Non-contact type surrounding rock stress release method based on high pressure waterjet

A non-contact technology of surrounding rock stress, applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of high construction cost, poor unloading capacity, and consumption, so as to improve construction safety, reduce production cost, and achieve huge The effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

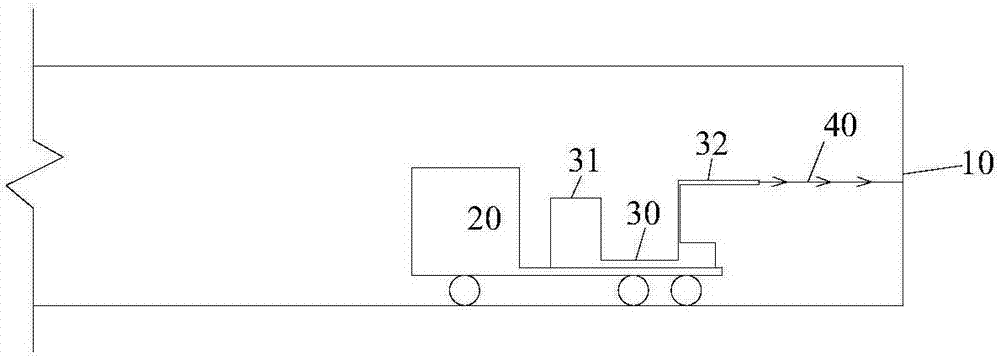

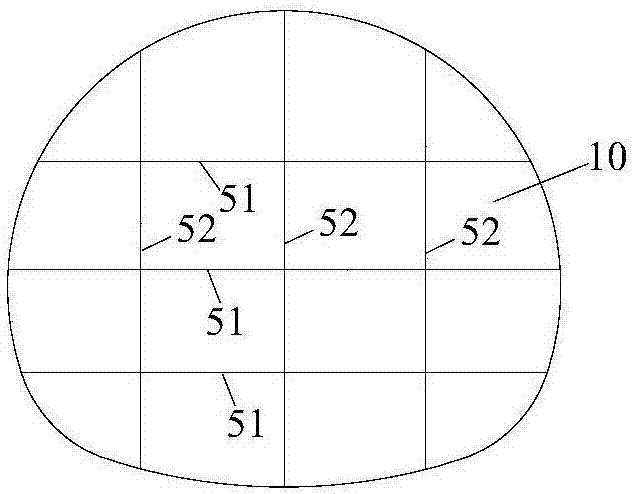

[0017] refer to figure 1 , a non-contact surrounding rock stress release method based on high-pressure water jets in the present invention is to move the vehicle-mounted platform 20 carrying the high-pressure water jet device 30 to a certain distance from the face 10, and start the high-pressure water jet device 30 to utilize The high-pressure water beam 40 generated by the high-pressure pump 31 cuts from the surface of the face 10 to the deep surrounding rock to form a groove with a certain depth and width, and releases the stress of the surrounding rock through the groove and cutting water flow. During the cutting process, the impact of high-pressure water is used to clean the rock and soil in the groove, and the softening effect of water on the rock and soil can further release part of the stress. This process can prevent workers from constructing n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com