Construction Method of Reinforced Concrete Cast-in-place Pile Without Excavation of Soil Between Pile

A technology of reinforced concrete and construction methods, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of difficult control of pile foundation construction quality, heavy construction environmental pollution, and difficult construction, so as to achieve easy control of the construction process, The construction method is simple and the construction cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

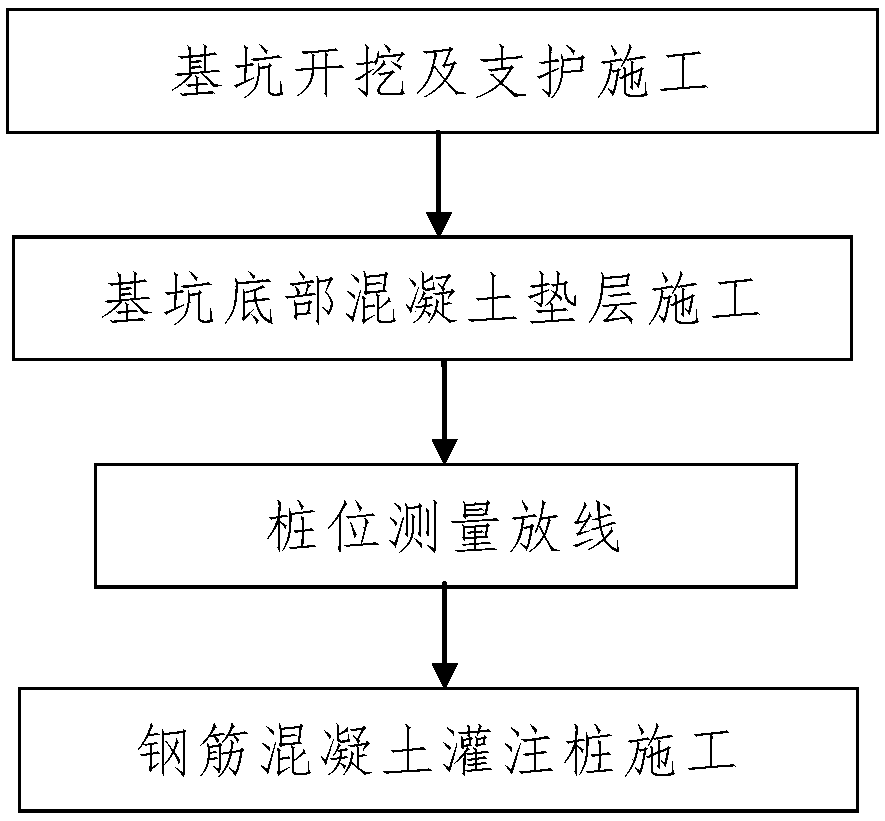

[0043] Such as figure 1 A kind of reinforced concrete cast-in-place pile exempting construction method of inter-pile soil excavation comprises the following steps:

[0044] Step 1. Foundation pit excavation and support construction: Excavate the constructed foundation pit from top to bottom, and support the excavated foundation pit;

[0045] Step 2, construction of the concrete cushion at the bottom of the foundation pit: compact the soil at the bottom of the foundation pit described in step 1, and pour a layer of concrete cushion at the bottom of the foundation pit; Cushion;

[0046] Step 3, pile position measurement and setting out: measure and set out the pile positions of all reinforced concrete cast-in-situ piles to be constructed in the foundation pit respectively;

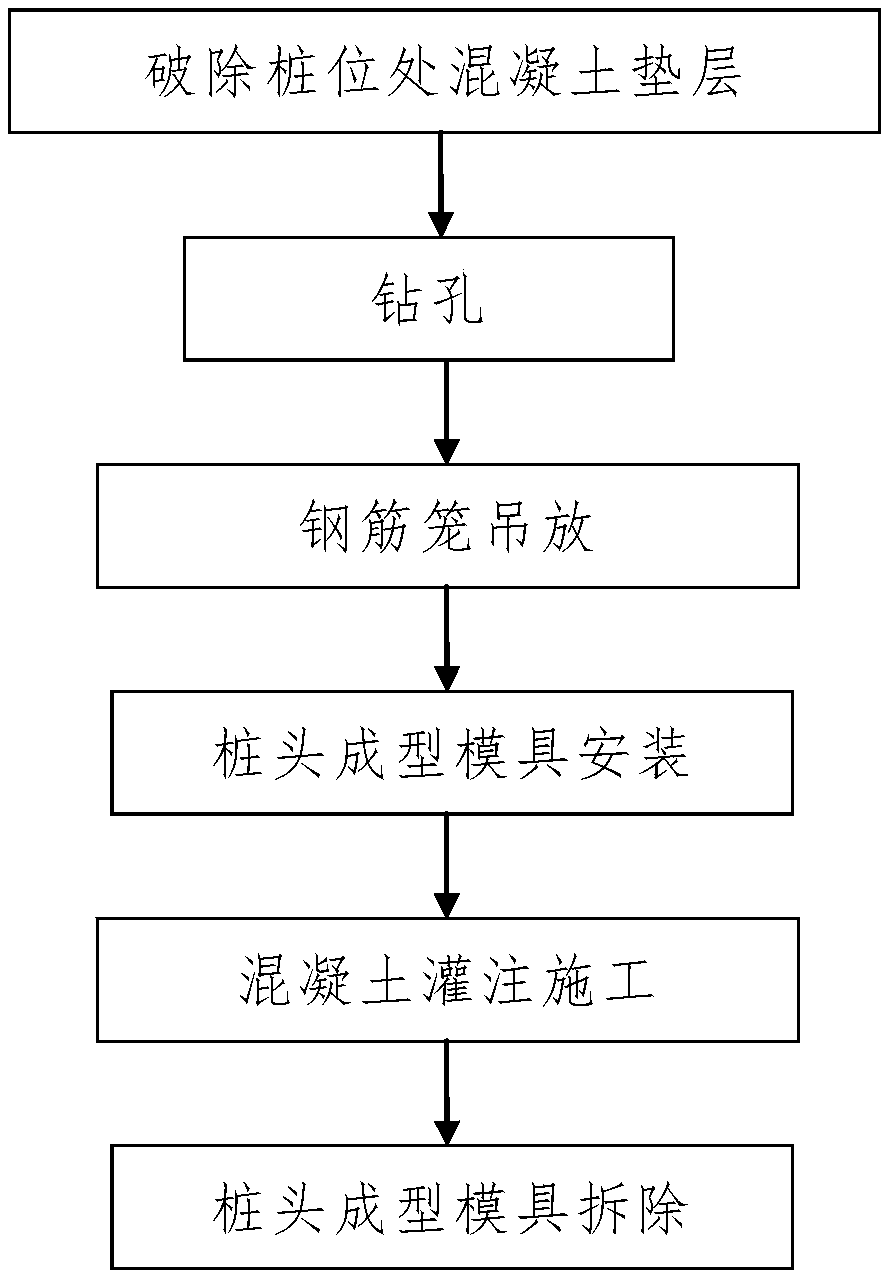

[0047] Step 4, construction of reinforced concrete cast-in-place piles: constructing all reinforced concrete cast-in-place piles to be constructed in the foundation pit respectively, and the construction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com