Sunken prefabricated inspection well and underground construction method thereof

A construction method and inspection well technology, which is applied to caissons, artificial islands, water conservancy projects, etc., to achieve the effects of saving excavation costs, simple construction, and reducing traffic impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

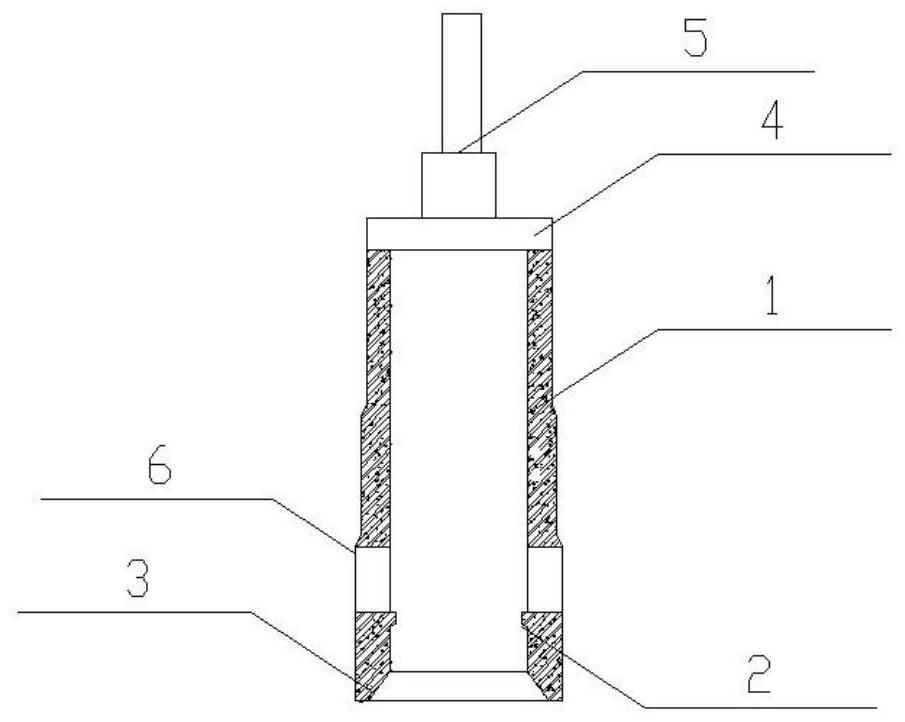

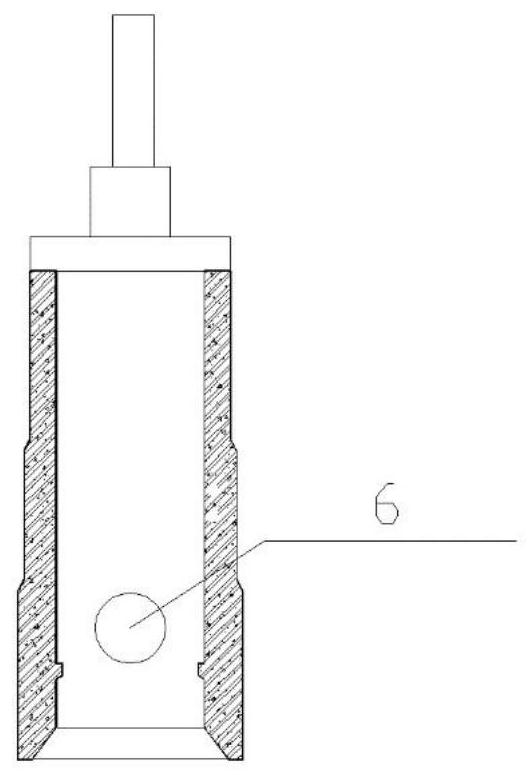

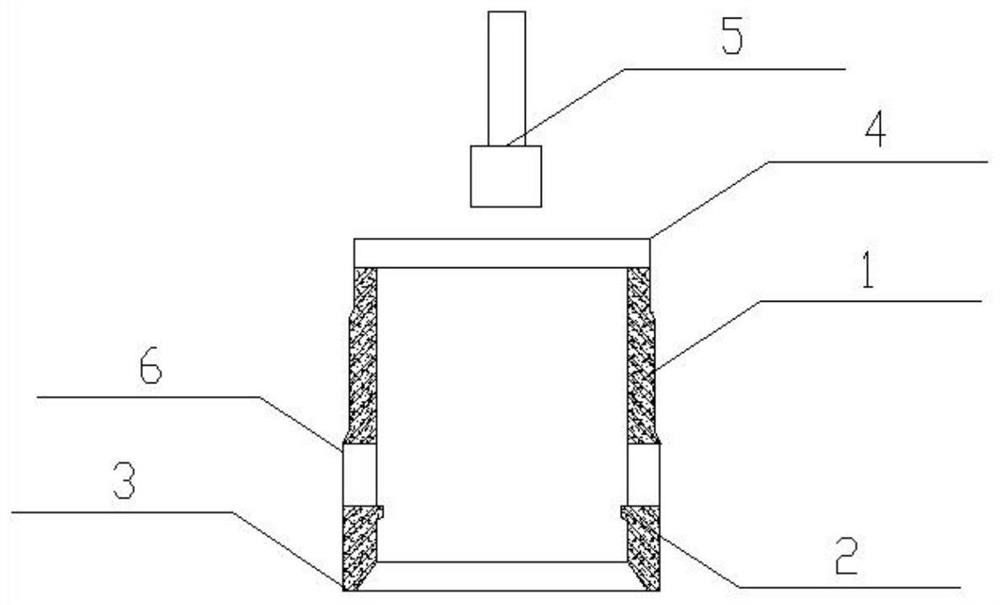

[0029] A sinking prefabricated inspection well, including a top plate, a bottom plate, and a valve well shaft 1, wherein the top plate and the bottom plate are respectively fixed and sealed on the end faces of the two axial openings of the valve well shaft; An annular blade foot 3 is provided, and a plurality of holes 6 are radially opened on the lower part of the valve well shaft; radially extending corbels 2 are integrally formed on the inner wall of the valve well below the holes.

[0030] Moreover, the circumferential outer wall of the valve well shaft has a stepped structure, and the diameter of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com