Multi-track sorting trolley conveying mechanism

A sorting trolley and conveying mechanism technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of increasing the bearing capacity of the rack, increasing the weight of the device, and being unbearable, and reducing the weight and simplifying the structure. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

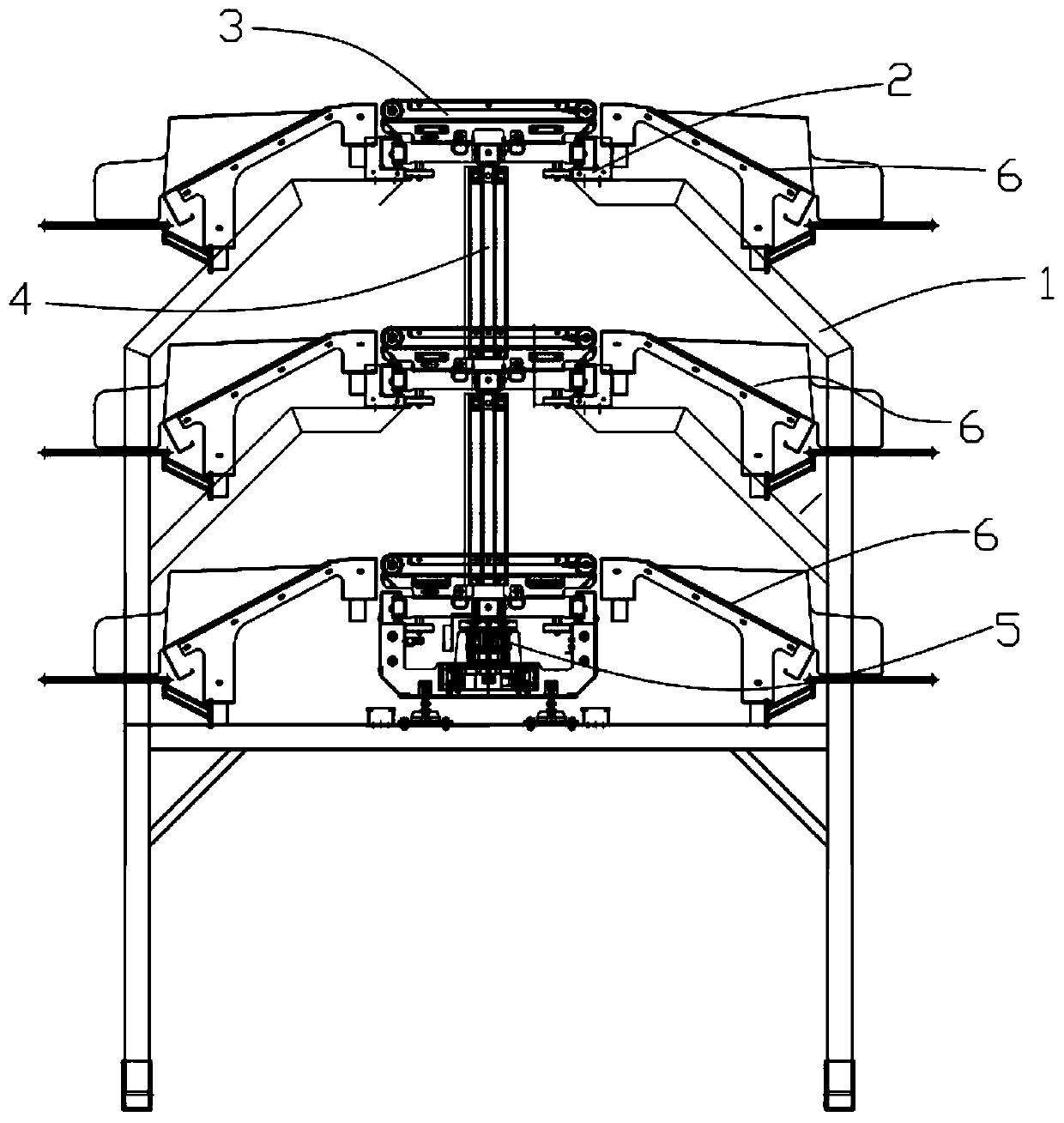

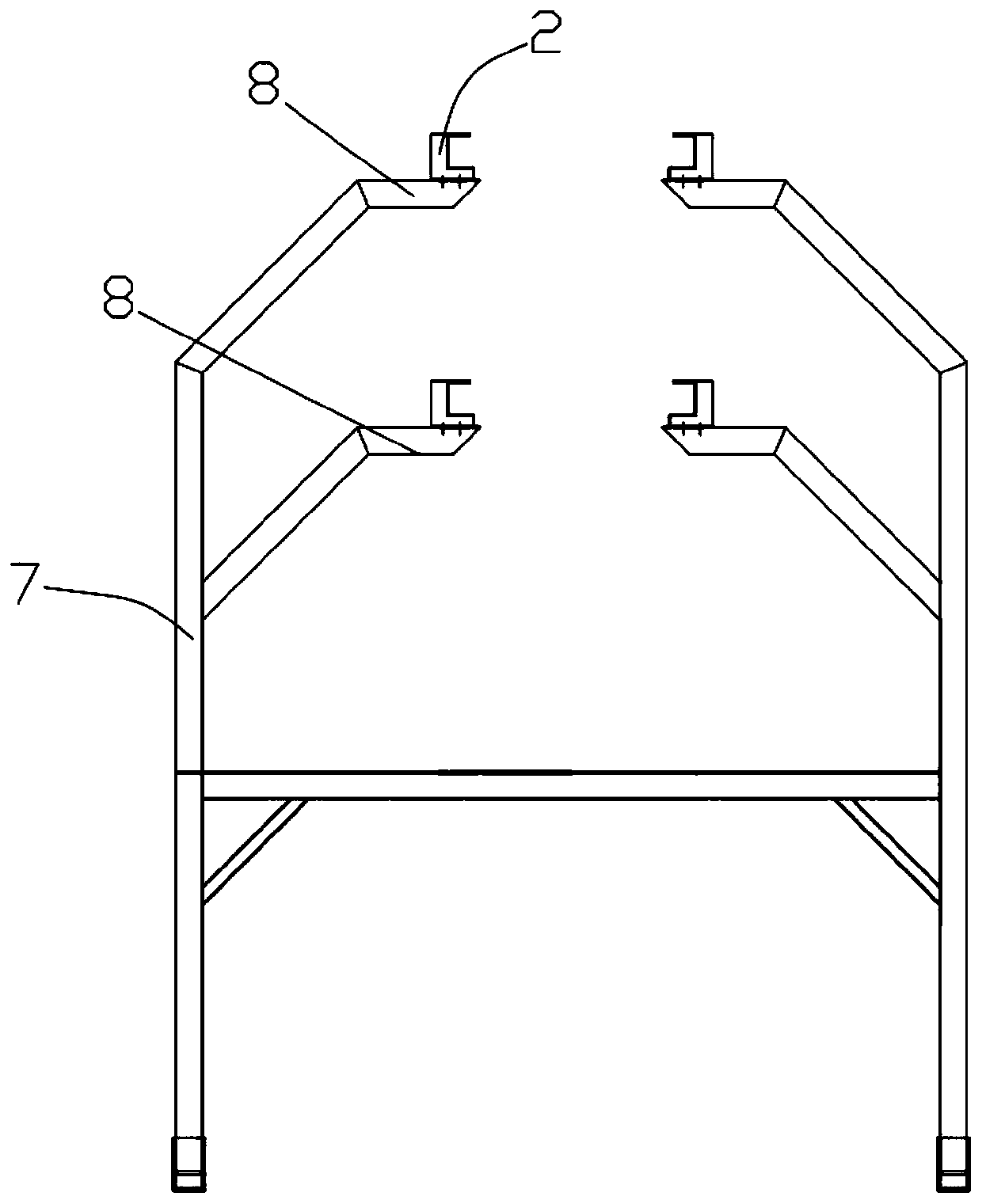

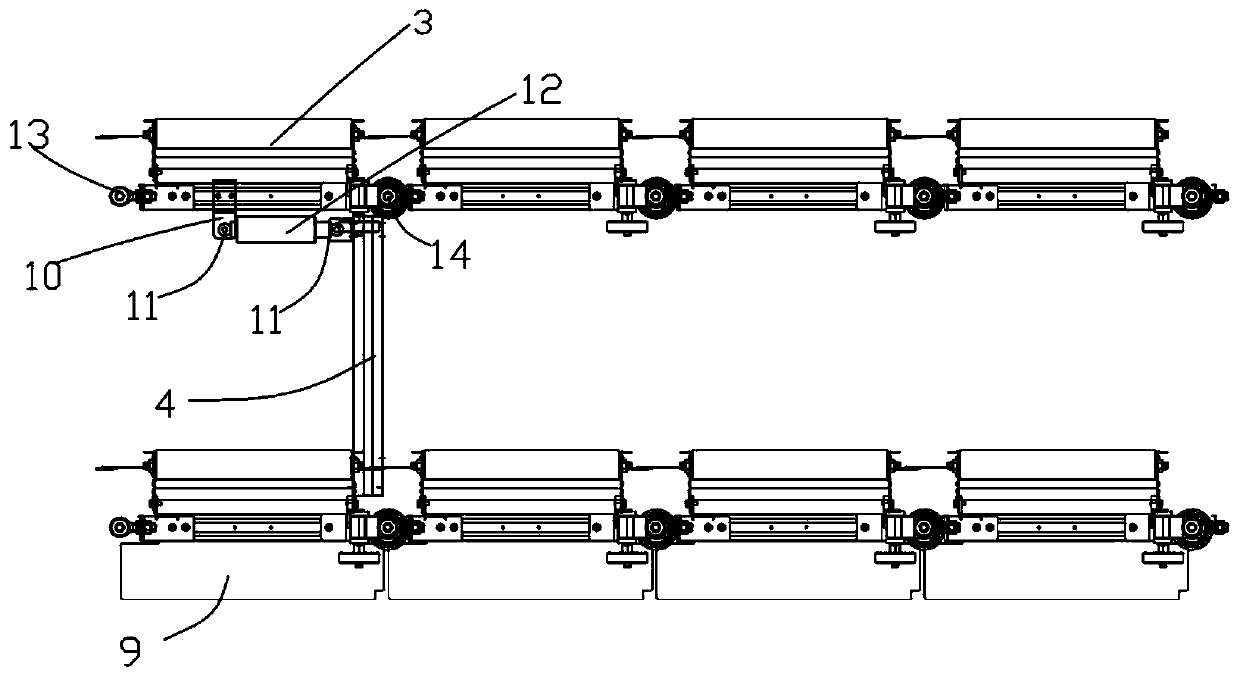

[0022] Such as figure 1 , image 3 As shown, the present invention proposes a multi-track sorting trolley conveying mechanism, which includes at least two layers of support frame 1, and the support frame 1 is provided with a multi-layer slide rail 2, and the slide rail 2 is provided with several trolleys 3 , the trolleys 3 are arranged continuously at the head and tail, the trolleys 3 on different floors are provided with connecting rods 4, and the connecting rods 4 are used to connect one group of corresponding trolleys 3 on the upper and lower floors, and the bottom of the support frame 1 is provided with a drive The power mechanism 5 for the movement of the trolley 3, wherein the structure of the trolley 3 is a relatively mature design of the trolley 3, and a U-shaped supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com