Bidirectional and synchronous riveting equipment of U-type section part

A two-way synchronization, parts technology, applied in the field of two-way synchronous riveting equipment, achieves the effect of good safety and reliability, improved riveting function and efficiency, and solved inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

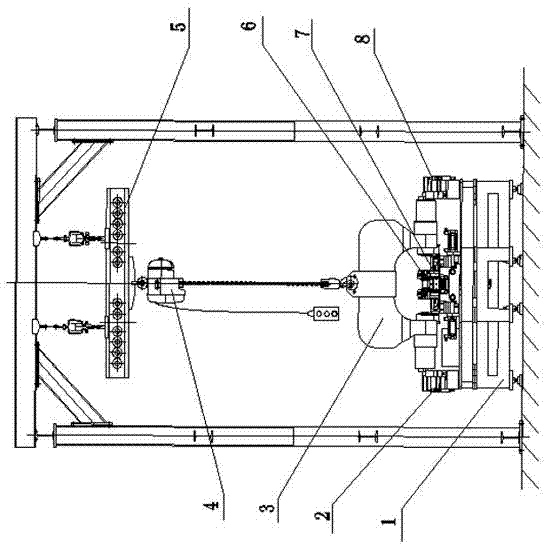

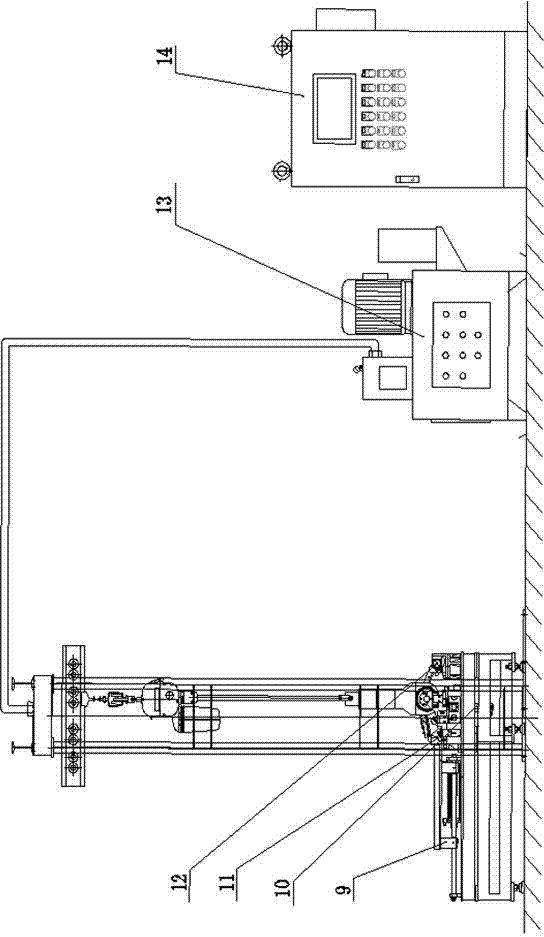

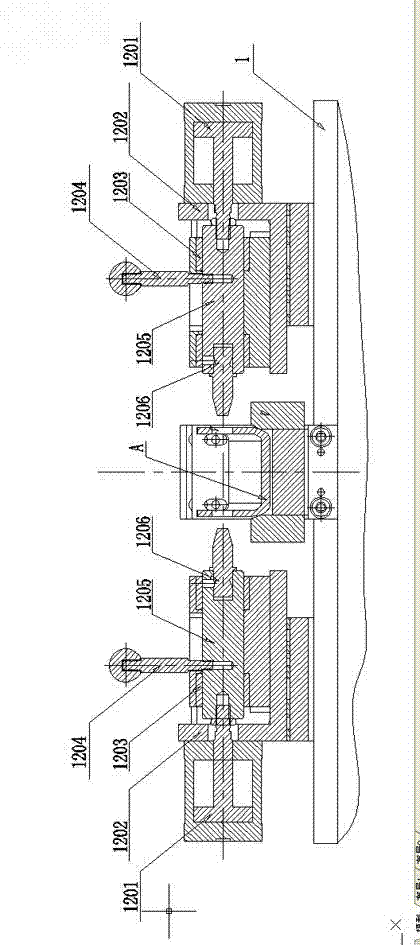

[0022] Such as figure 1 , figure 2 The two-way synchronous riveting equipment for U-section parts shown includes riveting fixture frame 1, riveting pliers left positioning base 2, riveting pliers right positioning base 8, bidirectional hydraulic synchronous riveting pliers 3, electric chain hoist 4, KPK suspension Steel frame 5, parts in place detection mechanism 6, pneumatic parts assembly push mechanism 7, pneumatic anti-pressure pad telescopic mechanism 9, pneumatic telescopic positioning and protection mechanism 10, pneumatic telescopic pin positioning mechanism 12, hydraulic power station 13, electrical control system 14. The pneumatic telescopic pin positioning mechanism 12 is arranged on the near end of the riveting fixture frame 1 along the length direction, and the middle of the riveting fixture frame along the length direction is a U-shaped cross-section part support pad 11, and the U-shaped cross-section part support pad Positioning pins are arranged on 11; U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com