Single liftable compound pipe

A composite tube and composite belt technology, which is applied in the direction of lifting frame and lifting device, etc., can solve the problems of small equipment height and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

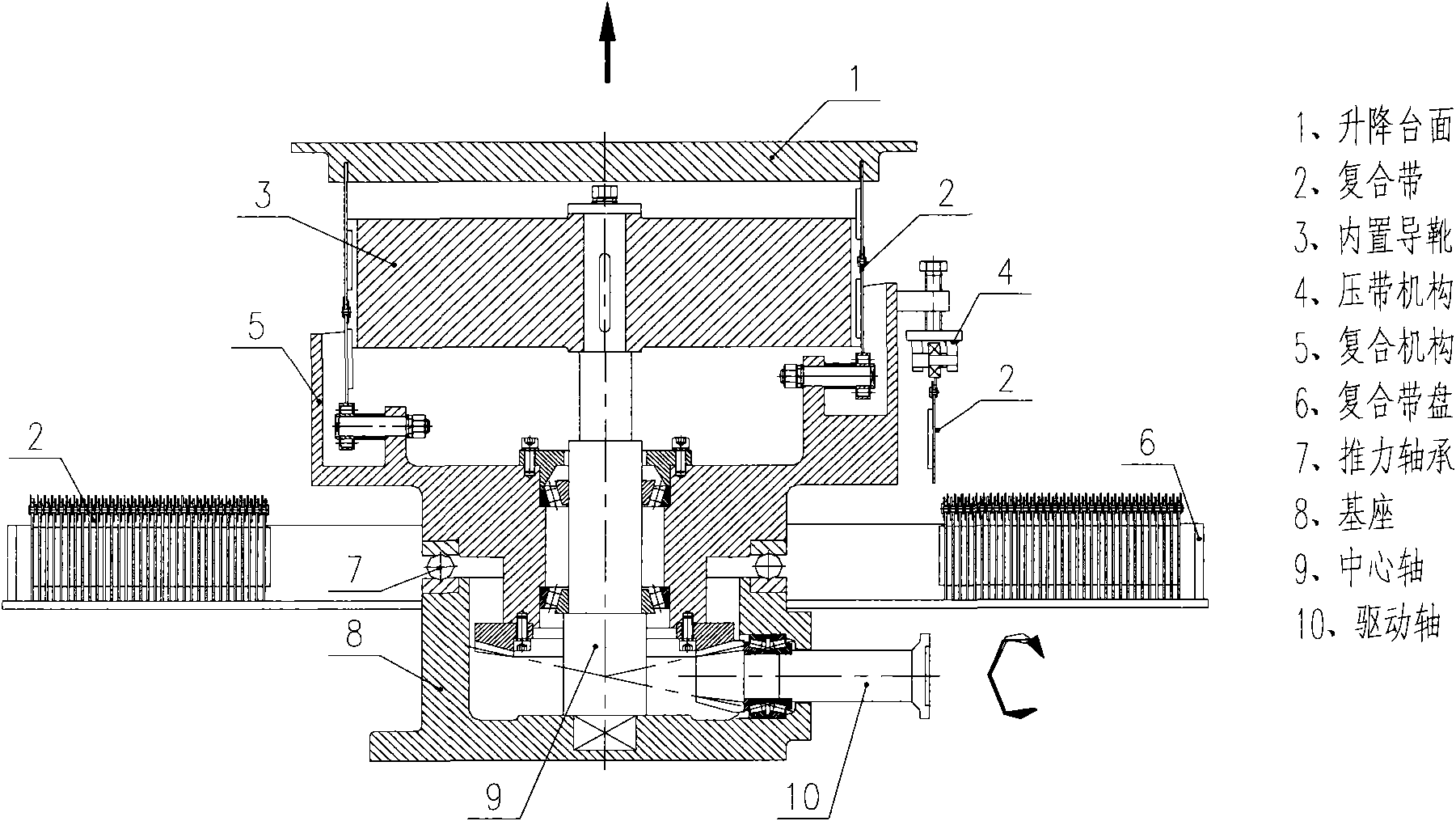

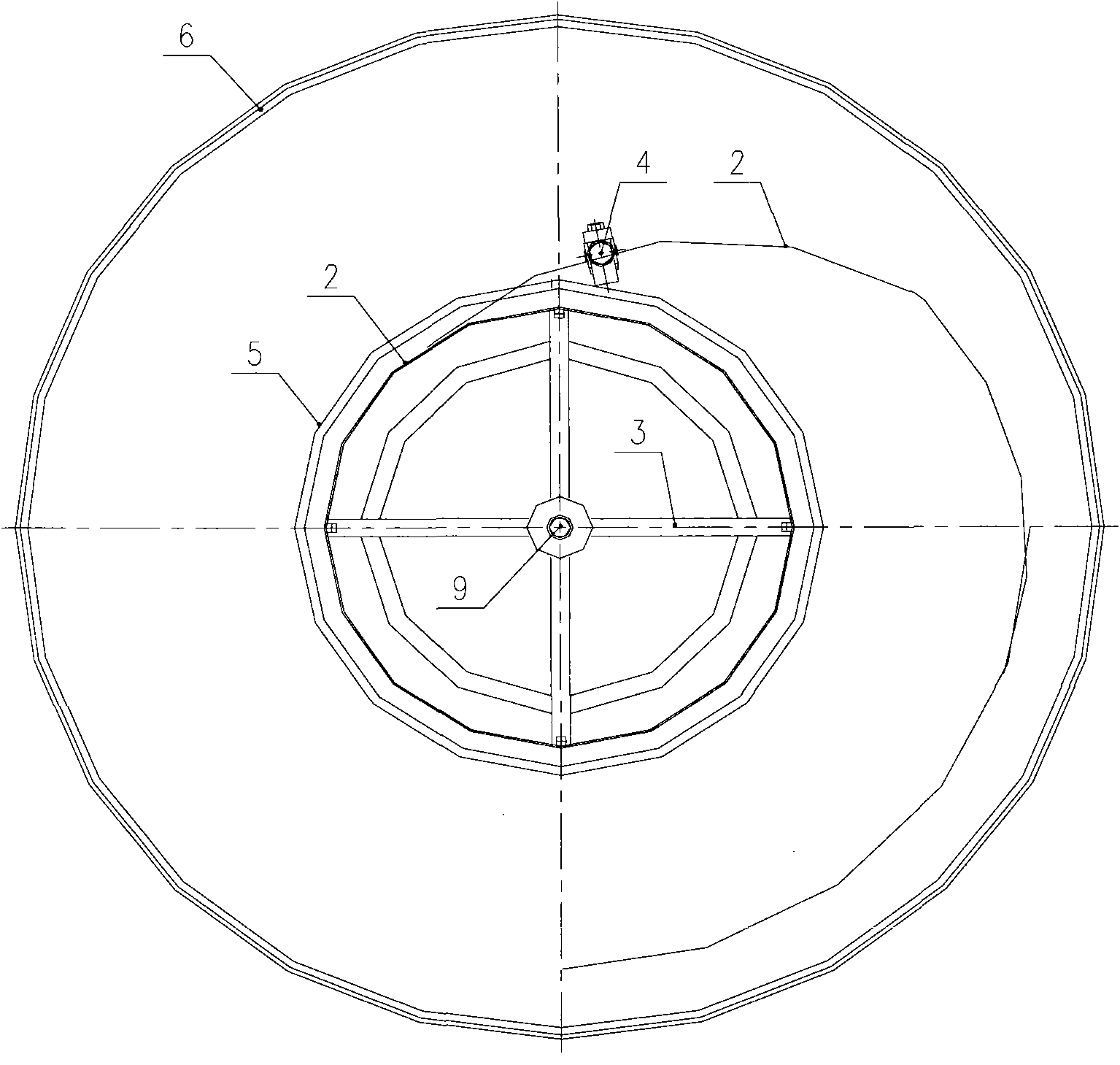

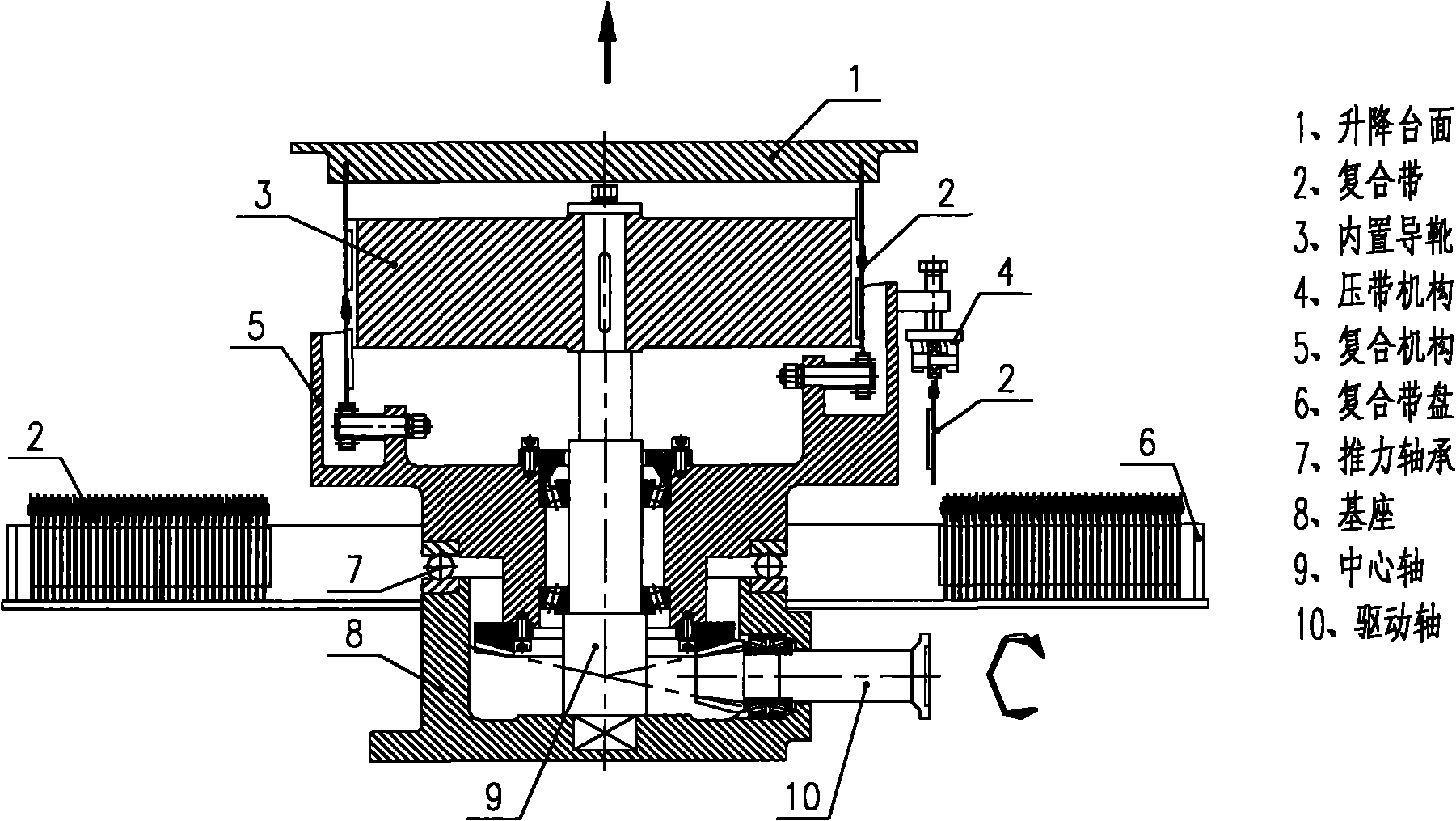

[0015] The following will be described by taking a single liftable right-handed composite pipe as an example (the specific implementation of a single left-handed composite pipe that can be lifted is the same). figure 1 The cross-sectional view of a single liftable composite pipe is shown.

[0016] A single lifting composite pipe can be driven by external power (reducer output shaft, ground shaft, etc.) to drive the drive shaft 10 mounted on the base 8 to rotate clockwise, and drive the composite mechanism 5 mounted on the thrust bearing 7 to operate. Clockwise movement. The composite belt 2 is loaded by the bearing on the composite mechanism 5. When the composite mechanism 5 moves clockwise, the built-in guide shoe 3 and the base 8 are fixed by the central shaft 9 and cannot rotate. Therefore, the guide block on the composite belt 2 can only Moving upward along the built-in guide shoe 3, the composite tape 2 is continuously output from the composite tape reel 6, and is accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com