Latch needle

A latch needle and latch groove technology, applied in the field of latch needle, can solve the problems of needle no longer working correctly, lost, latch spring sliding, etc., and achieve the effect of increasing the rigidity of the needle bar, reducing the requirement and increasing the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

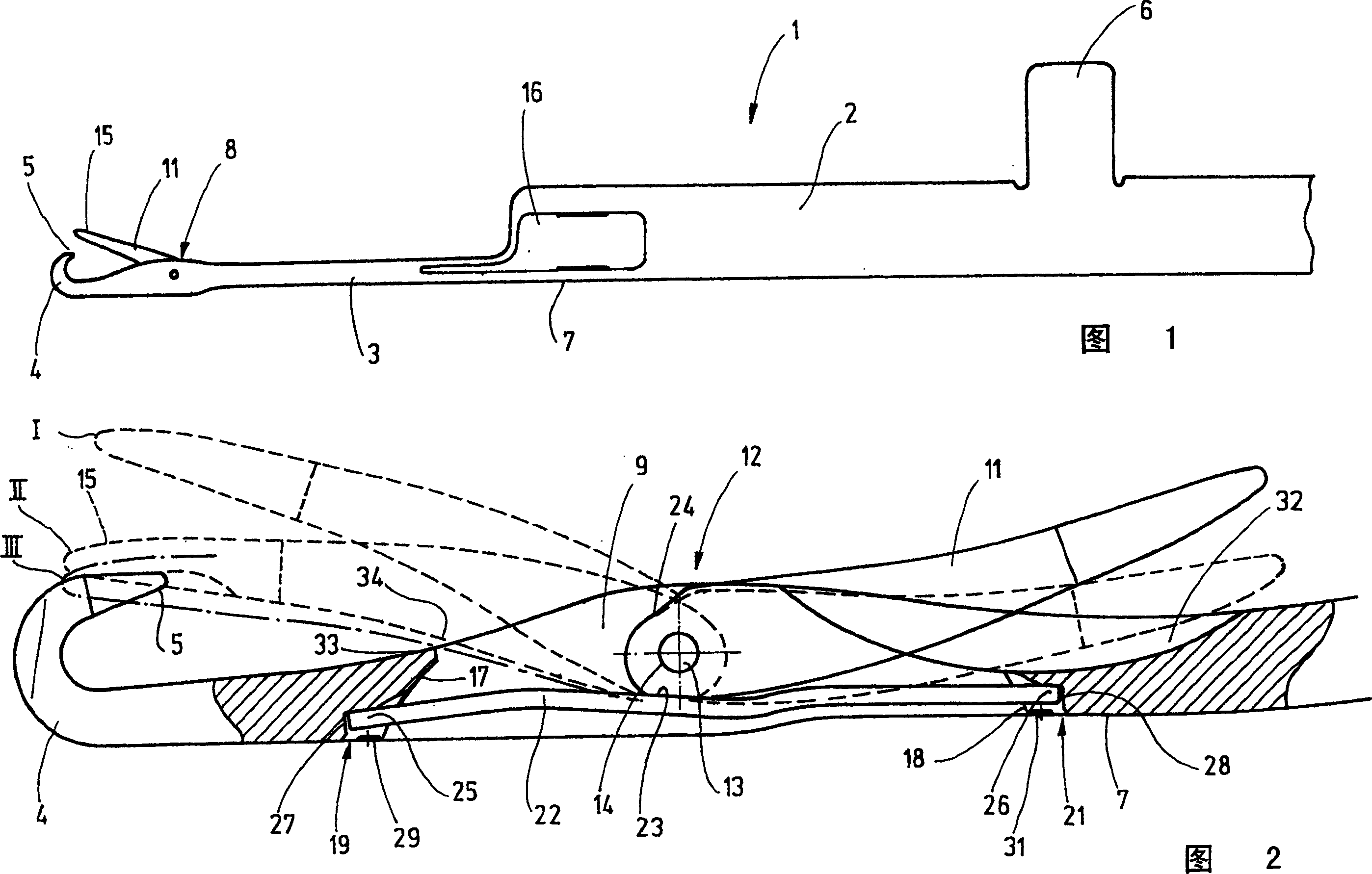

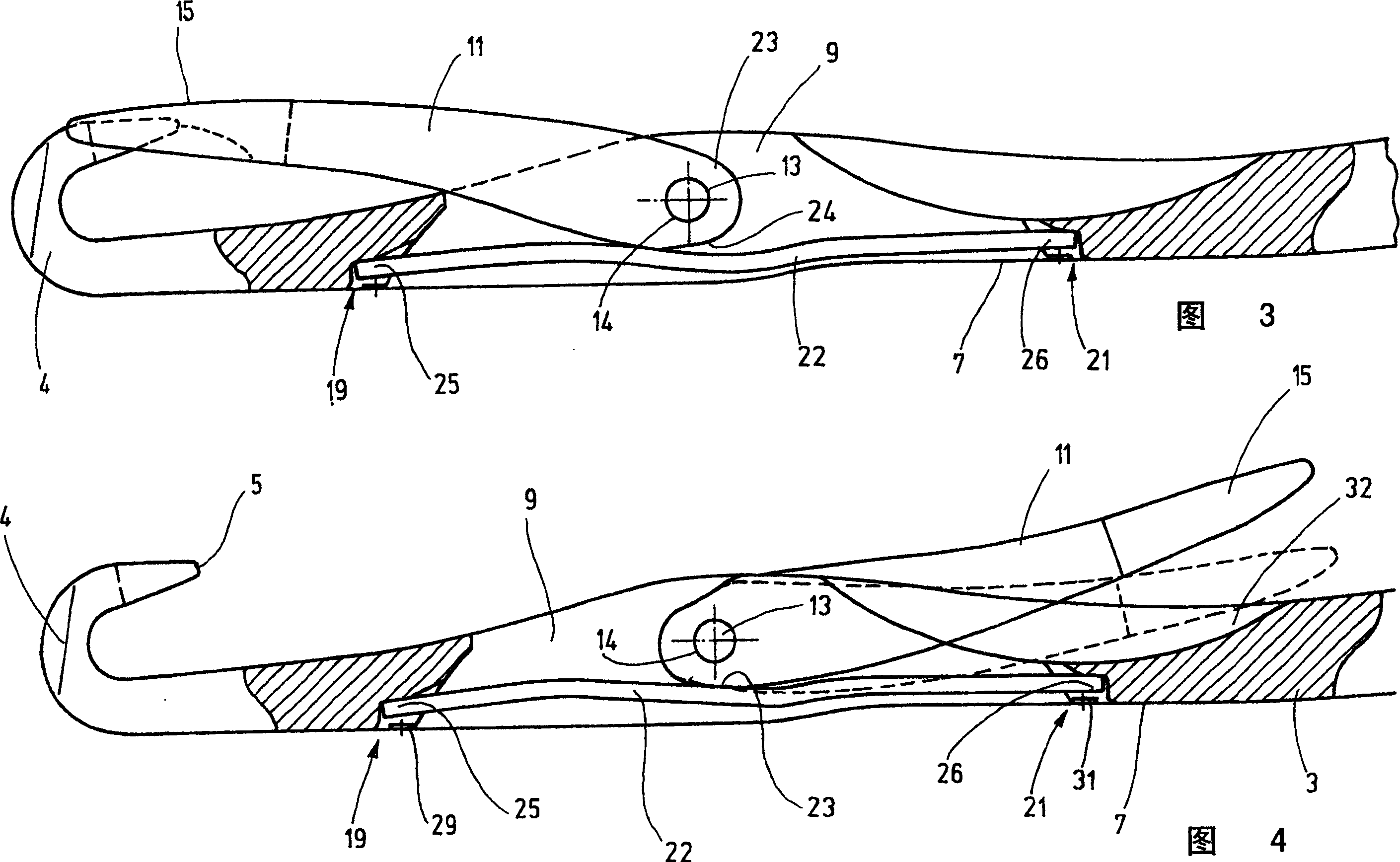

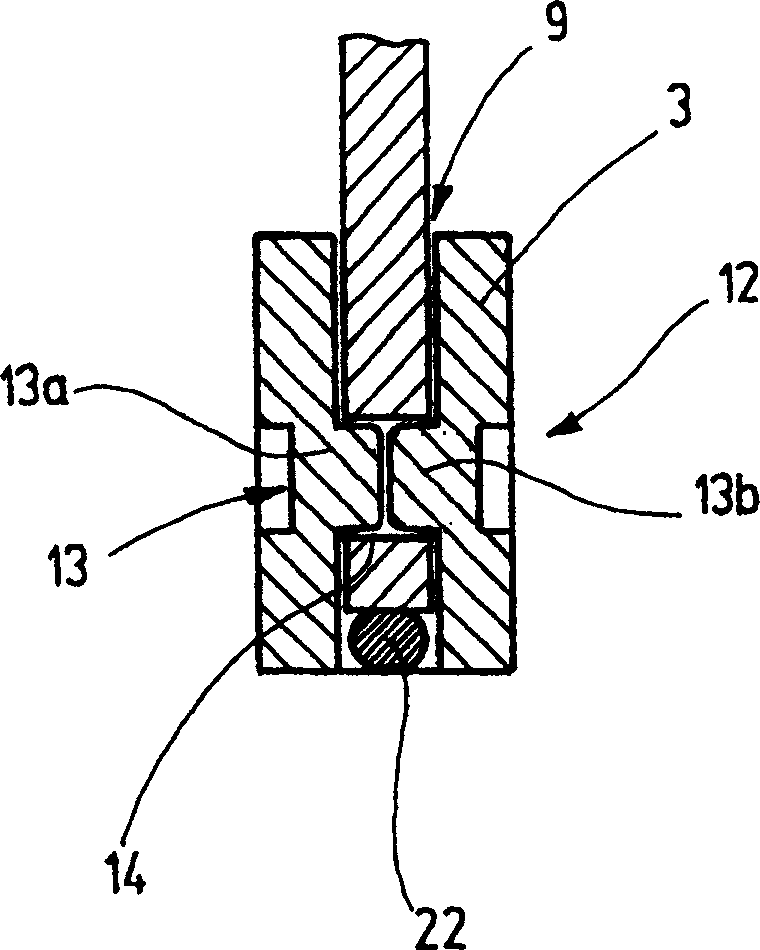

[0025] Figure 1 depicts a latch needle 1, which is mainly used as a machine knitting needle, or similarly as a knitting needle or the like. The latch needle 1 has a base body 2 delimited by two flat sides, from which a needle shaft 3 extends. The free end of the needle shaft 3 carries the needle hook 4 , and the tip 5 of the needle hook 4 points towards the base body 2 . In FIG. 2 , the lower narrow side of the base body 2 and the needle bar 3 away from the hook 4 and the stitch 6 of the latch needle 1 forms a needle back 7 . In FIG. 1 , the upper narrow side of the needle shank 3 forms a needle belly 8 at least immediately adjacent to the needle hook 4 . In the region of the needle belly 8 , the needle shaft 3 is provided with a tongue and groove 9 , which can be seen in longitudinal section FIG. 2 . The tongue groove 9 is used to accommodate one end of a needle latch 11 which is swingably supported by a supporting device 12 . The bearing means 12 is formed by a bearing 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com