Buffering and energy absorbing structure

An energy-absorbing structure and grid structure technology, applied in the design characteristics of springs/shock absorbers, springs, shock absorbers, etc., can solve the problems of unreasonable energy-absorbing structures, low buffering and energy-absorbing efficiency, etc., and achieve good energy absorption. characteristics, enhanced energy absorption capacity, and the effect of technical means being simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments.

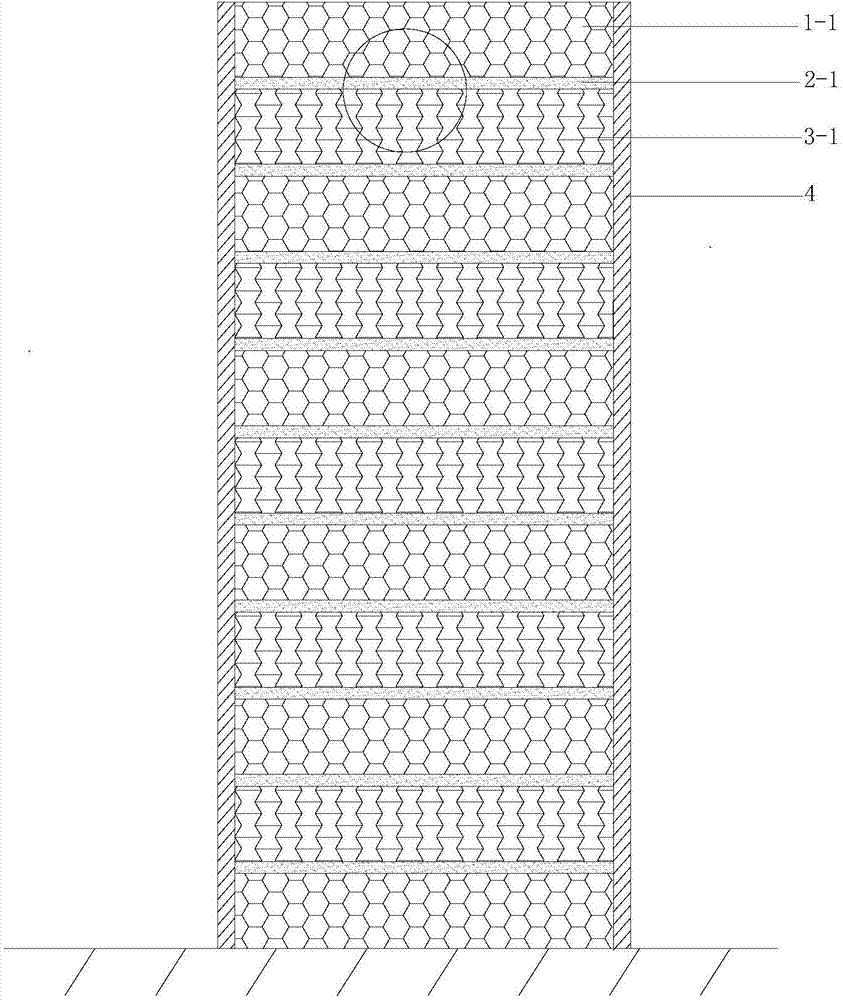

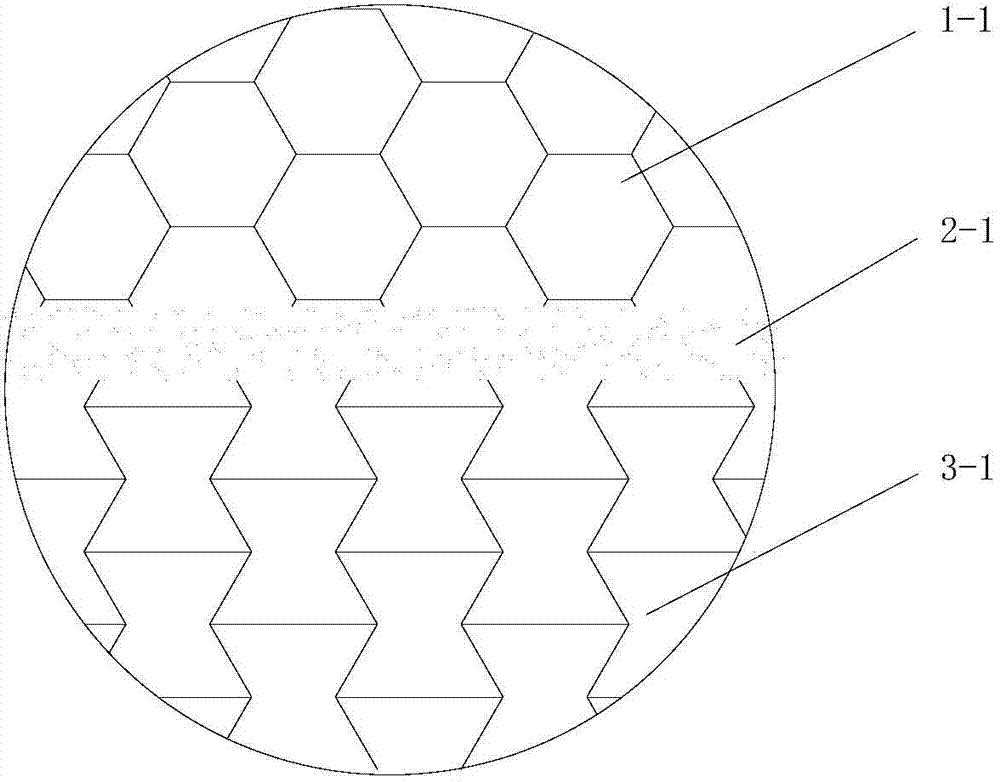

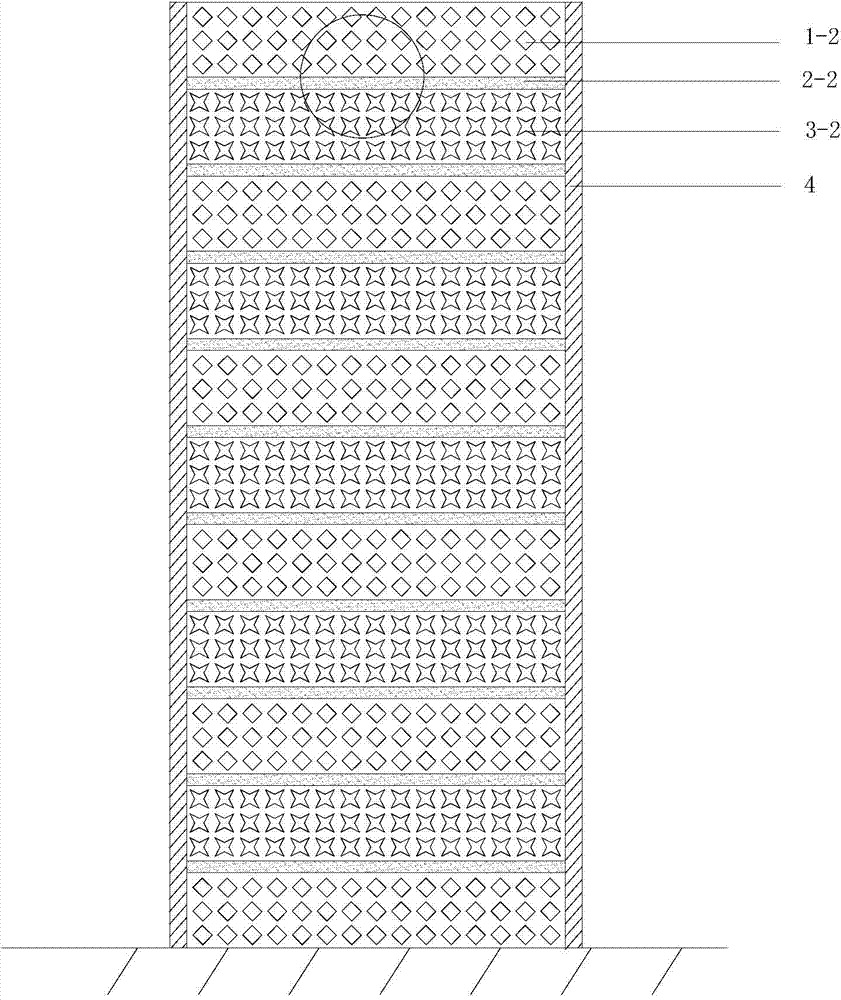

[0023] Such as Figures 1 to 6 shown. A buffer energy-absorbing structure of the present invention includes a shell 4, the buffer energy-absorbing structure is a multi-layer metal grid structure or porous foam structure filled in the shell 4, and the metal grid structure or porous foam structure of adjacent layers is The positive and negative Poisson's ratios are stacked alternately in the longitudinal direction.

[0024] The metal mesh structure of each layer is welded by brazing 2-1 (including the brazing between the metal mesh structure and the shell 4), and the porous foam structure of each layer is bonded by an adhesive 2-2 (including the porous foam structure and the shell 4 bonding between).

[0025] The Poisson's ratio of the metal grid structure or the porous foam structure at the collision end is positive.

[0026] The metal grid structure with a pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com