptions, identical parts are provided with the same reference numerals.

[0021] The mold 1 is either formed as a tubular mold and is mainly used to cast metal continuous casting slabs with a billet cross section; or is formed as a plate mold and is mainly used to cast metal continuous casting slabs with a bloom cross section. The crystallizer 1 is equipped with an internal cooling not shown in detail (this internal cooling corresponds to the prior art) and is suspended in an oscillating manner on a crystallizer support frame 5 .

[0022] After the metal slab is discharged from the crystallizer 1, it is guided by the slab guide mechanism 2 composed of the slab guide sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com