High temperature flame assisted intelligent drilling rig

A drilling rig and flame technology, applied in the application of thermal energy drilling and other directions, can solve problems such as insufficient power, and achieve the effects of reducing excavation costs, increasing construction speed, and reducing the difficulty of excavation and drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

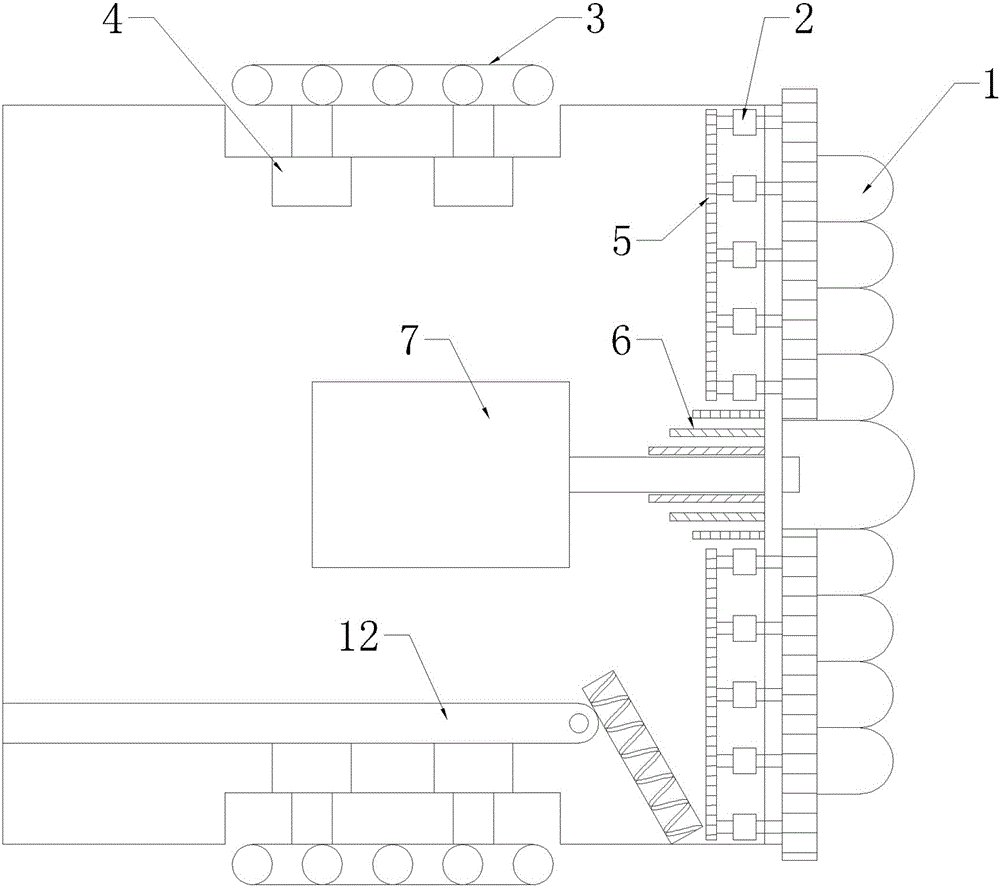

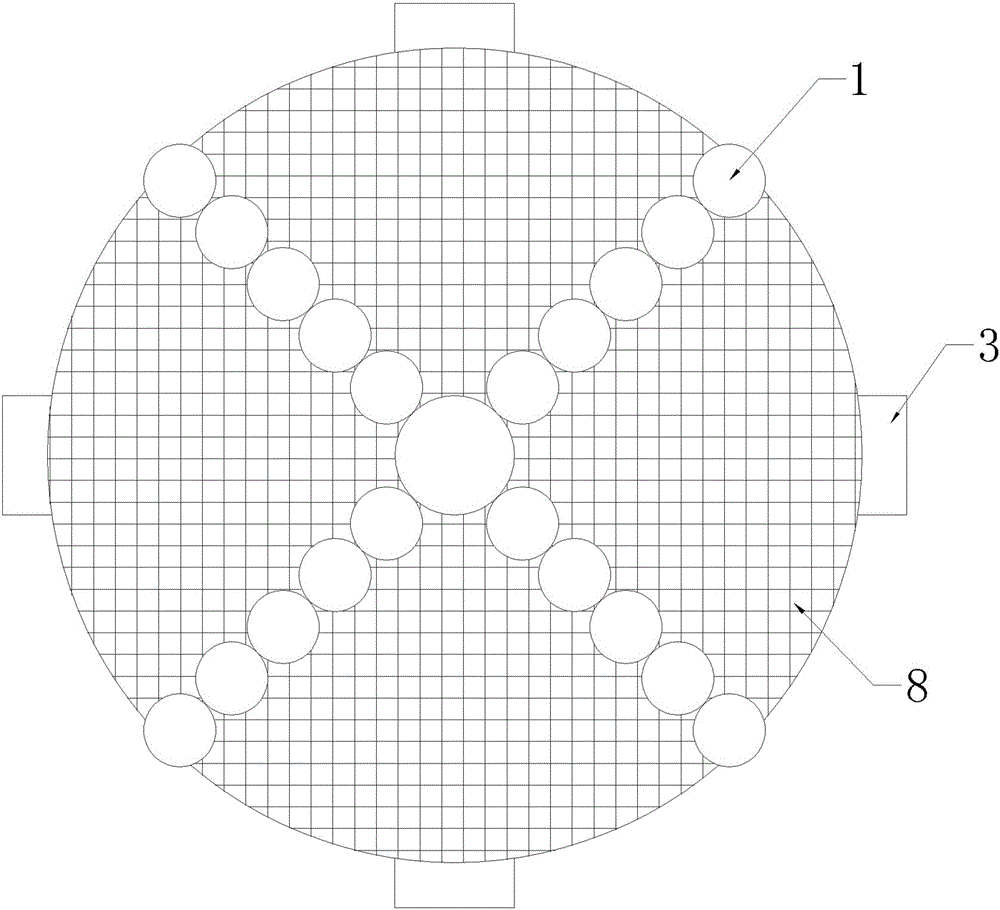

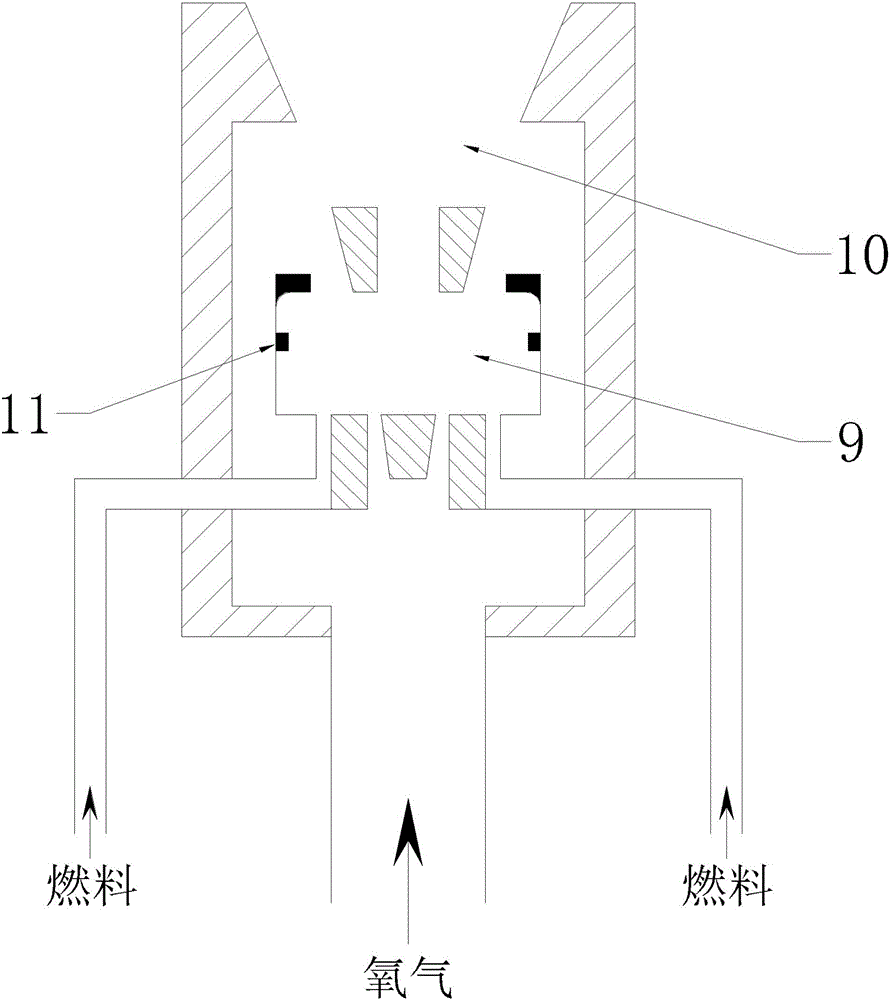

[0027] see Figure 1-4 The high-temperature flame-assisted intelligent drilling rig is composed of three parts: the drilling rig body, the drill platform and the main control system. The drilling rig body includes the fuselage, the crawler advancing system, and the hydraulic support system. Up, down, left, and right four positions, the hydraulic support system includes four groups of hydraulic pumps 4, which are respectively arranged at the positions of the four crawler belts 3; and flame spout 8, the drill bit 1 is a roller cone drill with a water-cooling channel and a water spray hole inside, there are several, installed and fixed on the drill bit seat, the inner side of the drill bit seat is provided with a drill bit motor 2, a drill bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com