Construction method for compound construction of large-scale underground space structure by holes, groove and piles

A technology of spatial structure and construction method, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as shortening the construction period and restrictions on the surrounding construction environment, so as to reduce construction risks, shorten the construction period, and reduce project costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

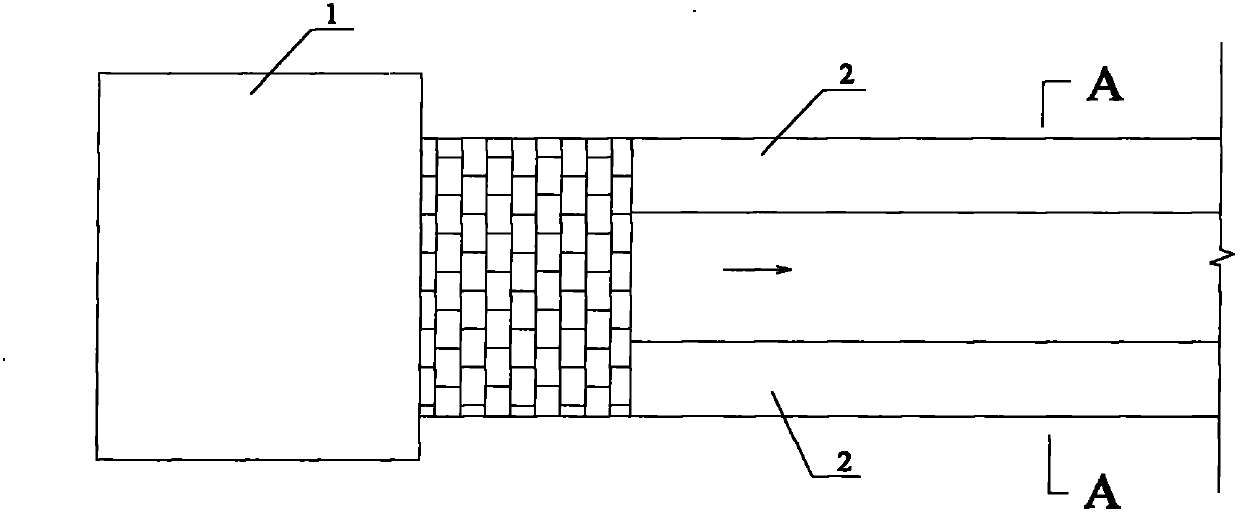

[0052] Embodiment 1 is to build an underground single-span arched structure on the basis of constructing a pilot tunnel using the shallow buried excavation method for the tunnel method, see Figure 1 to Figure 11 , the steps are as follows:

[0053] Step 1, excavating a construction shaft (1) at the planned start construction end.

