Pipe-jacking installation method of bypass pipeline

An installation method and pipeline technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of large restrictions and high construction costs, and achieve safety protection, low construction costs, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

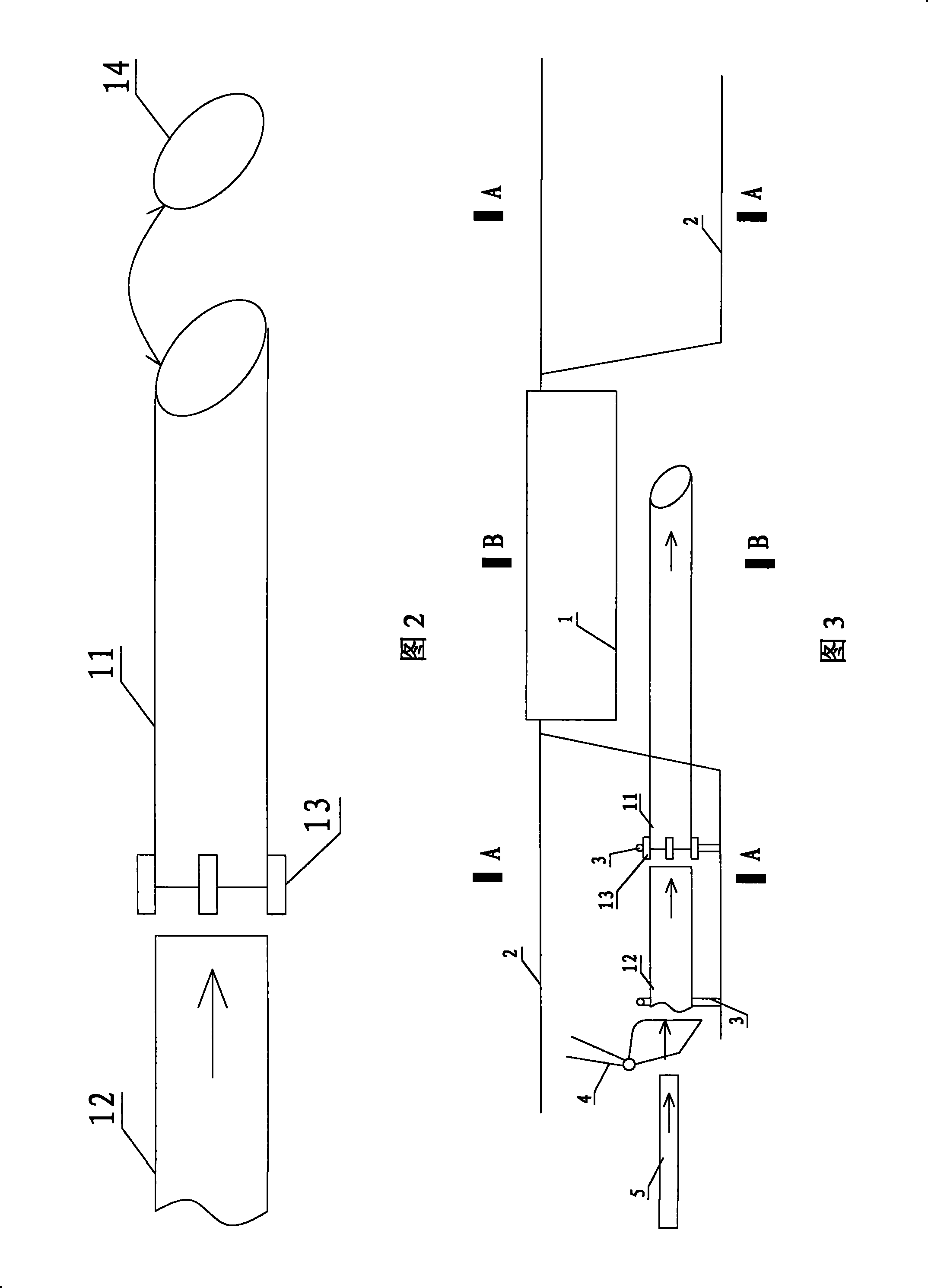

[0022] A pipe jacking installation method for passing pipelines, the engineering pipeline 5 to be installed has a diameter of 300 mm, and is carried out in sequence as follows:

[0023] Pipeline setting out→excavating guide trench→making casing→topping front casing→connecting casing→topping rear casing→putting through engineering pipeline and installing, the specific steps are:

