I-type impact air flow attenuator

A technology of attenuator and air flow, which is applied in container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve problems such as impact vibration, achieve energy dissipation, ensure exhaust flow requirements, reduce pipe The effect of road coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

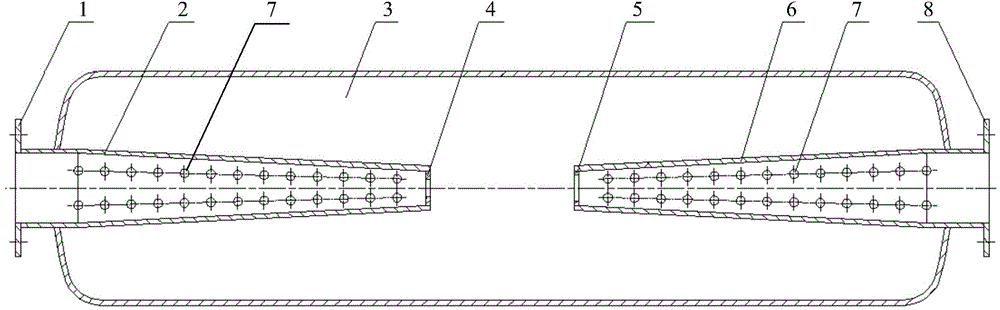

[0018] see figure 1 , the present invention comprises an airflow buffer chamber 3, the two ends of the airflow buffer chamber 3 are equipped with an air inlet pipe 2 and an air outlet pipe 6 communicating with the inner cavity of the airflow buffer chamber 3, and the inner diameter of the air inlet pipe 2 and the air outlet pipe 6 is from the front end to the rear The end is a tapered structure; the length of the airflow buffer chamber 3 is 10 to 14 times the inner diameter of the inlet pipe 2 or the outlet pipe 6, and the width is 3 to 3.5 times the inner diameter of the inlet pipe 7 or the outlet pipe 4; the inlet pipe 2 and the outlet pipe 6 is a 1Cr18Ni9 austenitic stainless steel porous pipe with several through holes 7 on the pipe wall, the diameter of the through holes 7 is 1 / 8 to 1 / 7 of the inner diameter of the air inlet pipe 2 or the air outlet pipe 6; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com