Large-span grotto excavation construction method

A construction method and cavern technology, which is applied in underground caverns, earthwork drilling, wellbore lining, etc., can solve the problems of long construction period, increased tunnel construction cost, and many construction materials, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

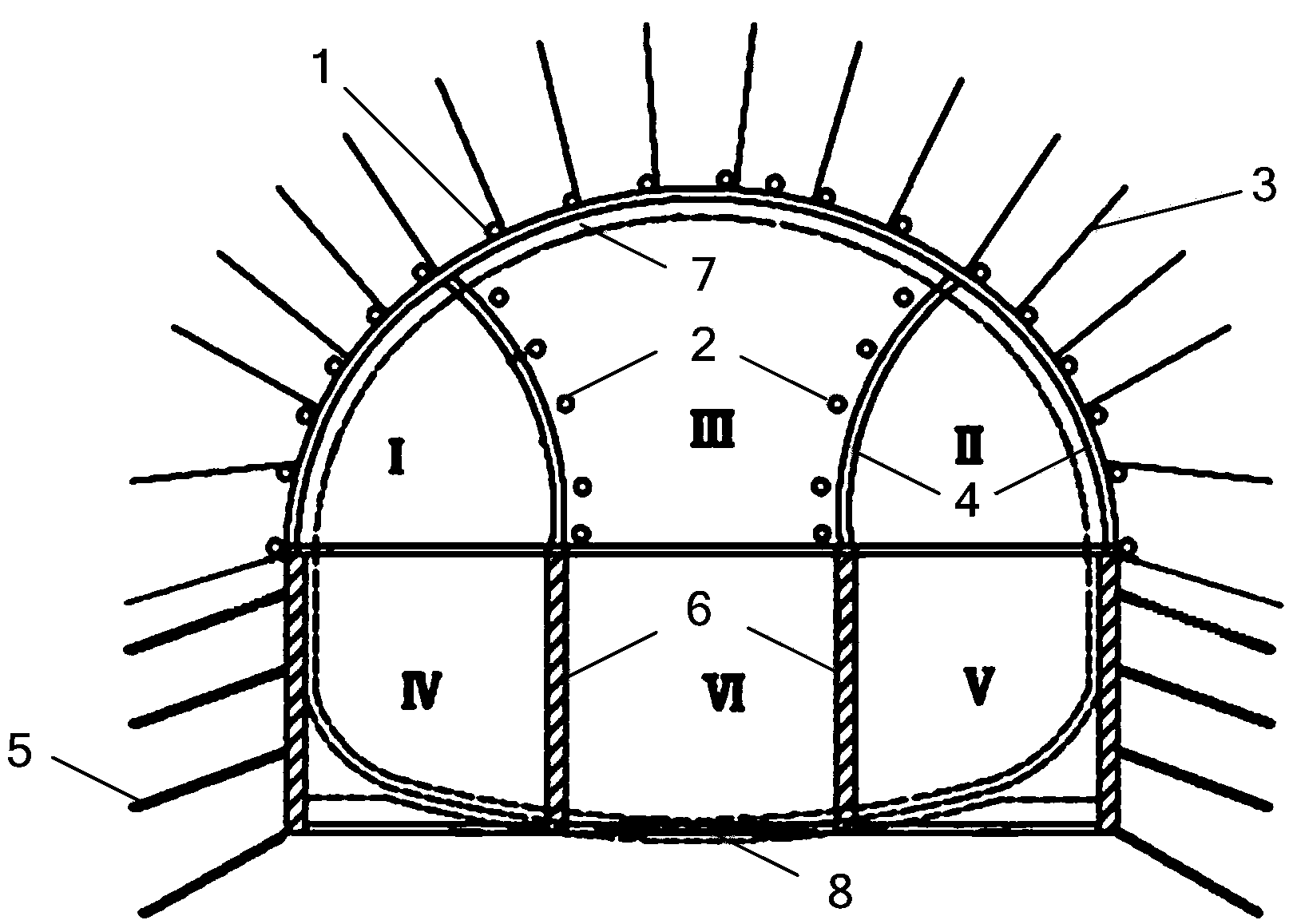

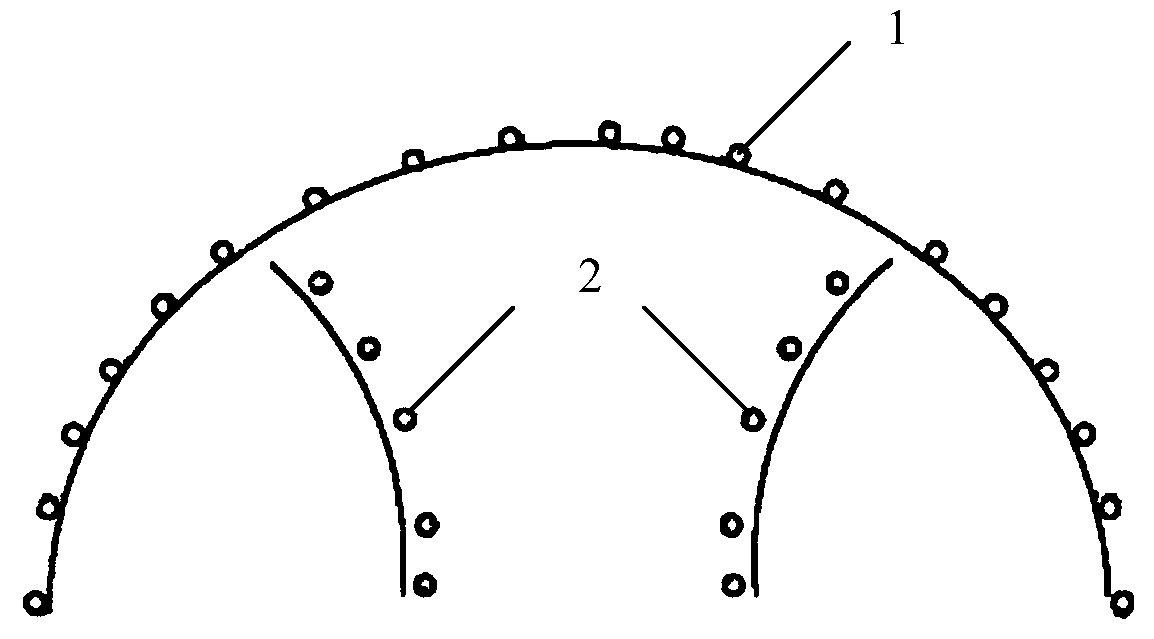

[0054] Such as figure 1 As shown, the excavation section of the cavern is composed of 6 parts, and the pilot tunnels