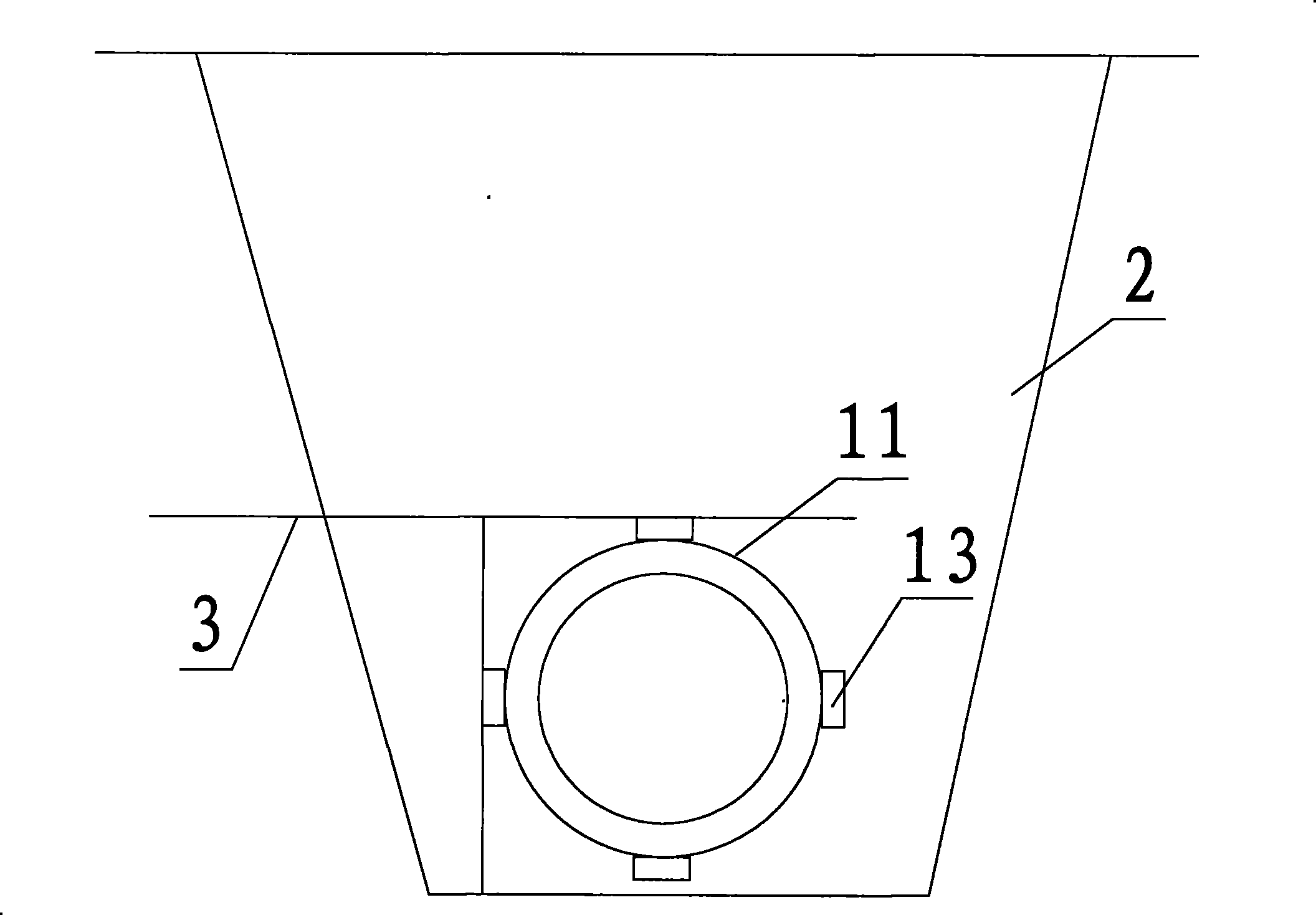

[0024] When excavating the guide ditch 2, excavate the guide ditch 2 on both sides of the obstacle 1 to be crossed, and fix the limit pile 3 in the guide ditch 2.

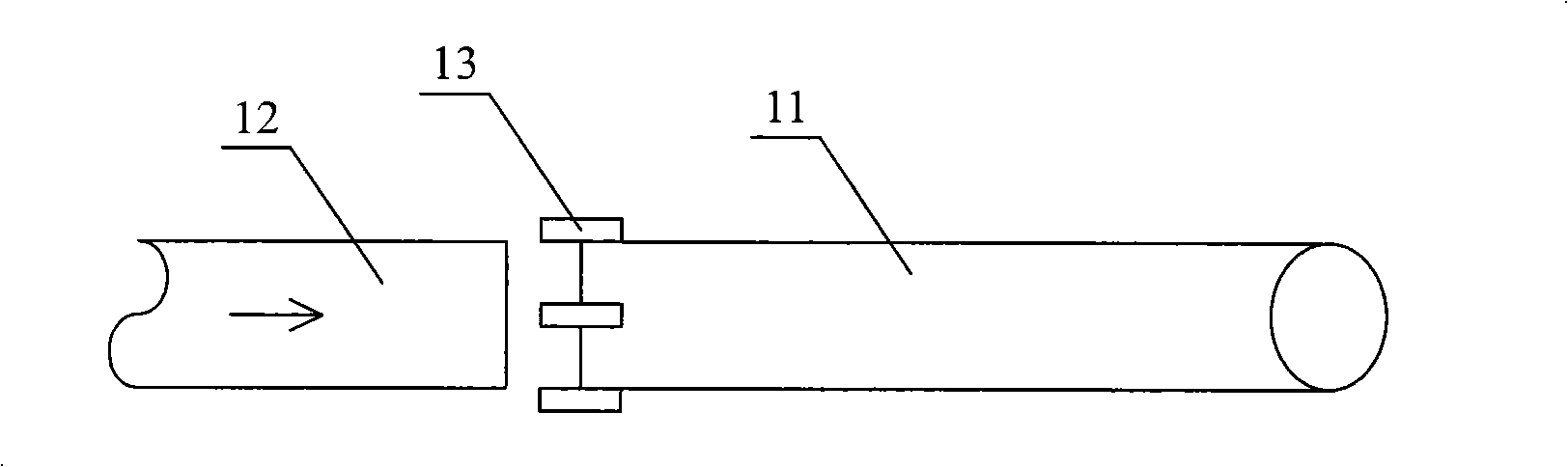

[0025] When making the casing, the casing such as figure 1 As shown, the inner diameter of the casing is 1 / 5 to 1 / 3 larger than the diameter of the engineering pipeline 5 to be penetrated, which is 400 mm. Uniform welding on the outer wall fixes 4 rectangular steel plates with a length of 100mm×width 50mm×thickness 20mm as the limiting plate 13, and half of the length of the limiting plate 13, that is, the 50mm part is welded on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com