Method for presetting roadways by section moulds

A technology of roadway and excavation method, which is applied to mining equipment, earthwork drilling, filling materials, etc., and can solve problems such as increasing the cost of excavation, reducing the stability of filling bodies, and the safety of the mining roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

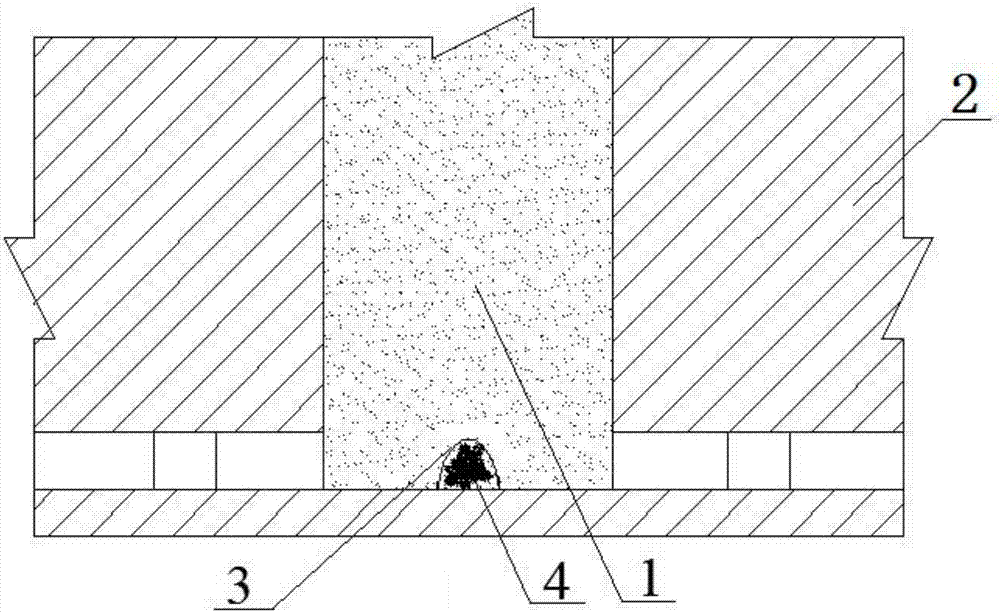

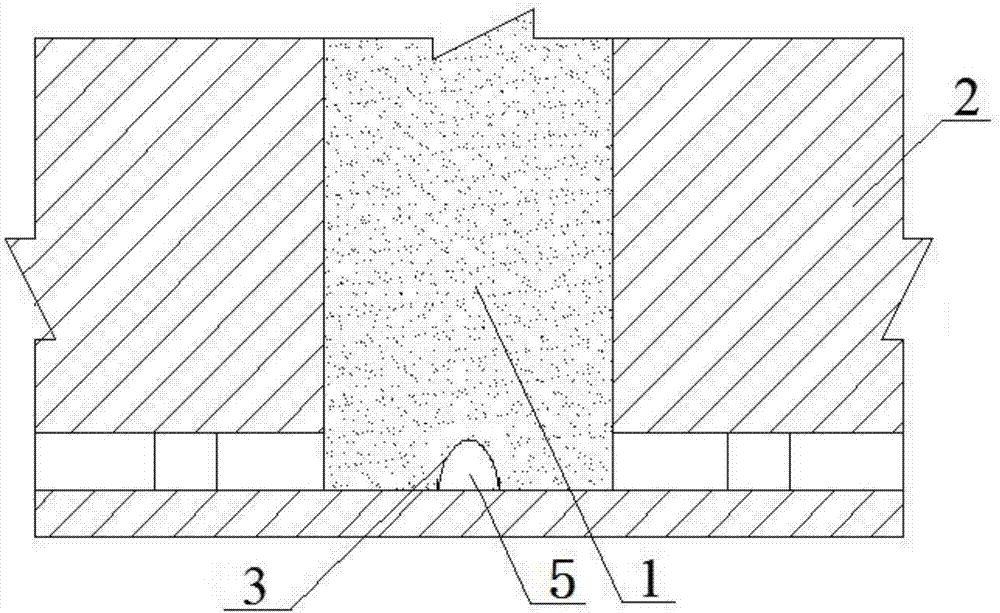

[0018] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0019] A method for presetting tunnels by molds. In one step, pre-lay an occupying mold at the bottom of the empty area of the stope, and then fill the occupying mold with non-cementitious slurry, and then start the one-step stope filling work after dehydration. After the filling of the one-step stope is completed, ordinary excavation methods can be used to form the exiting roadway of the two-step stope, which realizes the preset exiting roadway of the model.

[0020] In this embodiment, it is necessary to preset an arched mining tunnel with a cross-sectional specification of 2.8m×2.8m and a total length of 25m. The specific steps of the method for presetting the tunnel in the mold are as follows:

[0021] Step 1. Lay the space-occupying mold 3 at the preset position of the mine ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com