New method for producing medium and large caliber alloy steel seamless pipe by utilizing radial forging technology

A radial forging and large-diameter technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problem of weakening the technical and economic advantages of radial forging forming technology alloy seamless pipes, large-diameter alloy steel pipes Billet production is difficult, it is difficult to achieve the expected goal, etc., to achieve the effect of reducing multiple reheating links, shortening heating time, and narrow deformation temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

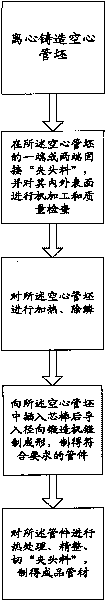

[0035] Such as figure 1 , figure 2 As shown, an embodiment of the radial forging machine used to produce Φ273×28×8500mm difficult-to-machine 1Cr18Ni9 austenitic stainless steel seamless steel pipe provided by the present invention, its process steps:

[0036] In the first step, the 1Cr18Ni9 molten steel refined outside the furnace is cast by a centrifugal casting machine into a hollow tube billet of Φ404×94mm with a length of 2130mm. In this step, the molten steel refined outside the furnace is the same as the prior art, and will not be repeated here; the centrifugal casting is carried out on a horizontal centrifugal casting machine with an angle of 0 degrees between the rotation axis of the mold and the horizontal. The cast hollow tube blank is a hollow tube blank with equal wall thickness and transparent ends. The centrifugal casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com