Rivet rolling device for collar suturing needle rake for knitting suturing machine

A technology for knitting stitching and mechanically closing the collar, applied in the field of rolling riveting devices, can solve the problems that the collar can not be clamped tightly, the riveting force is difficult to control, the deformation of the collar can be improved, and the riveting effect can be improved and the riveting feed can be improved. The amount can be adjusted and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

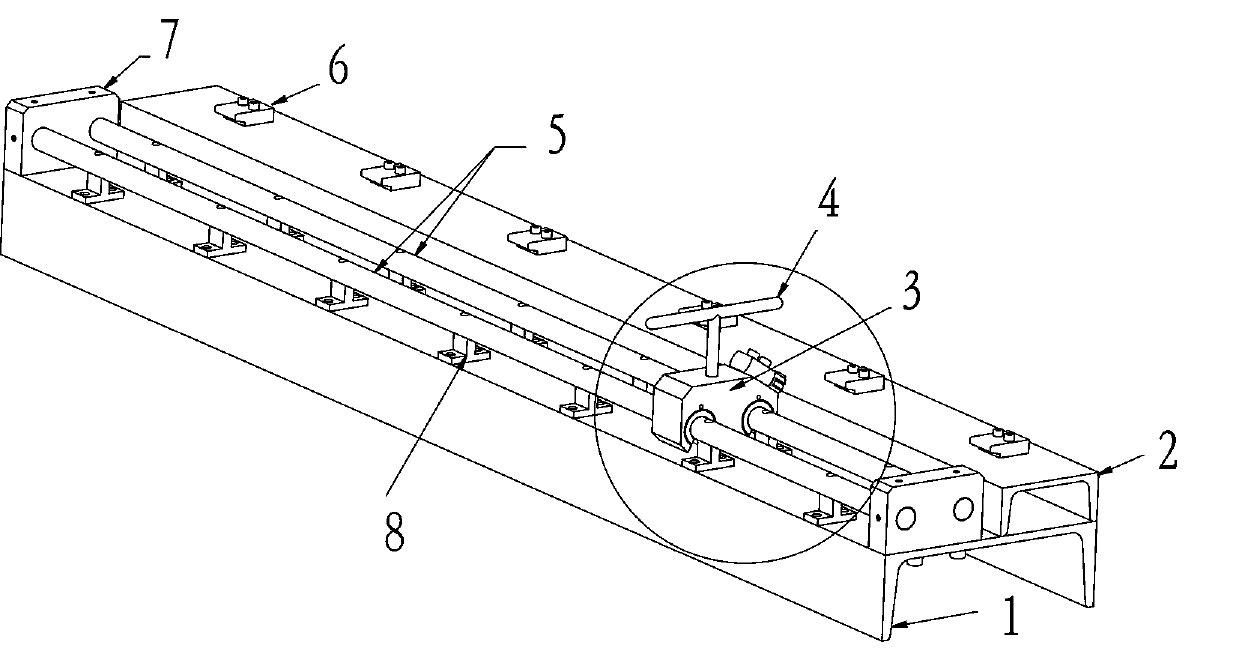

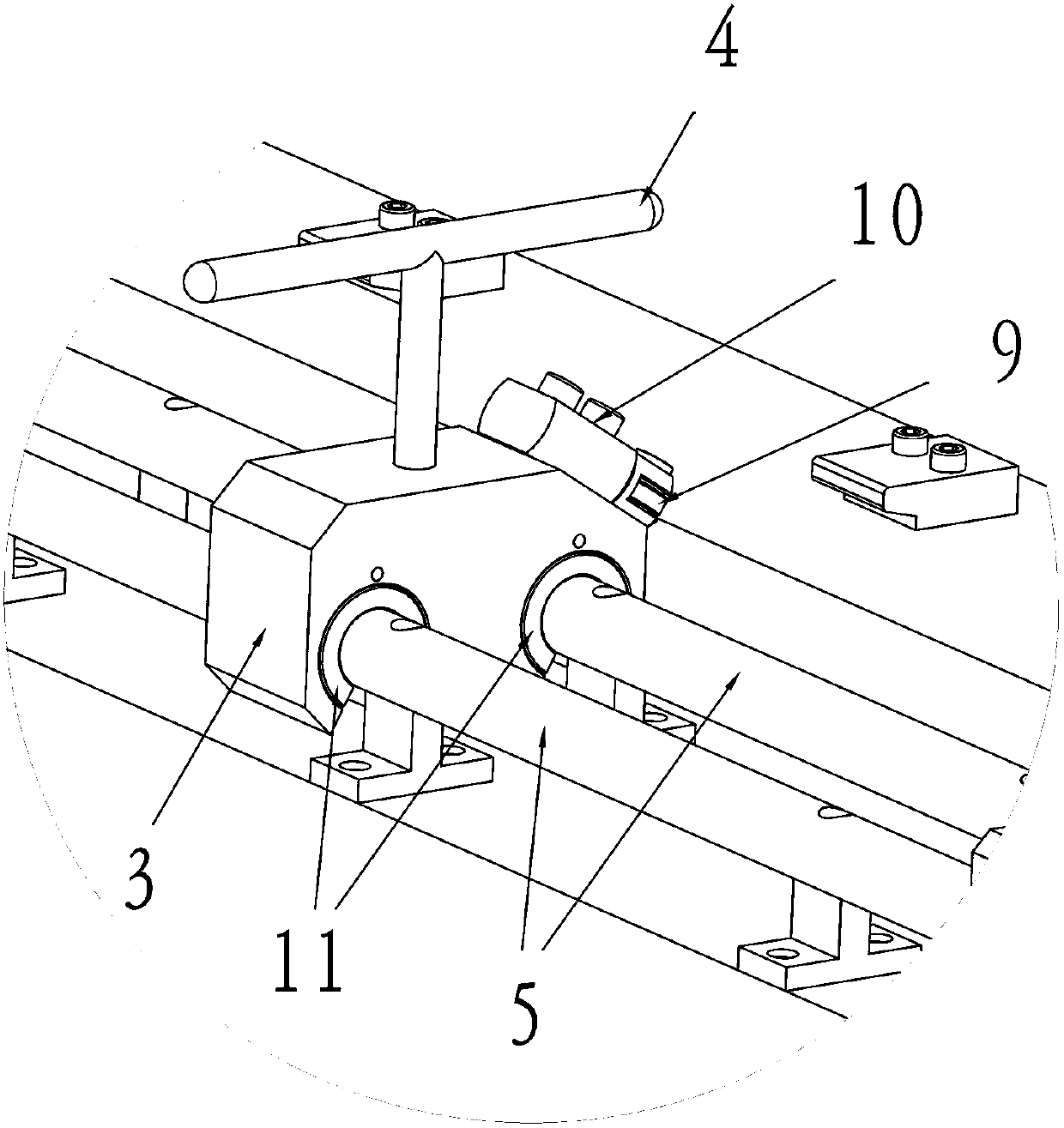

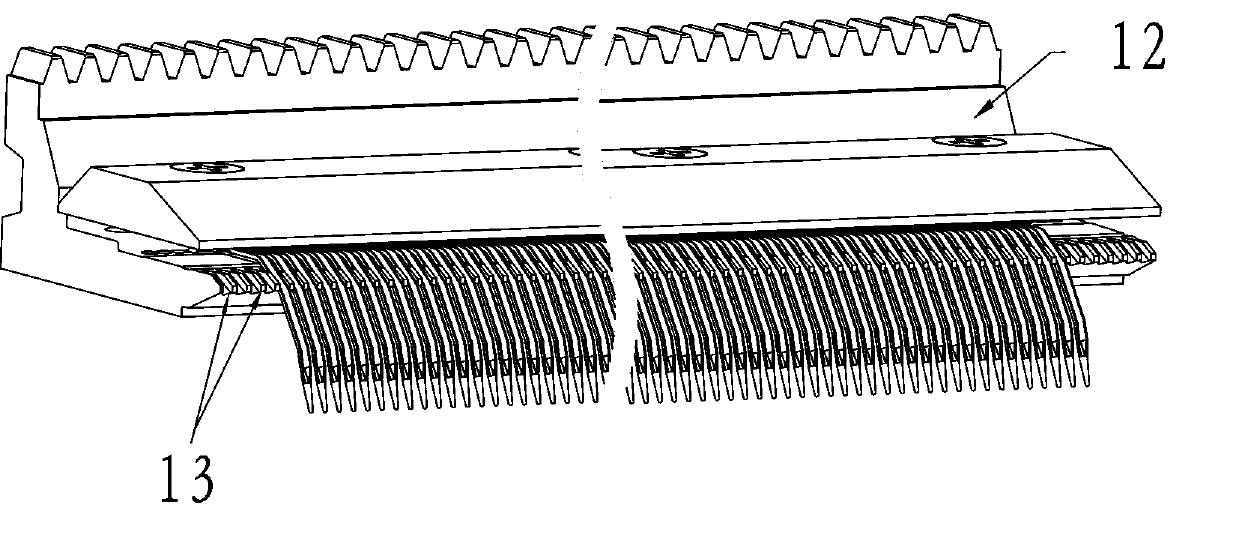

[0011] See attached picture. This embodiment includes a channel steel base 1, a channel steel boss 2, a needle rake positioning plate 6, a slide bar 5, a sliding seat 3, a roller bracket 10 and a roller 9; the channel steel boss 2 is fixed on the channel steel base 1 6 pin rake positioning platens 6 are fixed on the channel steel boss 2; the slide bar 5 has two pieces, both ends of which are fixed on the channel steel base 1 through the sliding seat baffle plate 7, and are located in front of the channel steel boss 2; The bottom of the slide bar 5 has seven slide bar supports 8; the slide seat 3 is sleeved on the two slide bars 5 through two linear bearings 11; the roller bracket 10 has mounting holes, and is fixed on the slide seat 3 by screws On the side close to the channel steel boss 2, the installation hole of the roller bracket 10 is a long slotted hole; the roller 9 is installed on the roller bracket 10; a T-shaped handle 4 is provided above the sliding seat 3.

[0012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com