Composite roof thin seam fully-mechanized coal mining face gob-side entry retaining method

A technology of fully mechanized mining face and composite roof, applied in mining equipment, earthwork drilling, filling and other directions, can solve the problems of low wall strength, difficult to bear the pressure of lagging working face, not suitable for large-scale promotion, etc. The effect of convenient retraction of struts and filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

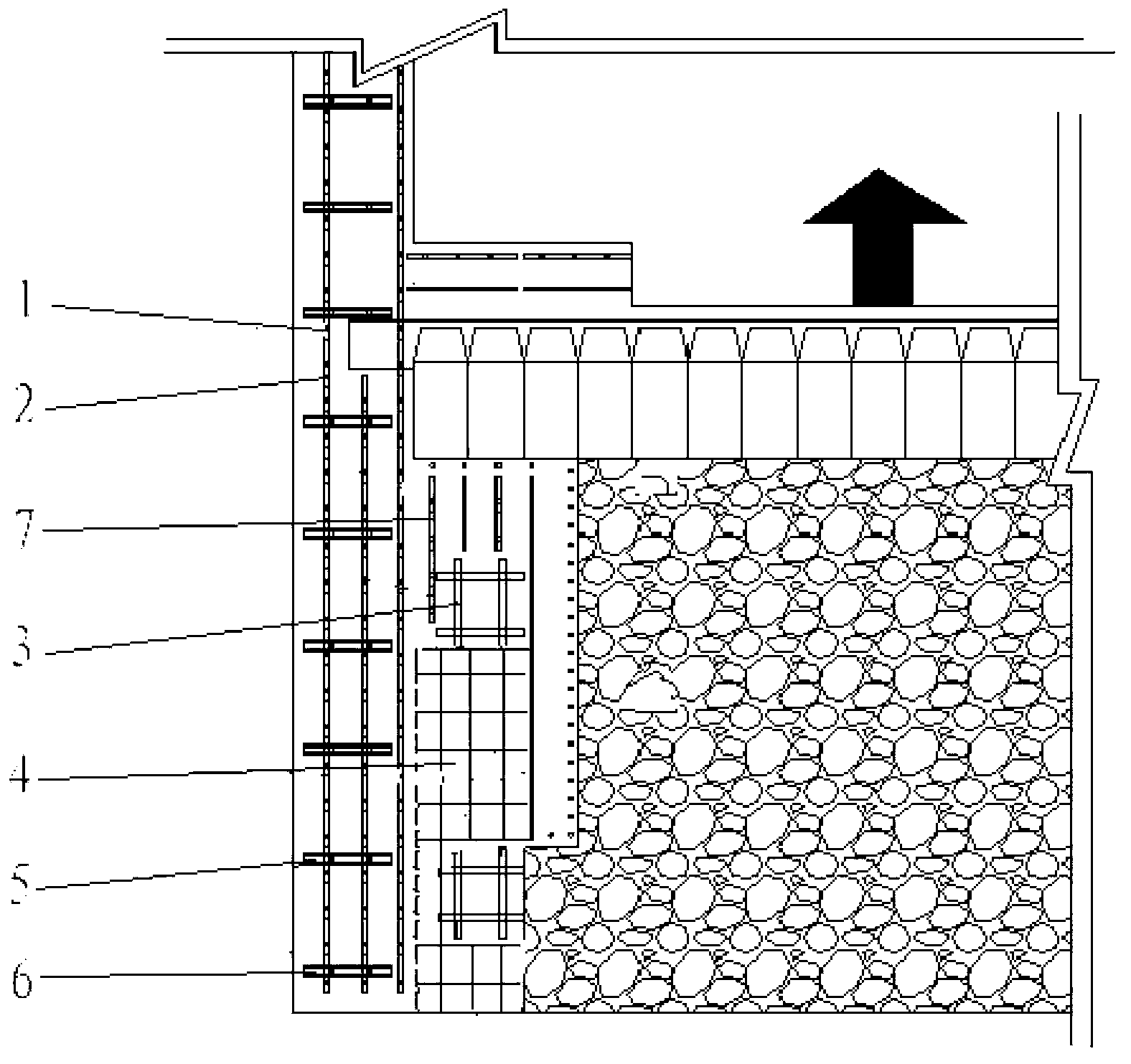

[0015] Attached below figure 1 The preferred embodiment of the gob-side entry retaining method of the composite roof thin coal seam fully mechanized mining face of the present invention will be described in detail.

[0016] In the process of retaining gob-side entry in the fully mechanized coal mining face with composite roof and thin coal seam, the anchor cable beam is added to strengthen the support after the diamond-shaped net is hung on the leading working face in the entry. The model of the anchor cable beam is φ15.24×5000mm, and its vertical Direction layout, 0.2m away from the old empty side, multiple anchor cables are set on the anchor cable beam, the anchor cable is inclined 5° to the side of the working face, and a 3.0m long 12# I-shaped steel beam is installed on both sides of the anchor cable beam , Two drill holes are set on each I-beam to pass through the anchor cable. The drill holes are set at a distance of 1.0m from both ends, and the diameter of the drill hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com