Riveting machine

A technology of riveting machine and riveting mechanism, which is applied in the field of mechanical automation, can solve the problems of easy errors in manual operation, affecting the service life of products, and low work efficiency of workers, and achieves the effect of good riveting effect, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

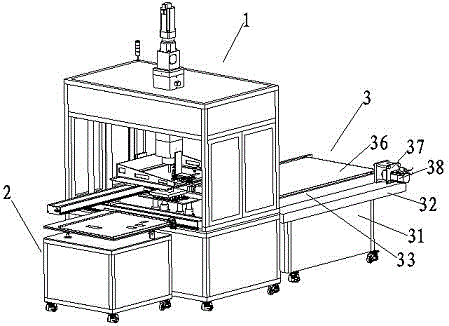

[0019] refer to figure 1 , a riveting machine, the riveting machine includes a riveting mechanism 1 fixed on the ground, a workpiece positioning mechanism 2 and a discharge mechanism 3 are respectively installed on the opposite outer sides of the riveting mechanism 1, and the workpiece is manually placed in the workpiece positioning mechanism 2, The workpiece positioning mechanism 2 positions the workpiece, and then the riveting mechanism 1 absorbs and rives the workpiece. After the riveting is completed, the riveting mechanism 1 transports the workpiece to the discharging mechanism 3;

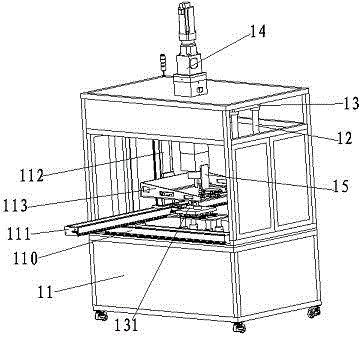

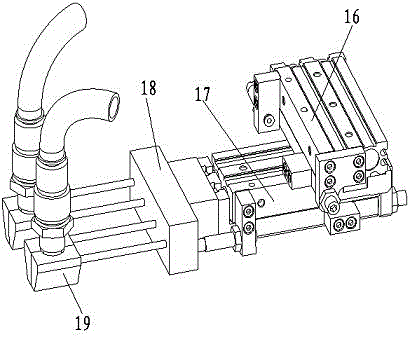

[0020] refer to Figures 1 to 6, the riveting mechanism 1 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com