Mounting and constructing method for steel plate shear wall

A steel plate shear wall and construction method technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as local buckling and additional bending moments of columns, and achieve the effects of saving construction time, reducing construction difficulty, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The construction method of the steel plate shear wall of the present invention will be described in detail below with reference to the accompanying drawings.

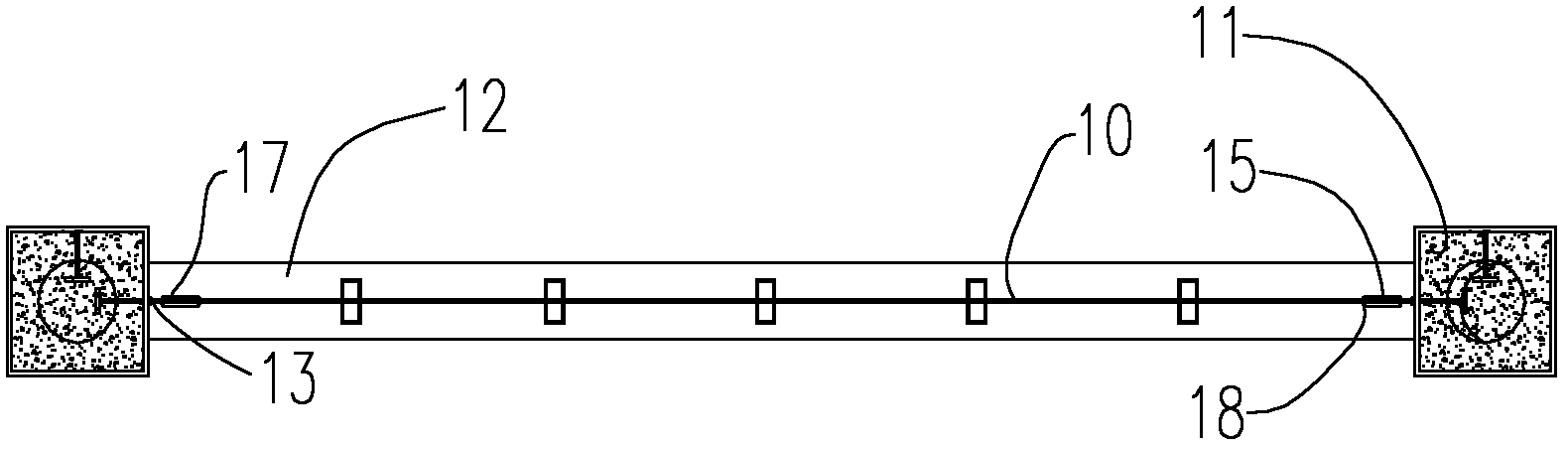

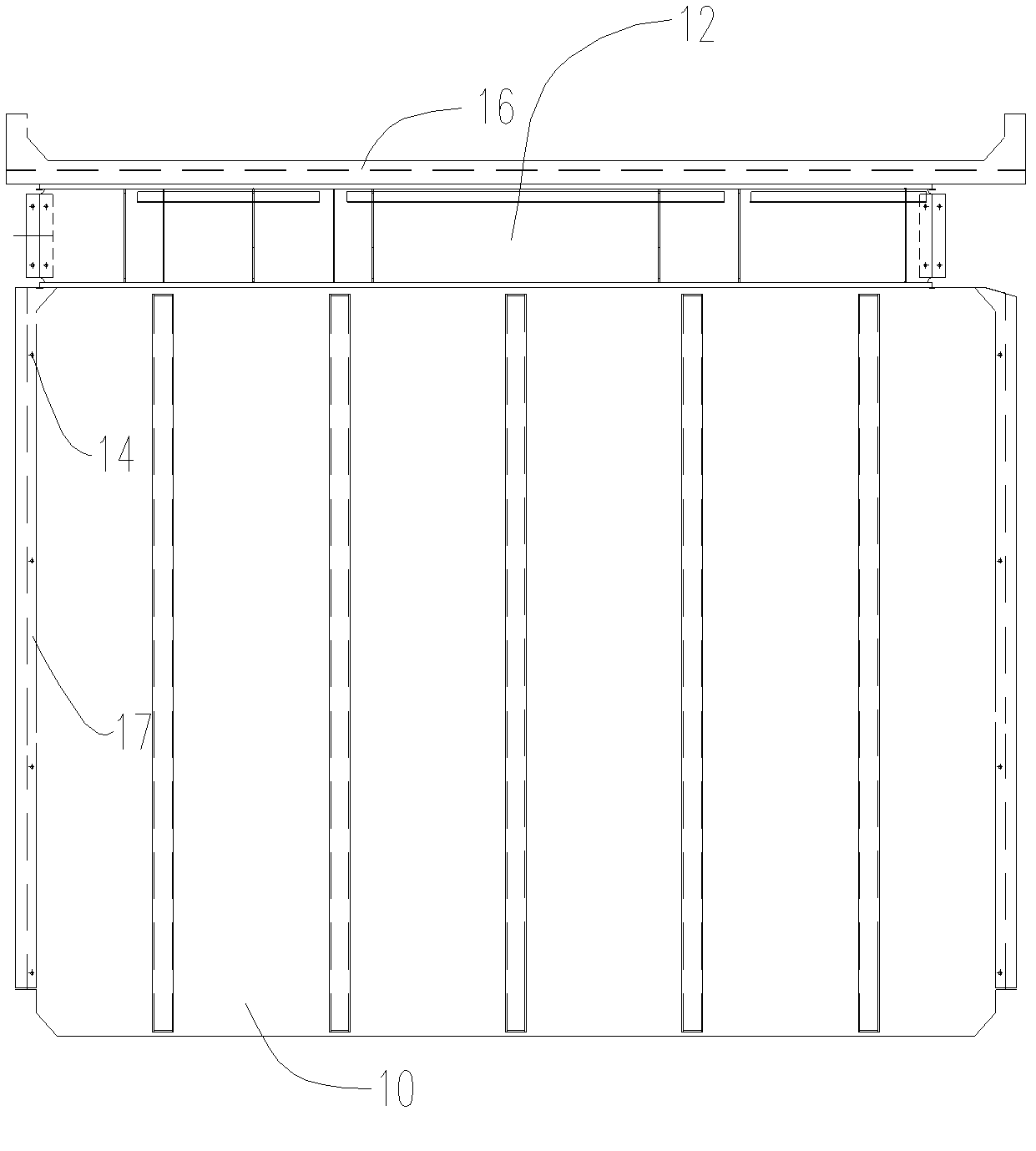

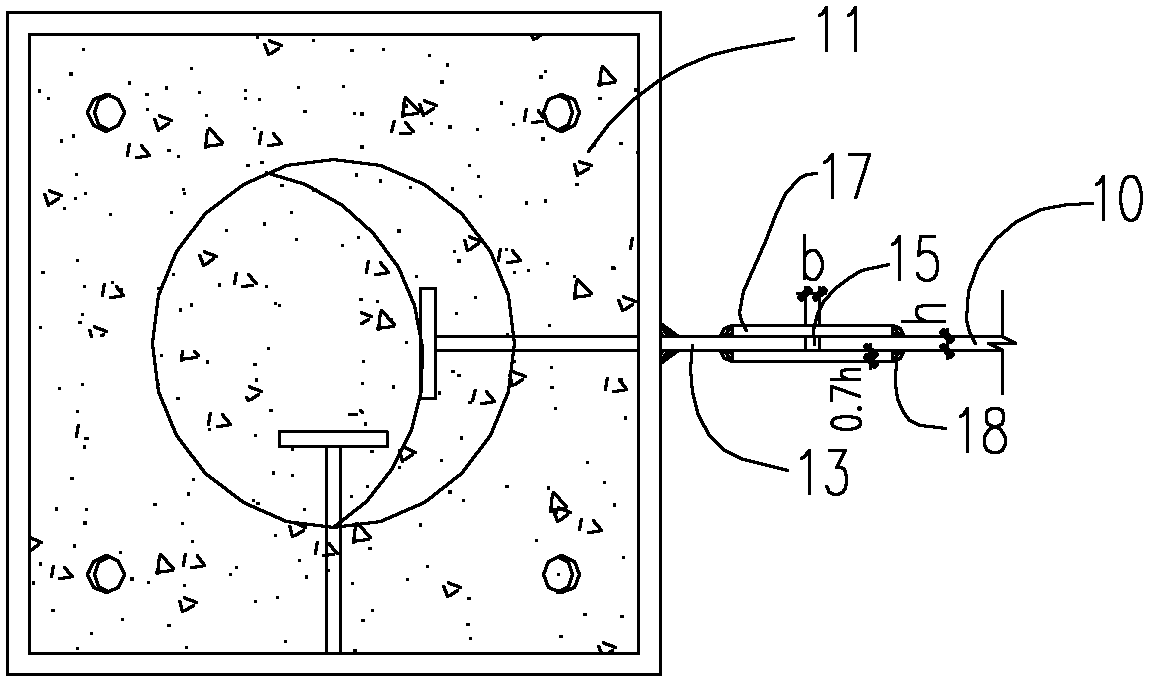

[0012] Such as figure 1 , 2 As shown, a steel plate shear wall unit usually includes a steel plate shear wall 10 , steel frame columns 11 on both sides, and a frame beam 12 .

[0013] Wherein the two sides and the lower edge of the steel plate shear wall 10 are further combined with double splints 17, and the double splints 17 on both sides of the steel plate shear wall 10 are respectively provided with plural pairs of fixing holes (not shown in the figure), and the double splints 17 In the steel structure processing plant, it is processed integrally with the steel plate shear wall 10, and the side of the steel pipe frame column 11 corresponding to the steel plate shear wall 10 is provided with a first attached plate 13. Holes 14, the lower flange of the frame beam 12 and the steel plate shear wall 10 have been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com