Longwall mining N00 construction method

A longwall and mining process technology, applied in ground mining, mining equipment, earth drilling and mining, etc., can solve problems such as low work efficiency and waste of resources, and achieve the effect of improving efficiency and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

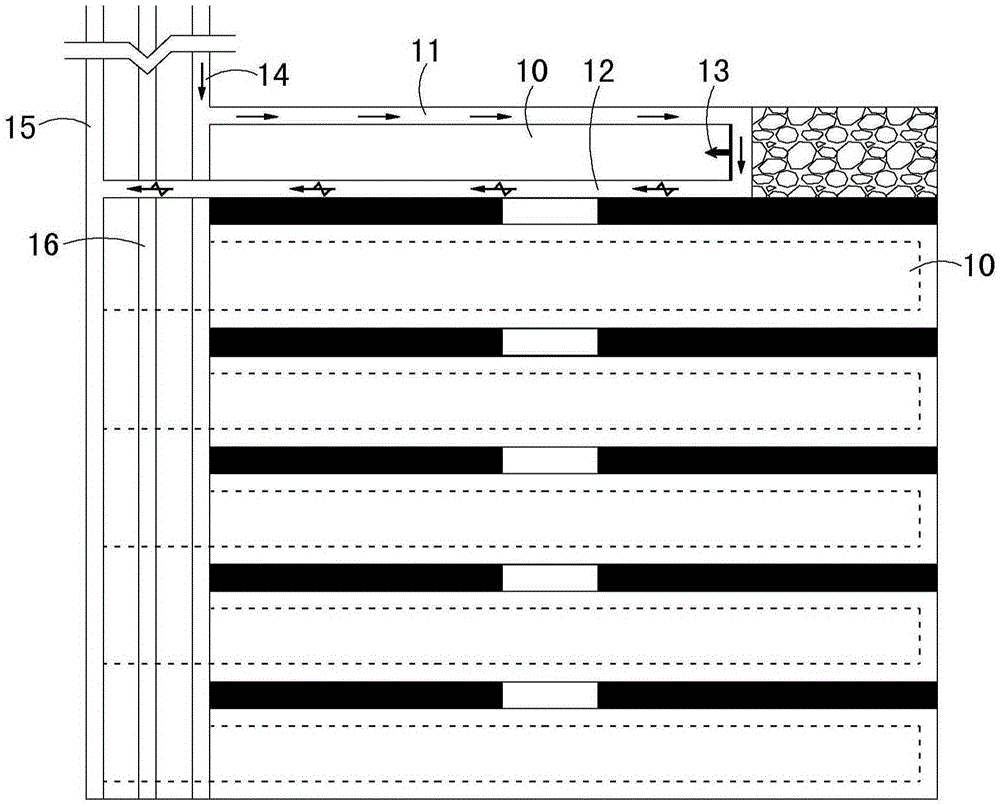

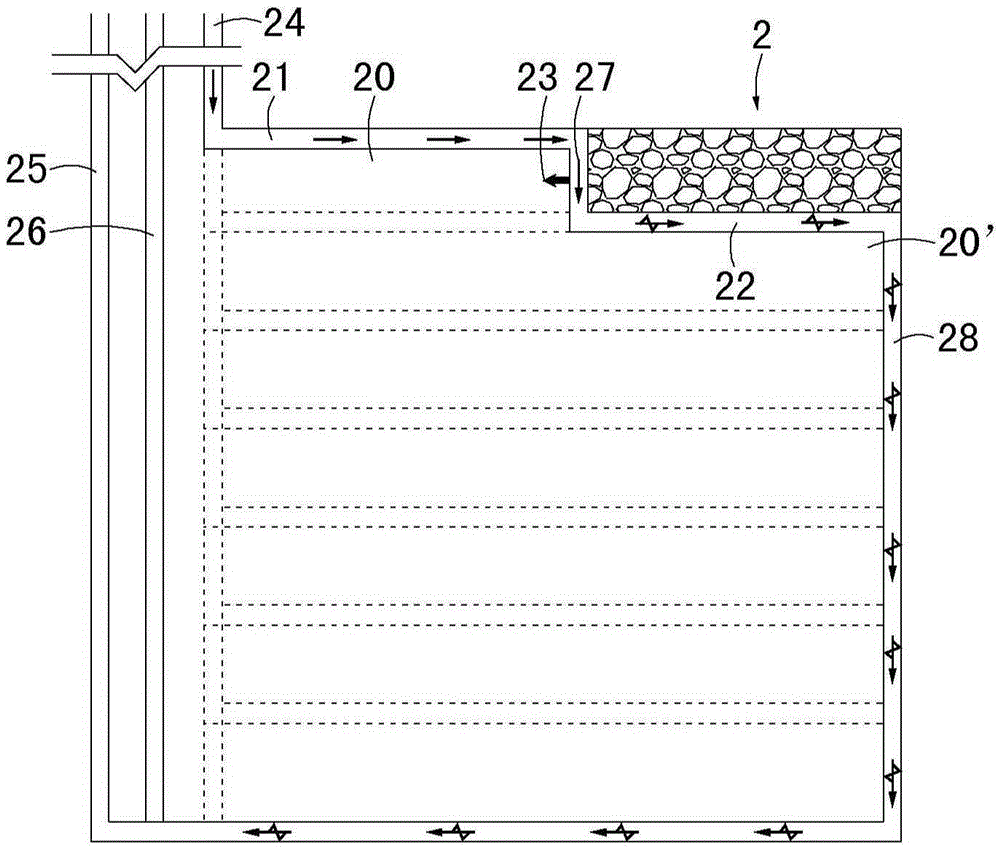

[0020] Longwall mining N00 method is a new type of coal mining method, which is characterized in that it does not need to dig up and down troughs when mining at the working face, and does not need to leave coal pillars, and can ensure the ventilation of the entire panel. The structure of a specific embodiment will be described below.

[0021] Longwall mining N00 construction method of the present invention in a specific application such as figure 2 As shown, including the entire panel 2, a return air downhill passage 25 and a track downhill passage 26 are dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com