Rude ore mining method for ion type RE ore

An ionic rare earth ore, mining method technology, applied in ground mining, earthwork drilling, underground mining and other directions, can solve problems such as uneven permeability coefficient, excessive liquid injection, too fast, easy to cause landslides, etc., and achieve labor costs. And the effect of reducing the amount of raw materials, less excavation, and increasing daily output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

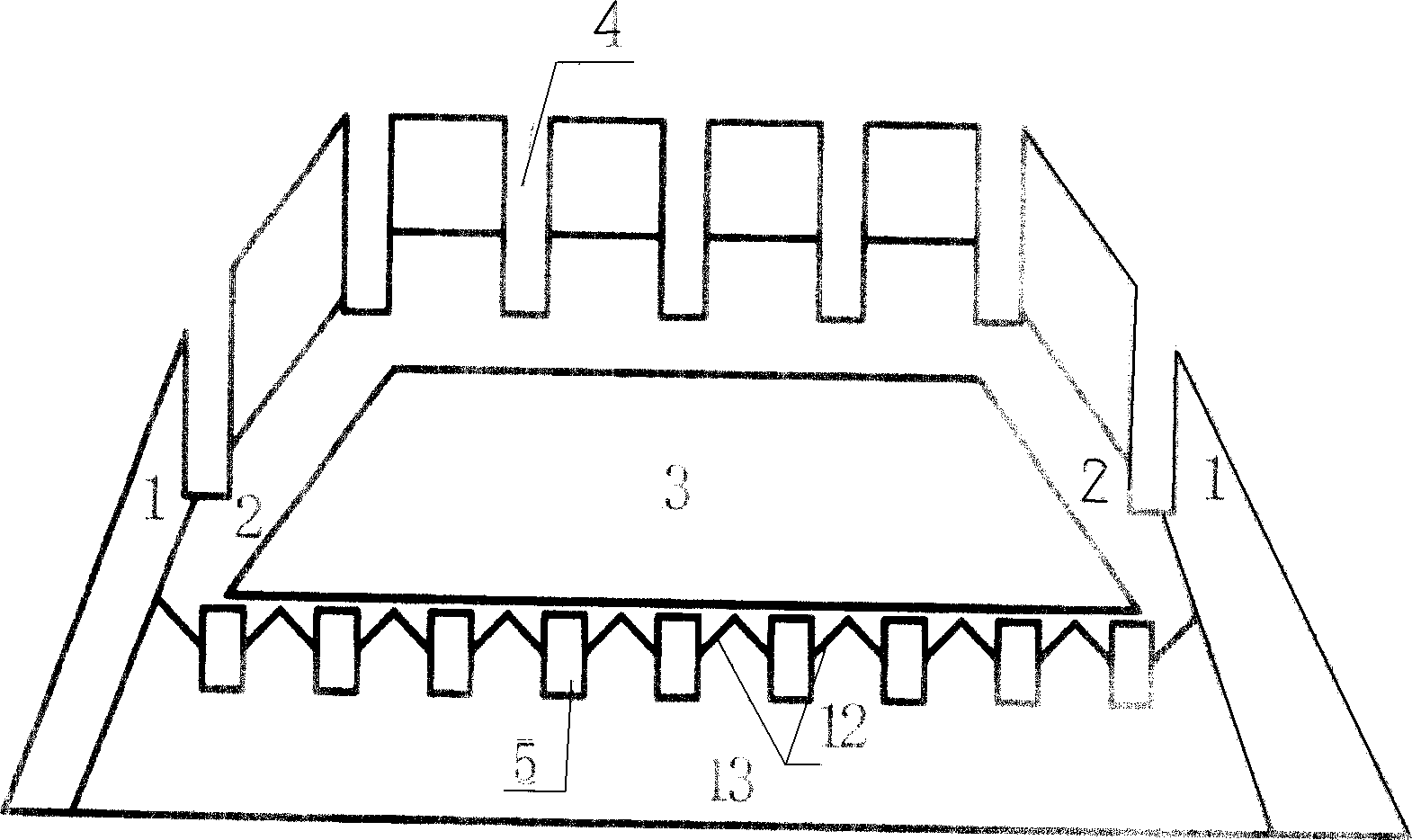

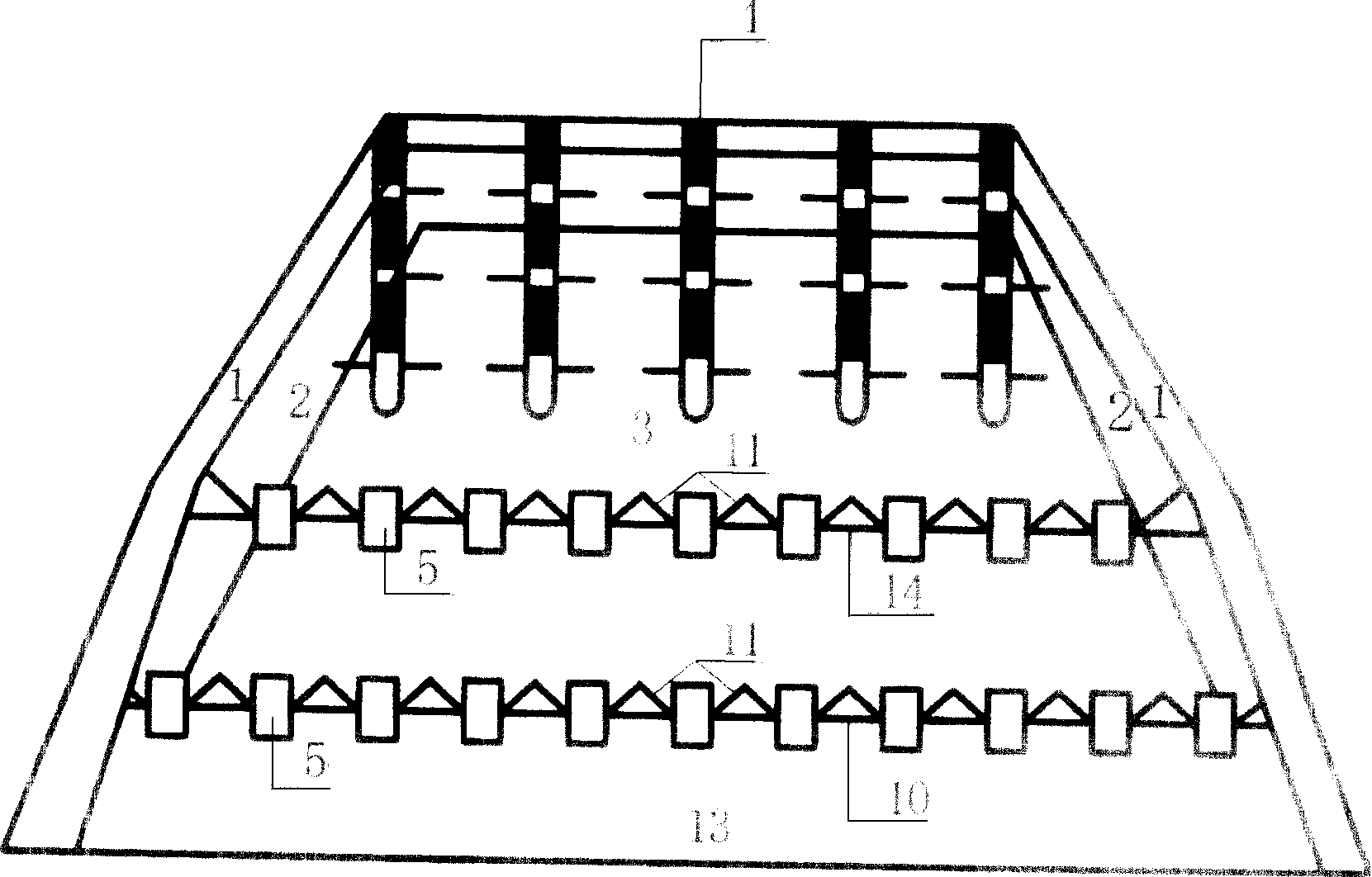

[0019] The present invention will be further described below in conjunction with the accompanying drawings. exist figure 2 Among them, this setting is mainly composed of a liquid injection hole 4, a tunnel 5, an anti-seepage layer 10, and a V-shaped drainage hole 11.