I, II, III, IV, V, and VI are pilot pits excavated in order, and the large-span cavern excavation construction method of the present invention, include:

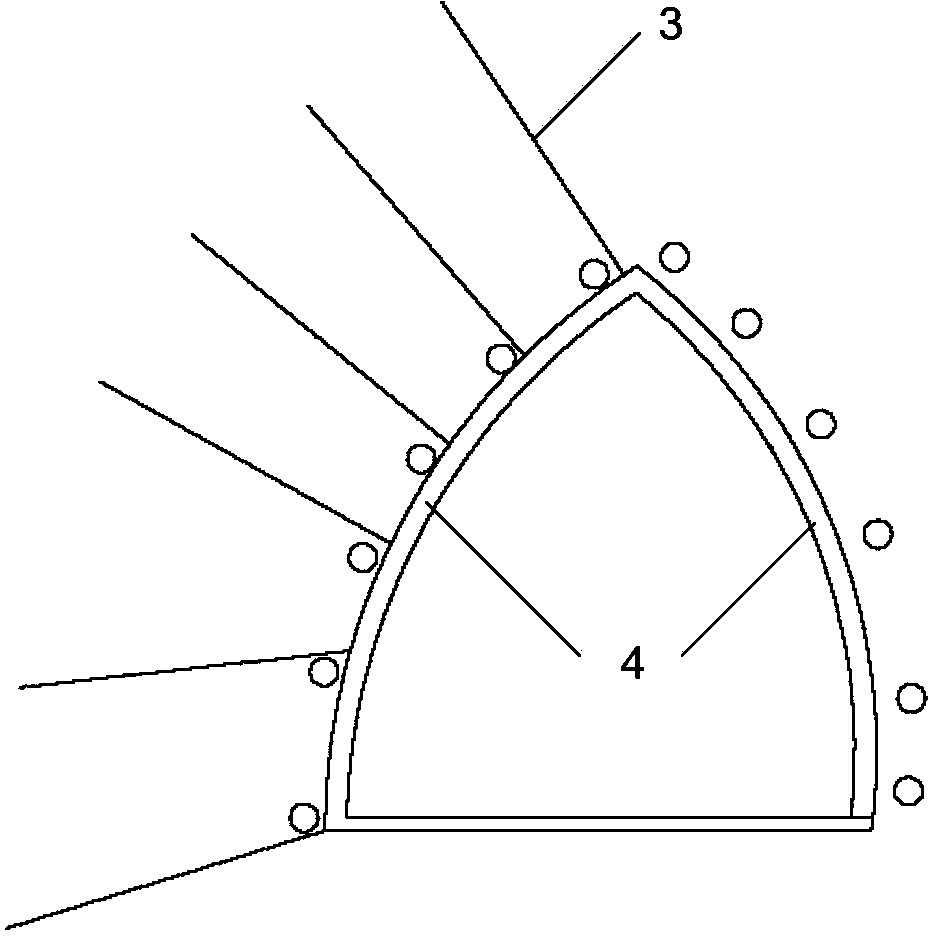

[0055] Step S1: first divide the left, right, and middle parts into three parts, and carry out initial support for the surrounding rock of each part of the cavern.

[0056] The initial support includes installing steel arches or grid steel frames 4 and steel mesh, laying advanced pipe sheds or advanced grouting cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com