Technology for improving riveting performance of nut

A riveting and crafting technology, which is applied in the direction of nuts, connecting components, threaded fasteners, etc., to achieve the effect of tight combination, reducing riveting gap and improving riveting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

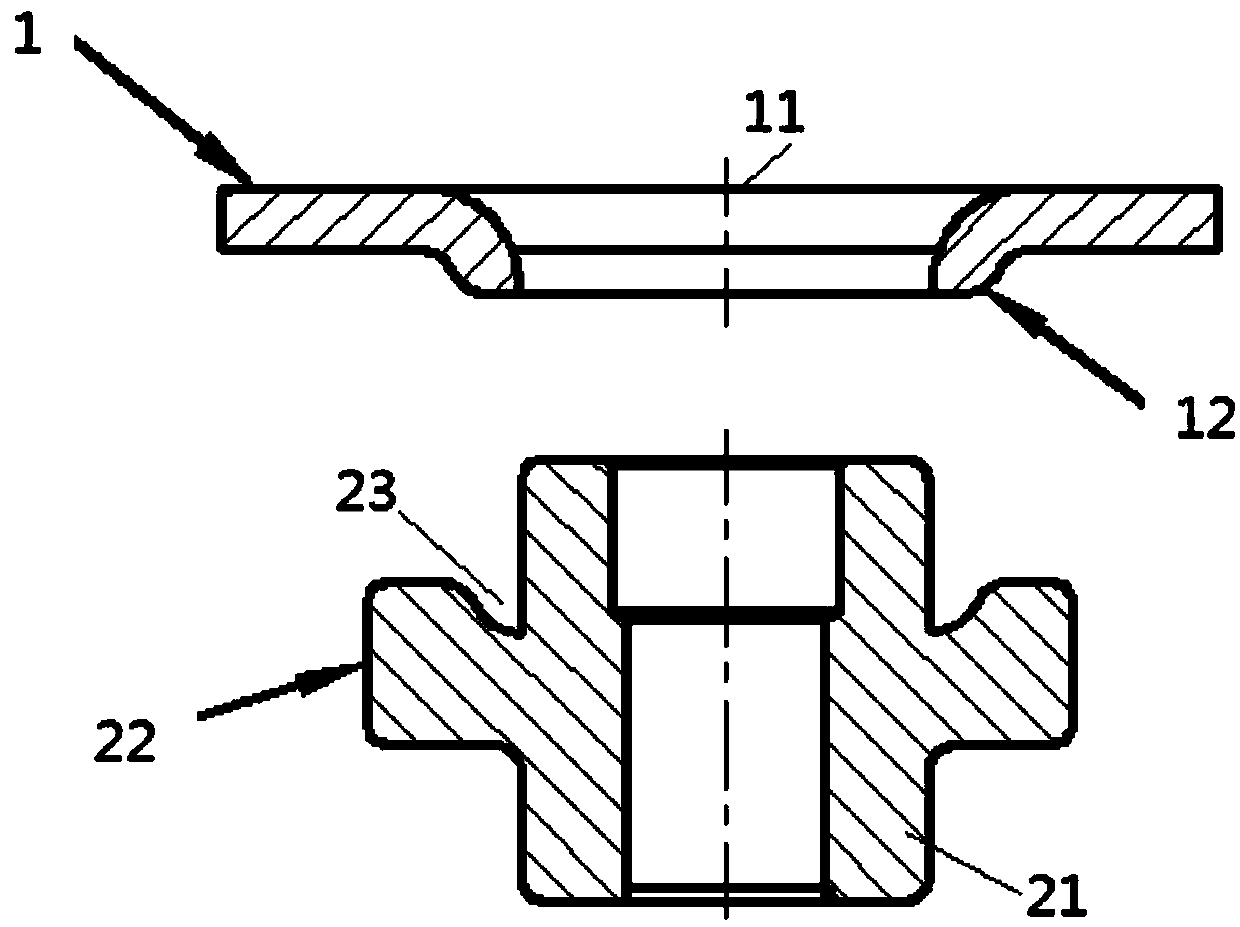

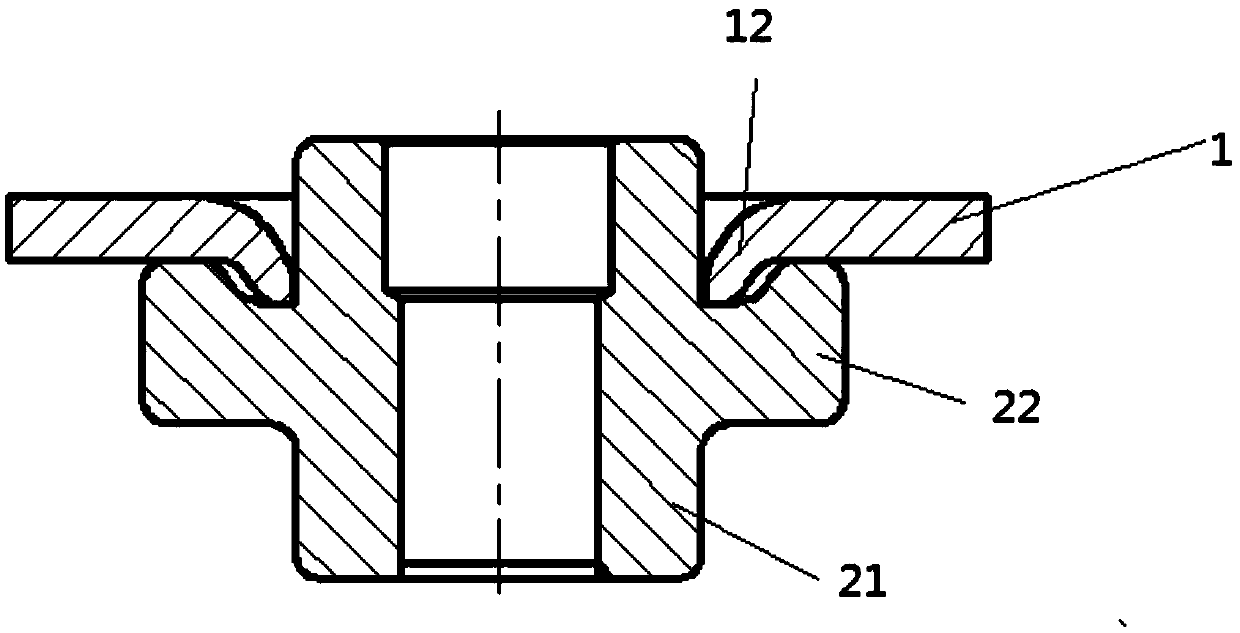

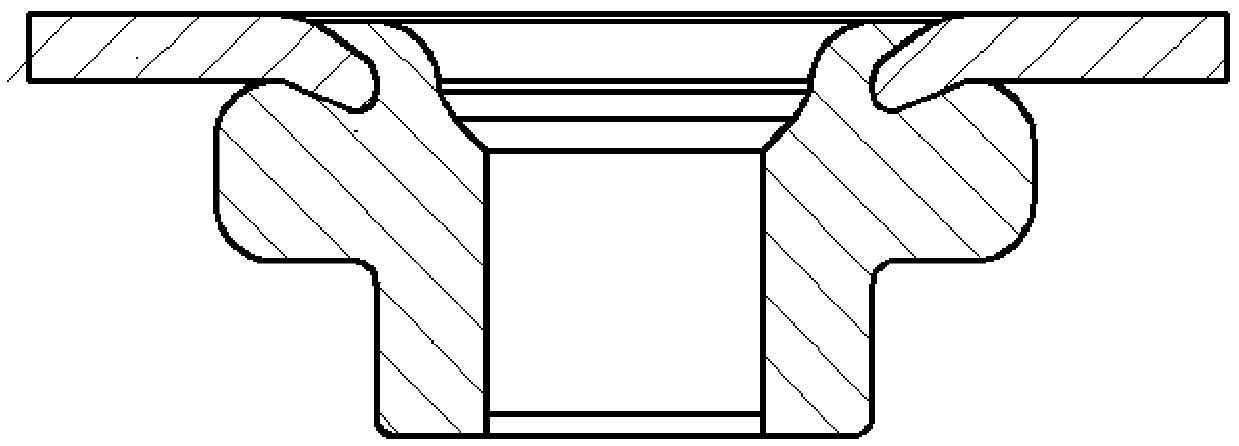

[0026] Such as figure 1 As shown, a process for improving the riveting performance of a nut includes the following steps:

[0027] (1) Pre-punch a pre-punched hole (11) on the part to be riveted (1), and perform flanging around the pre-punched hole (11) through a flanging process to form a downwardly curved arc flanging (12) ;

[0028] (2) The part to be riveted (1) is sleeved into the riveting nut from the arc-shaped flange (12), and after positioning, the upper die punch moves down to complete the riveting between the part and the riveting nut.

[0029] Wherein, the riveting nut includes a nut body 21 and a protrusion 22 provided on the nut body. The protrusion 22 is provided with a slot 23. One side of the slot 23 is vertically downward along the nut body 21. , The other side is arc-shaped. The slot 23 has a depth of 5-10 mm, a bottom width of 2-3 mm, and a top width of 5-8 mm. The raised portion 22 is an annular raised block projecting outward from the side of the nut body 21,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Top width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com