Air clamper for bore hole of thin-wall cylinder sleeve

A pneumatic clamping, thin-walled cylinder technology, applied in the direction of clamping device, positioning device, clamping, etc., can solve problems such as workpiece deformation and reduction of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

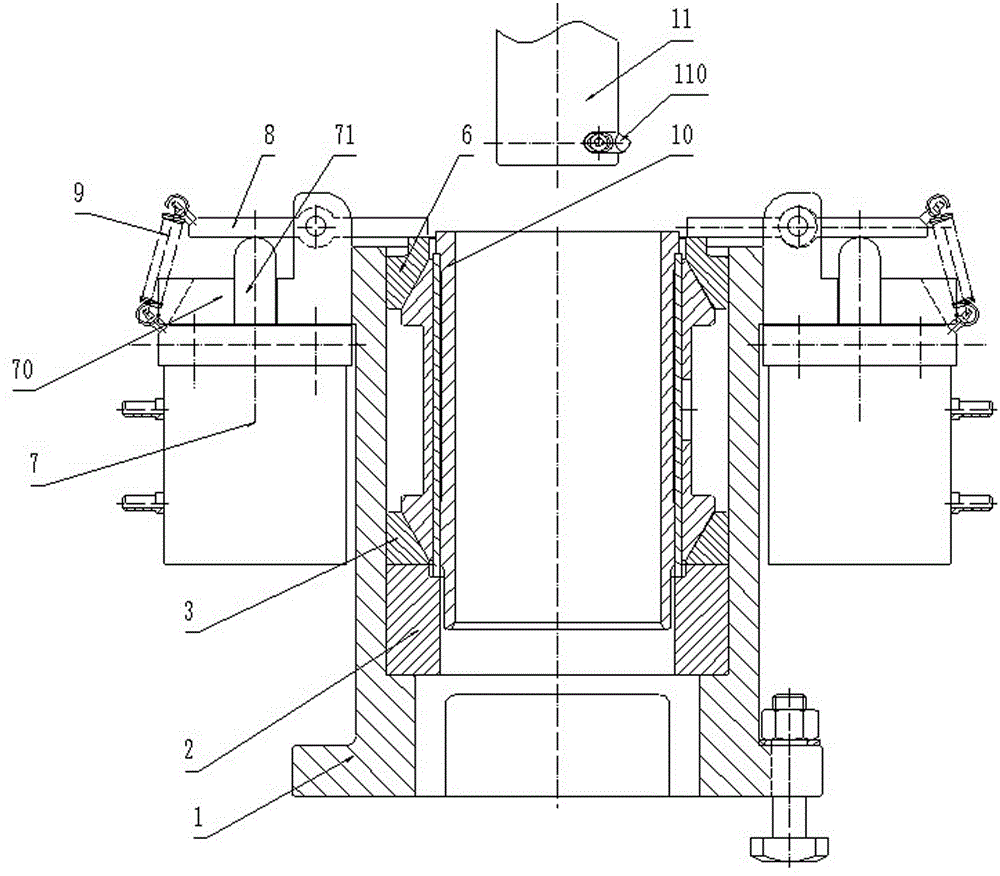

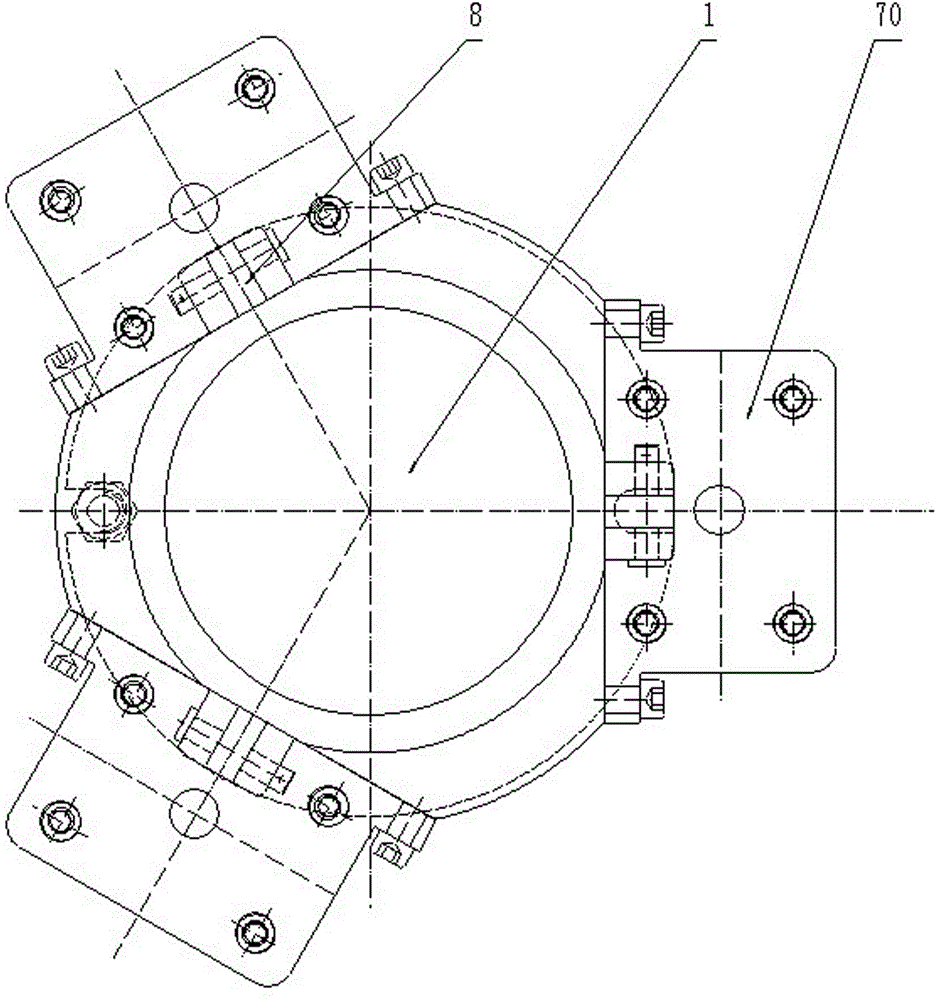

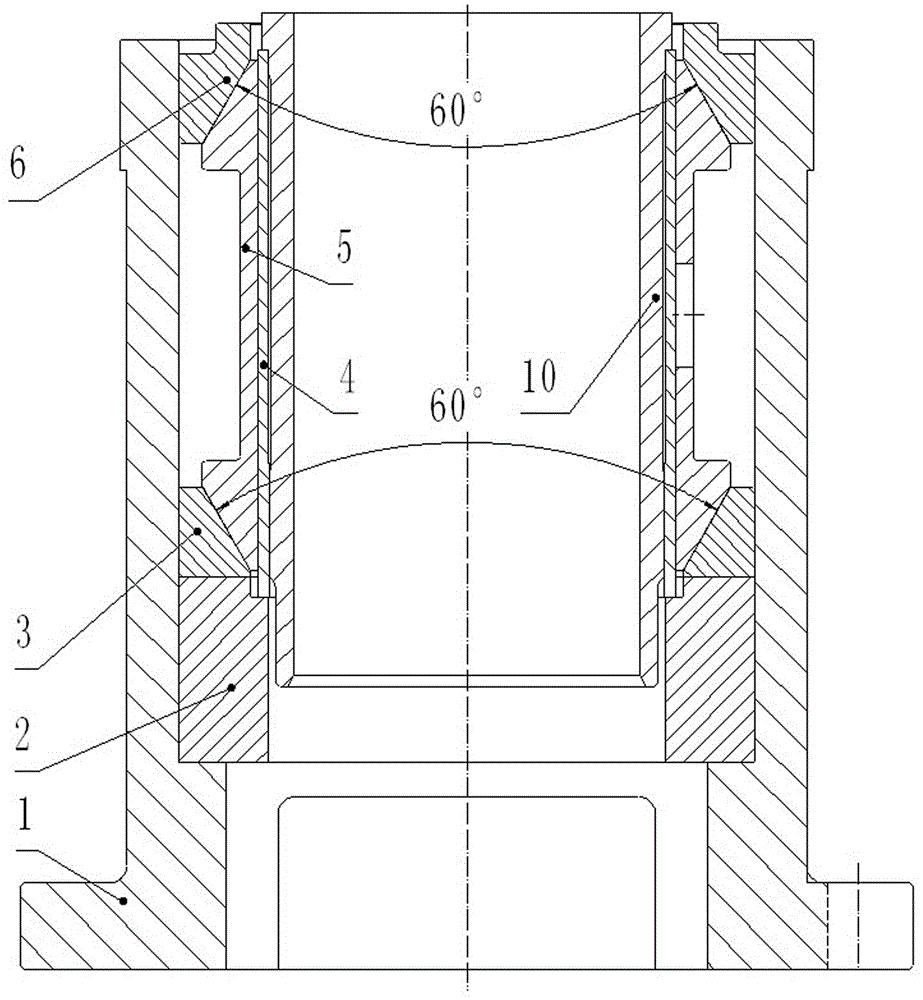

[0012] Such as figure 1 , figure 2 , image 3 It can be seen that the thin-walled cylinder liner boring pneumatic clamping device of the present invention includes a clamp body 1, a backing plate 2 is arranged at the bottom end of the inner cavity of the clamp body 1, and a lower cone with a tapered hole is arranged above the backing plate 2 Sleeve 3, the inner cavity of clamp body 1 above the lower taper sleeve 3 is provided with an elastic split sleeve 4 and a spring sleeve 5 sequentially in the radial direction, and the upper end of the spring sleeve 5 is provided with an upper taper sleeve 6 with a tapered hole, The upper and lower ends of the spring sleeve 5 cooperate with the taper surfaces of the upper taper sleeve 6 and the lower taper sleeve 3 respectively; along the circumferential direction of the clamp body 1, there are three sets of pressing devices uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com