Underground coal mining area type non-excavation-roadway and non-chain-pillar coal mining method

A coal mining method and technology without coal pillars, applied in ground mining, earth drilling, underground mining, etc., can solve the problems of high excavation costs, long excavation time, waste of coal resources, etc., to reduce excavation costs and reduce excavation personnel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

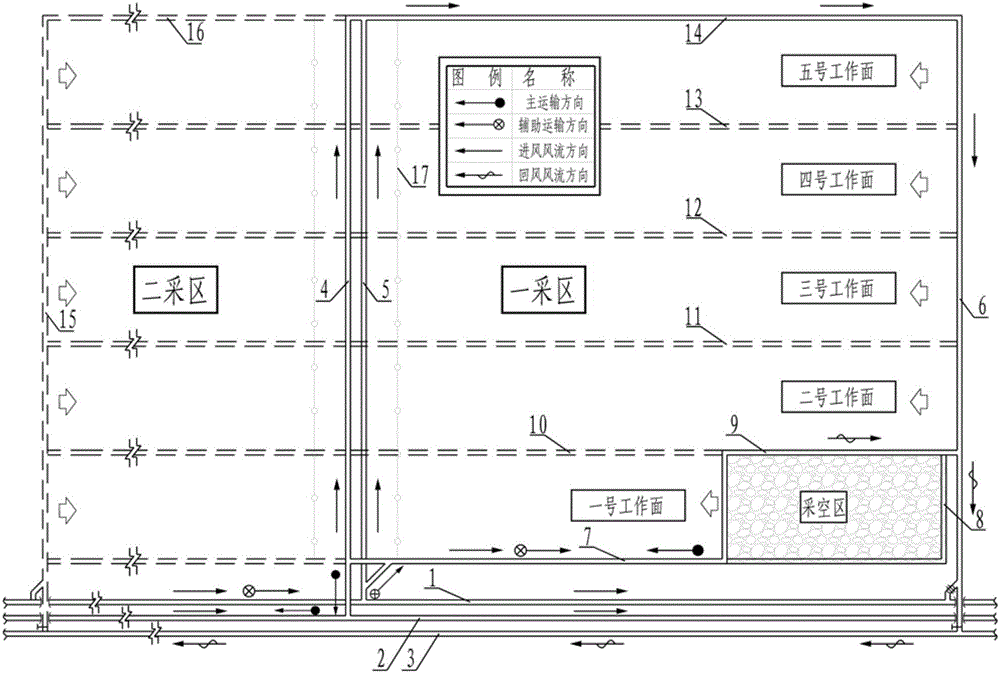

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] like figure 1 As shown, a coal mine has excavated three main lanes: auxiliary transport lane 1, belt conveyor lane 2 and return air lane 3.

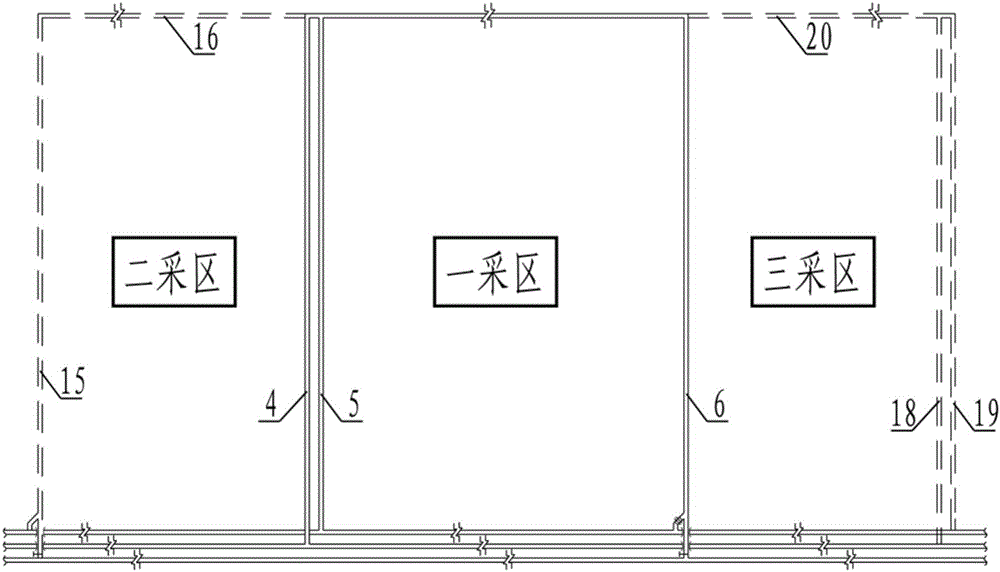

[0044] In addition, it is necessary to excavate the transportation lane 4 of the first mining area and the auxiliary transportation lane 5 of the first mining area in advance. Five coal mining working faces are arranged in between, and the advancing length of the five working faces is the distance between the auxiliary transportation lane 5 in the first mining area and the return air lane 6 in the first mining area. In addition, it is necessary to excavate the air return lane 14 of the No. 5 working face in advance to connect the three mining area lanes to form a mining area ventilation system. The system formed by these three mining area lanes and No. 5 working face return air lanes is the main feature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com