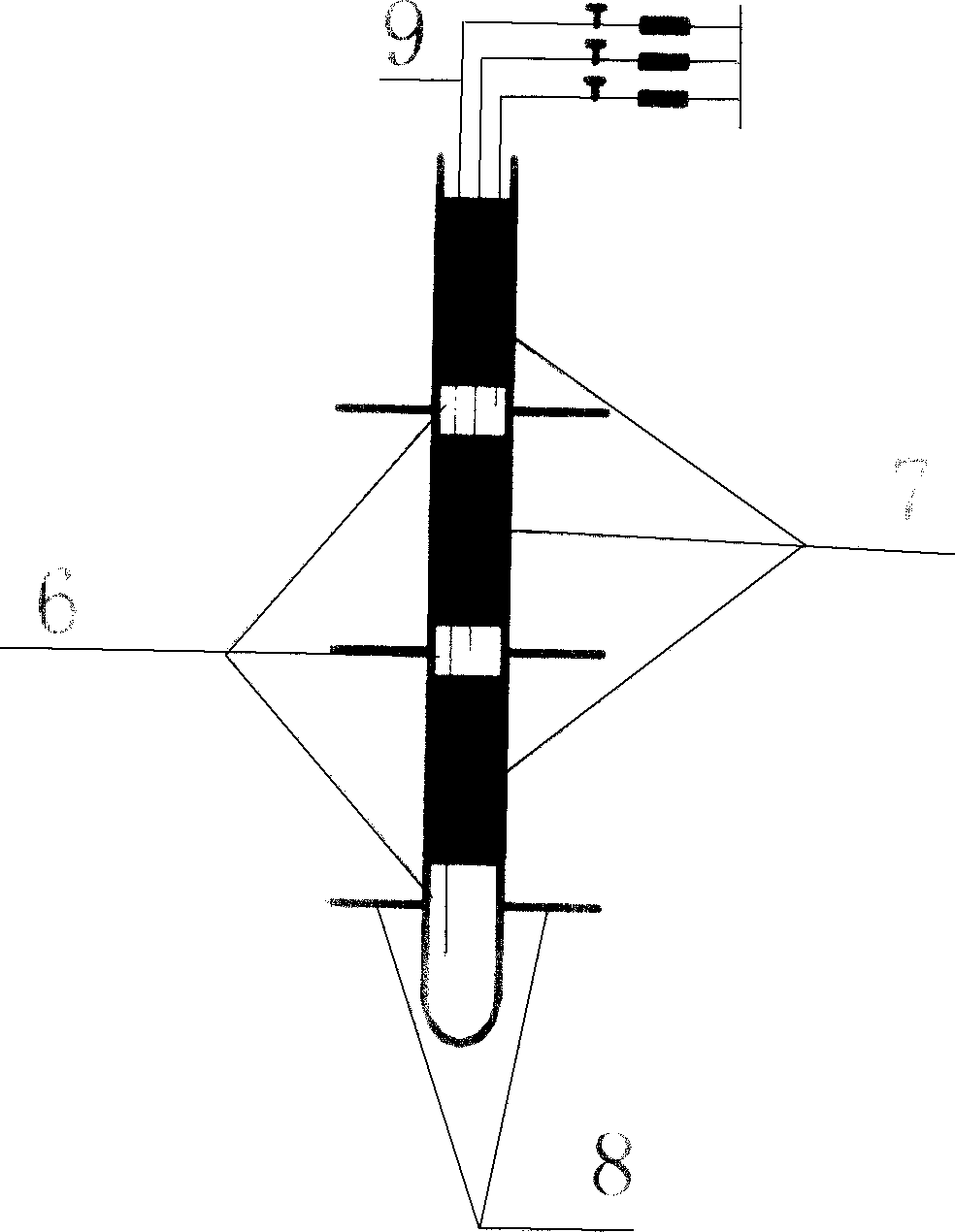

[0020] The distribution of liquid injection holes 4 is set according to the distribution of the ore seam plane, according to the permeability of the soil layer every 2-10m 2 Set a hole, where the permeability is high, take a large value, and where the permeability is small, take a small value. The diameter of the liquid injection hole 4 is about 0.1m, and the depth is from the surface soil layer 1 to the bottom of the ore layer, and the rare earth grade of the rare earth layer is about 0.3‰. From the bottom of the hole to the top, leave about 1m of unblocked liquid injection holes 6 every 2m. Embed the liquid injection pipe 9, wherein the liquid injection pipe 9 in the liquid injection hole 6 that is not blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com