A formwork-free concrete single-cabin pipe gallery or multi-cabin pipe gallery and its construction method

A technology that avoids demolition of formwork and concrete. It is applied in construction, artificial islands, and infrastructure engineering. It can solve problems such as internal quality problems that are difficult to detect and repair, relatively large impact on building quality, and leakage of prefabricated component assembly structures. Easy surface protection treatment and decoration, improved overall strength and anti-seepage performance, and easy formwork support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

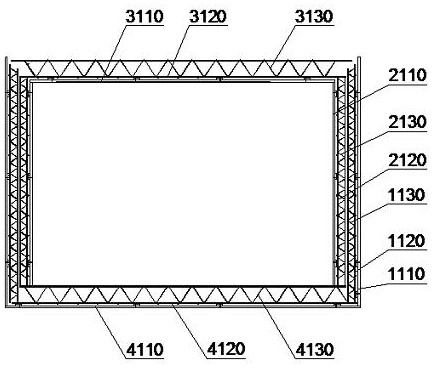

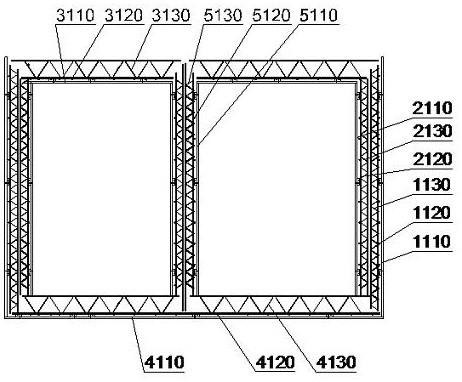

[0071] see Figure 1-2 , the pipe gallery can be a single-cabin pipe gallery ( figure 1 shown), or multi-cabin pipe gallery ( figure 2 shown). When it is a single-cabin pipe gallery, there is no partition wall in the pipe gallery, and when it is a multi-cabin pipe gallery, there is a partition wall in the pipe gallery.

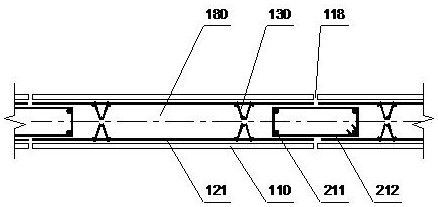

[0072] The pipe gallery is composed of a wall, a bottom plate and a top plate, which will be connected to each other as a whole.

[0073] The wall of the pipe gallery includes the outer wall, and when there is a partition wall, it also includes the partition wall. The outer wall and the top and bottom plates are enclosed in a closed pipe shape, and the cross-section is usually rectangular. The partition wall (if any, the same below) is parallel to the outer wall, dividing the inner space of the pipe gallery into multiple areas to form a multi-cabin pipe gallery.

[0074] The wall adopts a cast-in-place reinforced concrete structure, and the top and botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com