Support method for extra-thick broken coal seam employing nest anchored ropes

A bird's nest and anchor cable technology, which is applied in the direction of earthwork drilling, temporary shielding, bolt installation, etc., can solve the problems of lack of support and reinforcement methods, and achieve good support effects, reduced deformation, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

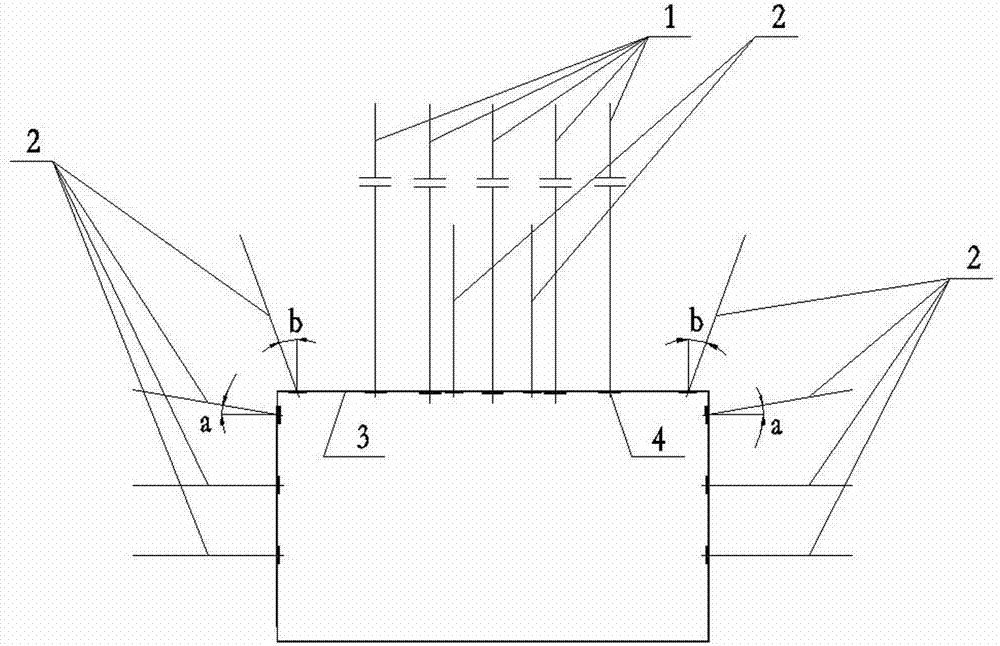

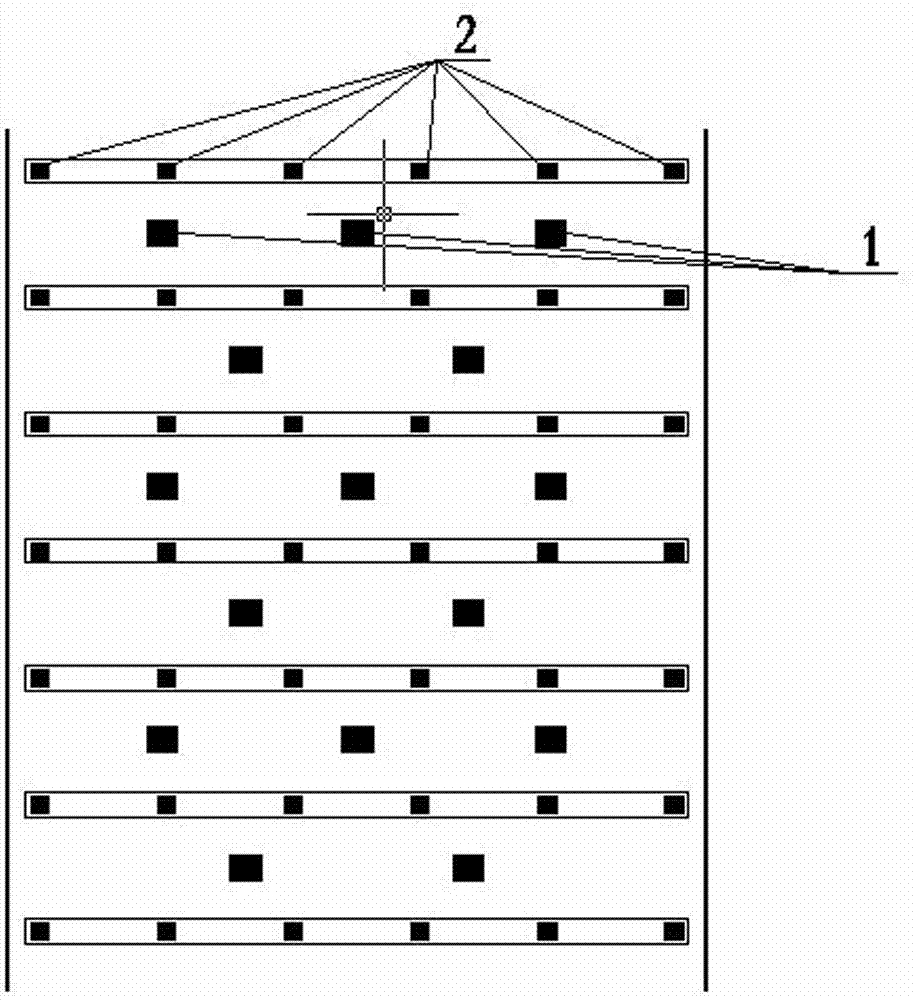

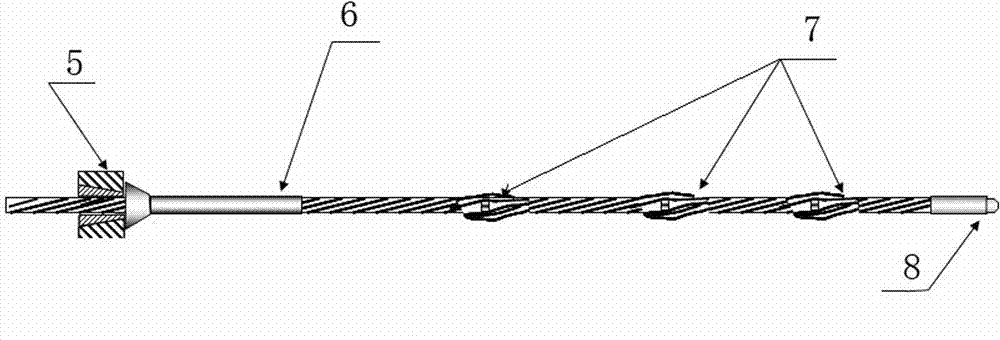

[0012] The supporting method using "bird's nest" anchor cables for extra-thick broken coal seams includes the following steps: fixing several rows of anchor rods 2 on the roof, and each row of roof anchor rods includes four vertically arranged anchor rods in the middle and four anchor rods on both sides. Two inclined bolts are arranged inclined outward. The angle b between the inclined bolt of the roof and the vertical plane is 20°. The diameter of the roof bolt is 18mm and the length is 2200mm. The anchor rod spacing is 820mm, the row spacing of the roof anchor rods is 1000mm, W steel strips 4 are fixed at the lower end of each row of roof anchor rods, and a metal mesh 3 is fixed between every two adjacent W steel strips 4 and the top plate; Corresponding to the two gangs of the roof anchor rods, a row of anchor rods 2 is fixed respectively, and each row of anchor rods includes two anchor rods 2 arranged horizontally and an upwardly inclined anchor rod arranged on the upper si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com