Pull tube mounting method of passing pipeline

An installation method and pipeline technology, which can be used in pipeline laying and maintenance, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of high construction cost and large restrictions, and achieve low construction cost, safety protection and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

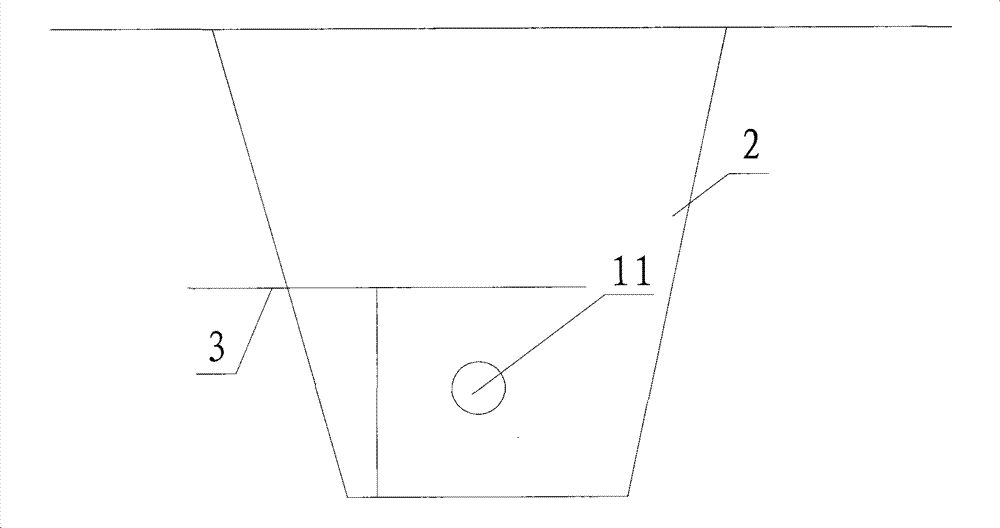

[0023] A pipe-drawing installation method for passing pipelines, the diameter of the engineering pipeline to be installed is 300mm, and the following steps are carried out in sequence:

[0024] Pipeline setting out → excavation of guide trenches → production of pipelines → jacking of conduits → connection of wire ropes → pulling of conduits and wire ropes → pulling of casings → penetration of engineering pipes and installation, the specific steps are:

[0025] When excavating the guide ditch 2, excavate the guide ditch 2 on both sides of the obstacle 1 to be crossed, and fix the limit pile 3 in the guide ditch 2.

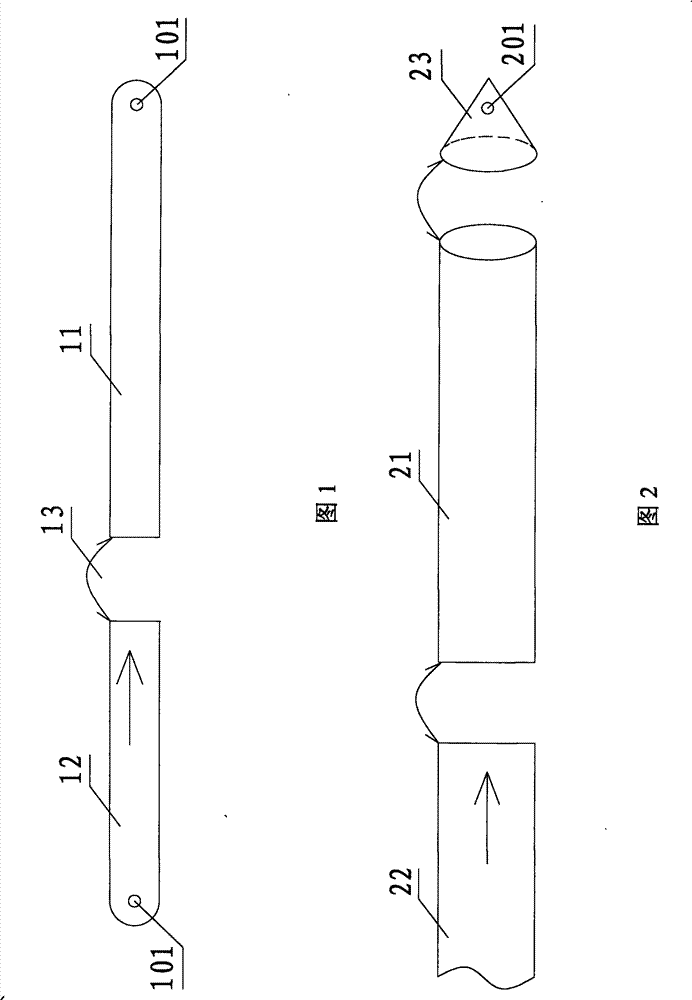

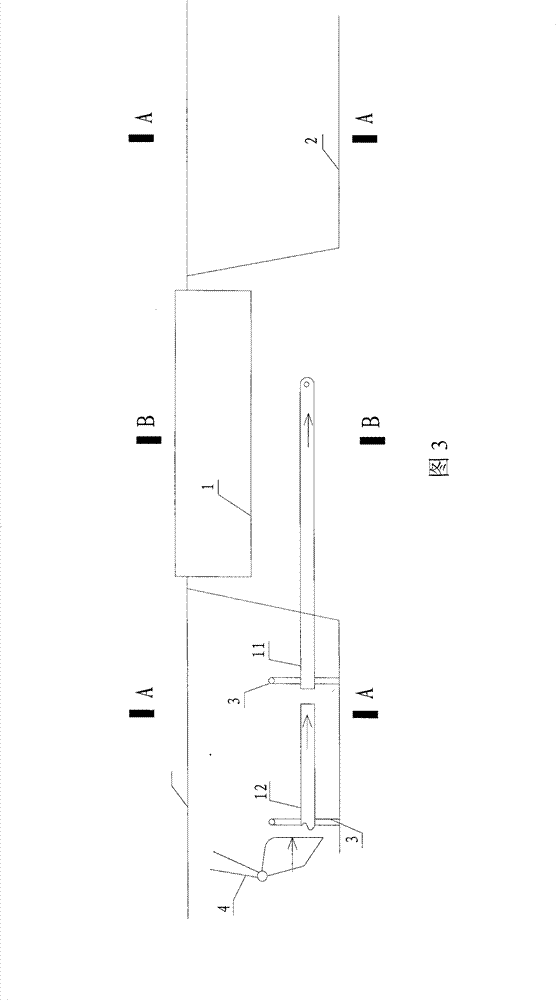

[0026] When making the pipeline, the conduit, as shown in Figure 1, has a diameter of 1 / 5 to 1 / 3 of the diameter of the project pipeline to be penetrated, and the diameter is 100mm. The conduit is divided into two parts, the front conduit 11 and the rear conduit 12. The front conduit 11 The rear portion of the front and rear conduit 12 is provided with a threading h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com