Excavation tool

一种工具、刀片的技术,应用在挖掘工具领域,能够解决挖掘性能易受损、挖掘效率下降、工具寿命缩短等问题,达到抑制挖掘孔径缩小、降低挖掘费用、实现工具寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

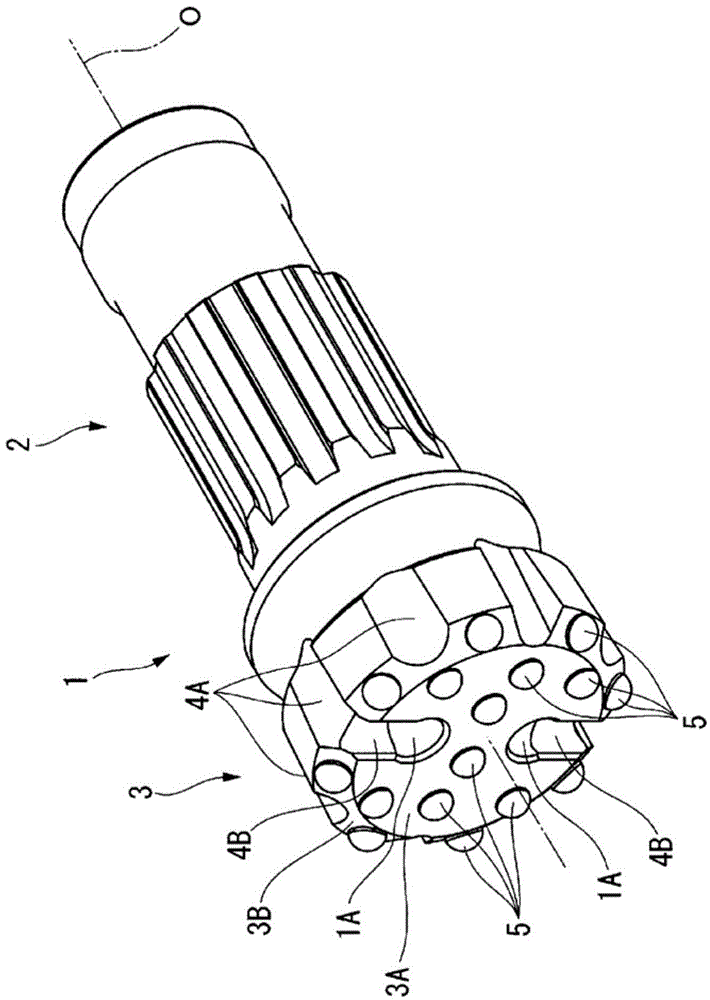

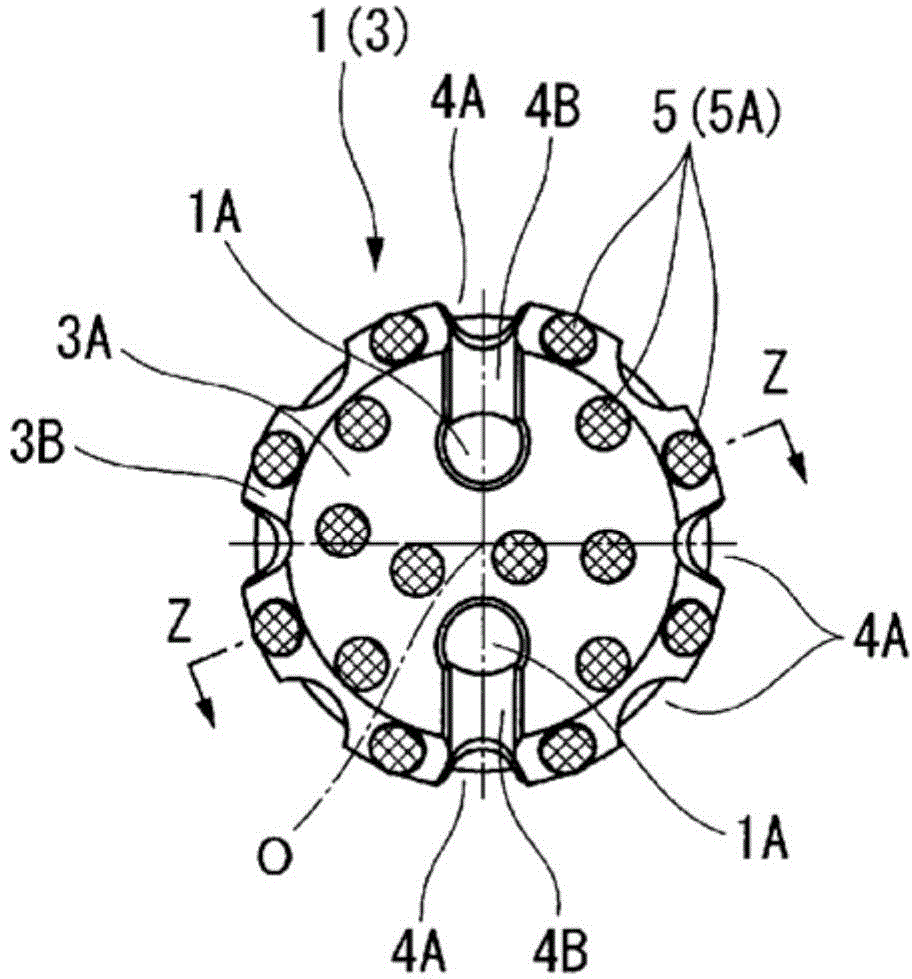

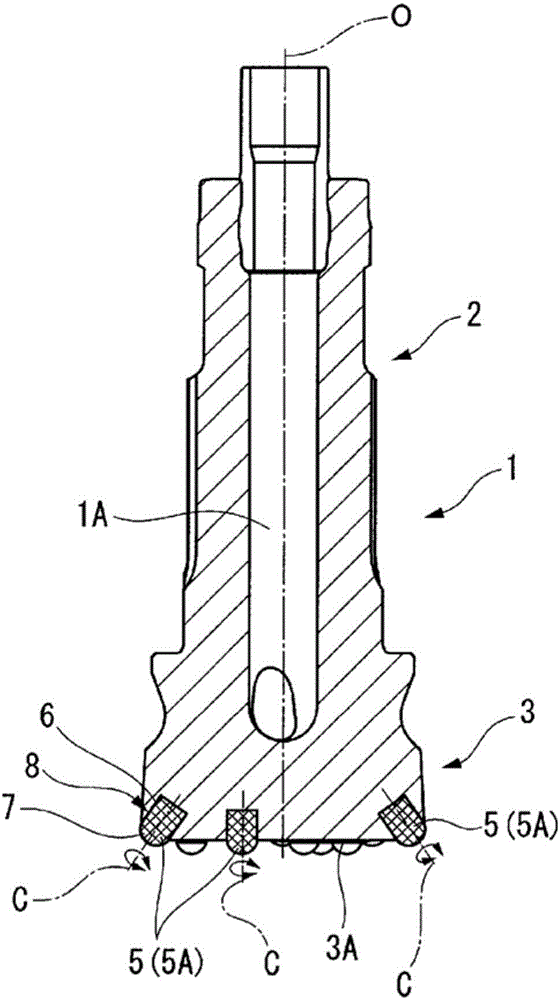

[0071] Figure 1 to Figure 5B It is a figure which respectively shows 1st - 4th embodiment of this invention. In these embodiments, the tool body 1 is formed of steel or the like, such as figure 1 As shown, it is the top part ( figure 1 Middle is the left part. Figure 2A to Figure 5B The lower side part in each B figure) is a large diameter and as it moves toward the rear end side (in figure 1 Middle is the right side. Figure 2A to Figure 5B Each B figure is the upper side), and the outer diameter gradually decreases in a substantially multi-stage cylindrical shape centered on the axis O.

[0072] The rear end portion of the tool body 1 is a shank 2 . The shank 2 is attached to an unillustrated down-the-hole hammer, whereby the tool body 1 receives an impact force from the down-the-hole hammer toward the tip side in the axis O direction. Furthermore, an excavating device is connected to the rear end of the down-the-hole hammer via an excavating rod not shown, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com