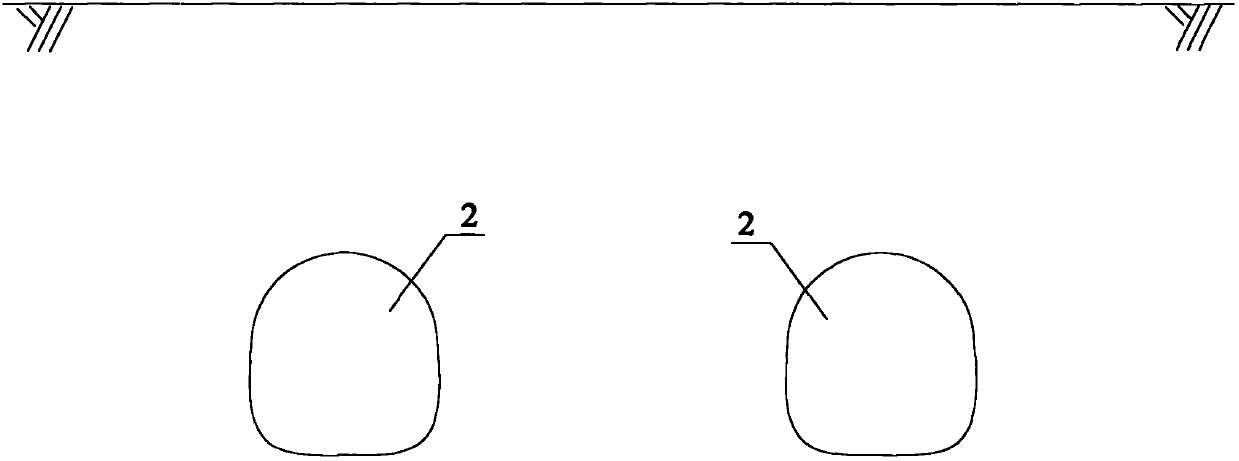

[0054] Step 2: In the construction shaft (1), two pilot tunnels (2) with a width of 5 meters and a height of 6 meters are constructed in advance by shallow burial and underground excavation in the extension direction of the planned underground space structure.

[0055] Step 3: In the completed pilot tunnel (2), remove the lower part of the lining to construct the support piles (3). The pile diameter of the support piles is 1.2 meters, and the distance between the piles is 2.8 meters.

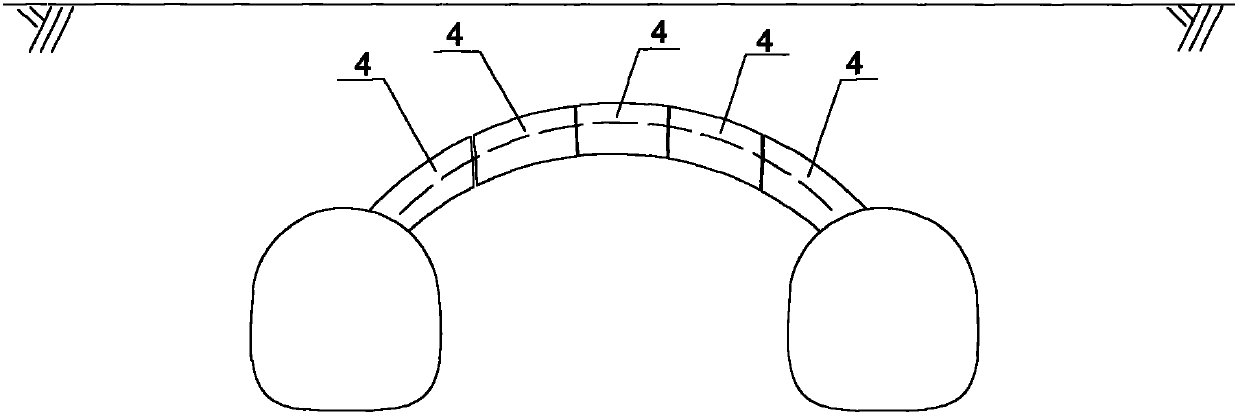

[0056] Step 4, in the construction shaft (1), the construction of the top groove (4) is carried out in the upper space between two adjacent pilot tunnels (2) by shall...

Embodiment 2

[0062] Embodiment 2 is to build an underground single-span arched structure on the basis of tunnel method using shield to build pilot tunnels, see Figure 12 to Figure 22 , the steps are as follows:

[0063] Step 1, excavating a construction shaft (1) at the planned start construction end.

[0064] Step 2: In the construction shaft (1), two shield tunnels (2) with a diameter of 6 meters are constructed in advance by using the shield method in the extension direction of the underground space structure to be constructed.

[0065] Step 3, in the construction shaft (1), the construction of the top groove (4) is carried out in the upper space between two adjacent shield tunnels (2) by shallow buried underground excavation method, and the long axis of the top groove (4) is It is 4.0 meters long and the short axis is 2.5 meters. It adopts a steel grid concrete structure and is an independent and stable structure; steel grids are reserved on the upper sides of the top groove (4) to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com