Novel circular tube slitting mill

A rolling cutting machine and pipe material technology, which is applied in the direction of pipe shearing devices, shearing devices, and attachments of shearing machines, etc., can solve the difficulty in aligning the clamping center and rolling cutting center of the clamping device, and the difficulty in controlling the separation time of the clutch , the length of the cantilever of the rotary hobbing mechanism, etc., to achieve the effects of improving stability and centering reliability, accurate knife retraction time, and reducing the length of the cantilever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

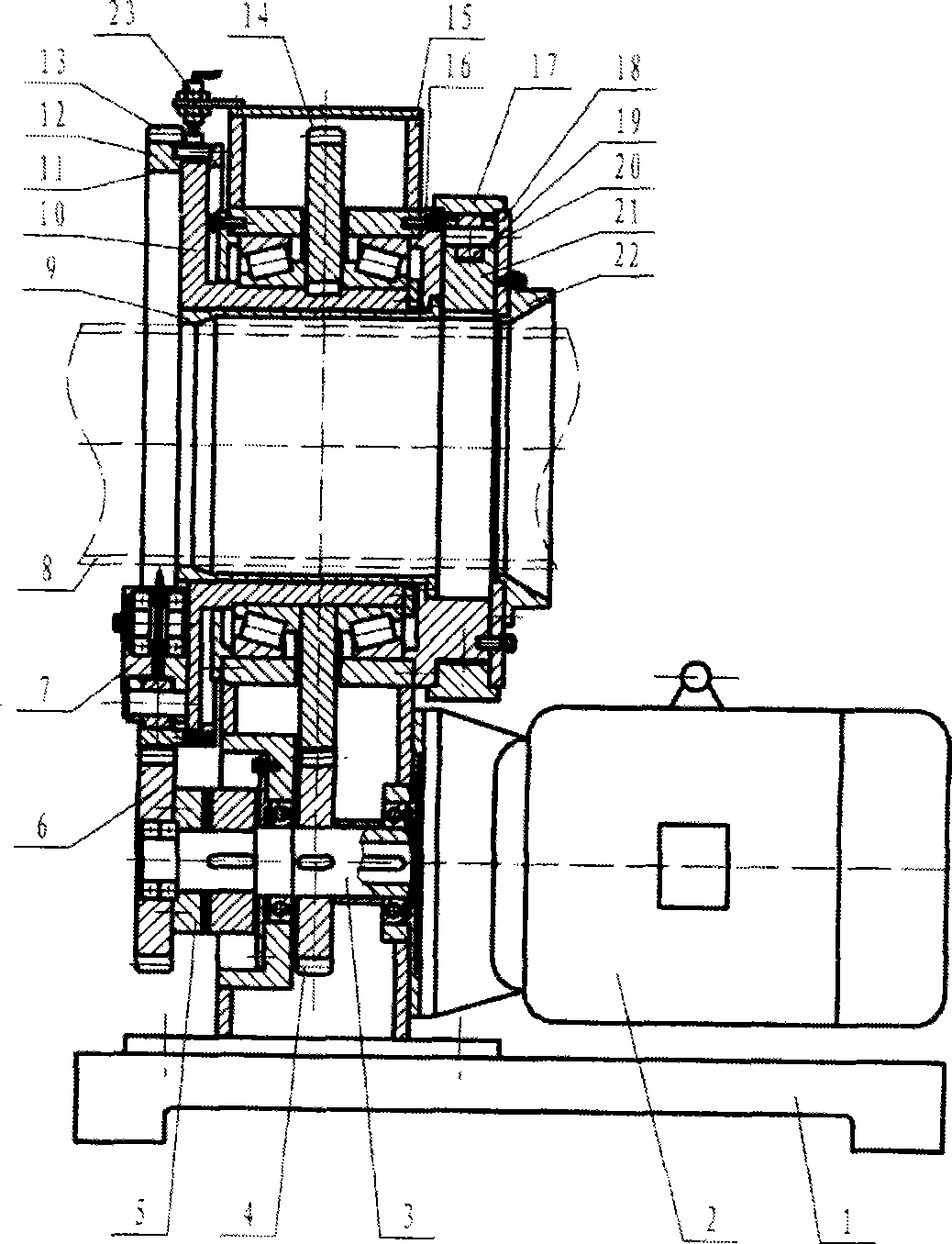

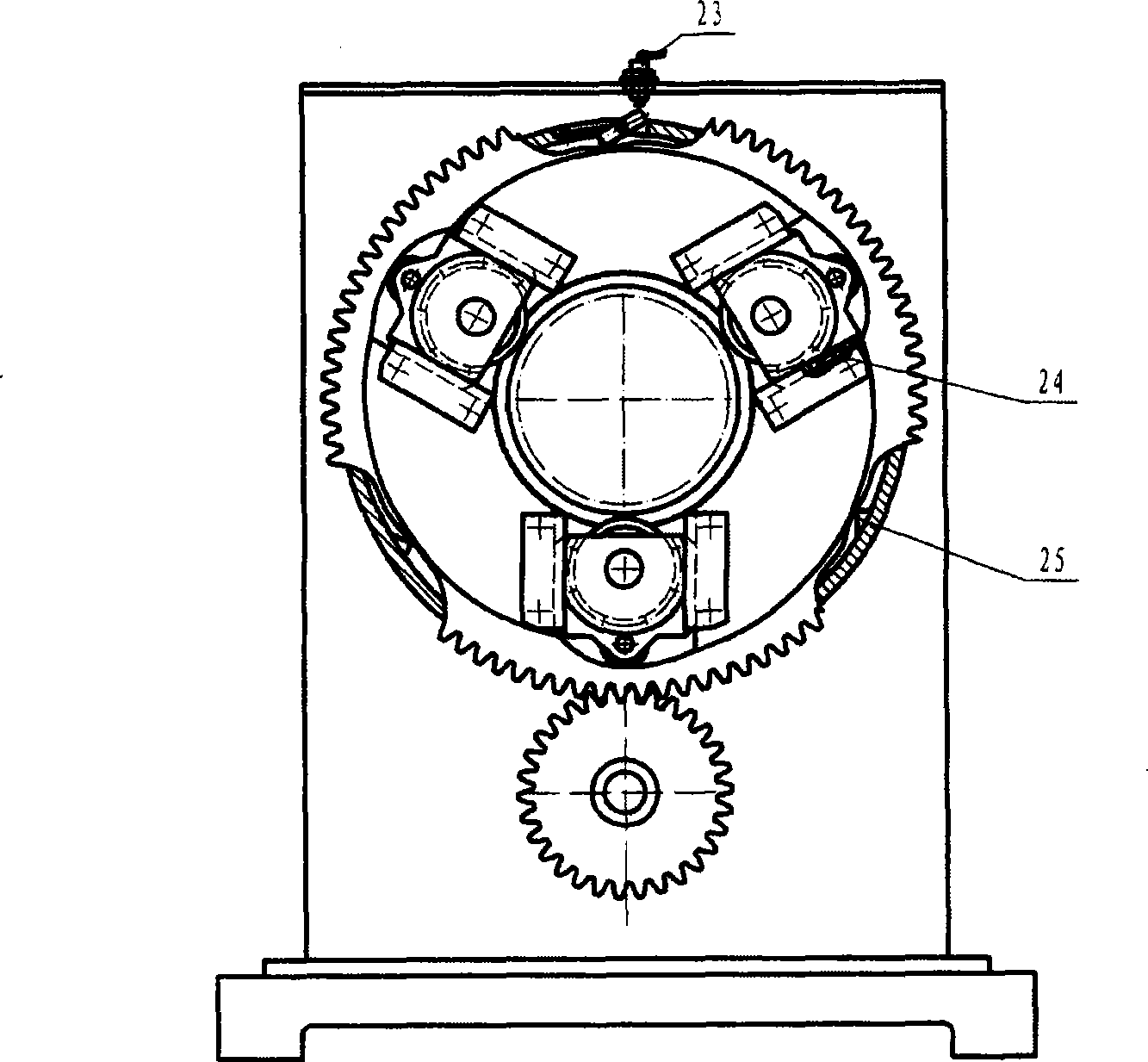

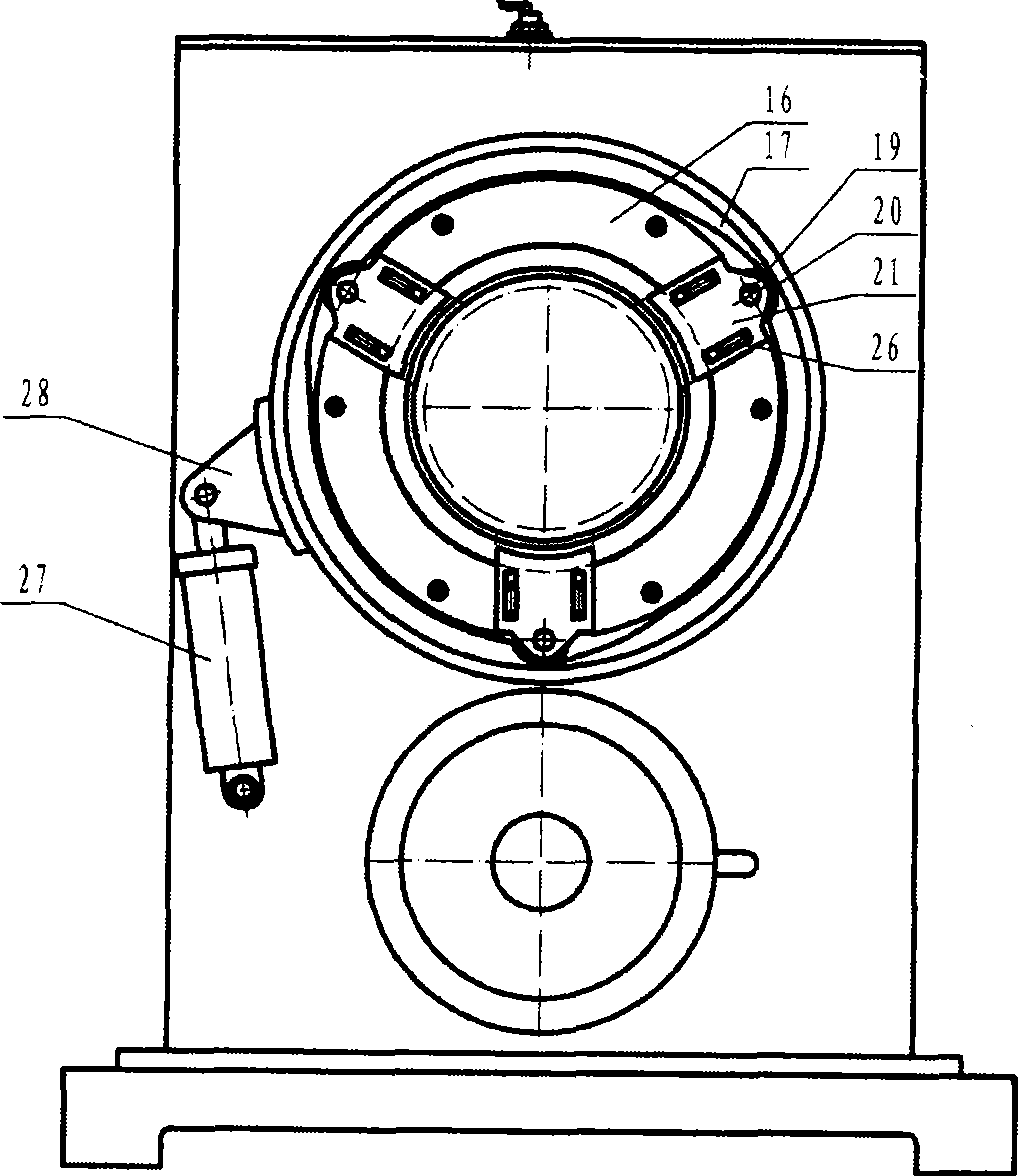

[0018] The present invention is described in detail below in conjunction with accompanying drawing embodiment:

[0019] Depend on figure 1 , figure 2 , image 3 The shown circular section pipe rolling cutting machine includes a frame 15 installed on the base 1, and a transmission shaft 3 is installed at the lower part of the frame 15; one end of the transmission shaft 3 is connected with the output shaft of the motor 2, reducing The transmission link is improved, the efficiency is improved, and the equipment is more compact. The transmission shaft 3 is provided with a clutch 5 and a transmission pinion 4 and a hobbing pinion 6 arranged on both sides; a relative frame 15 is installed in the inner hole of the upper part 15 of the frame through a bearing (not marked in the figure). Rotating disk shaft 10; fixedly installed transmission bull gear 14 on the disk shaft 10 between the bearings; and a rotating ring 12 installed on the disk outer ring of the disk shaft 10. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com