Reinforced precision cast brake shoe assembly

A technology of precision casting and brake shoes, applied in the direction of brake parts, brake types, brake components, etc., it can solve the problems of affecting the braking effect, overheating of the friction lining, over-adjustment and other problems, so as to improve the service life and durability. The effect of reducing the riveting gap and reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

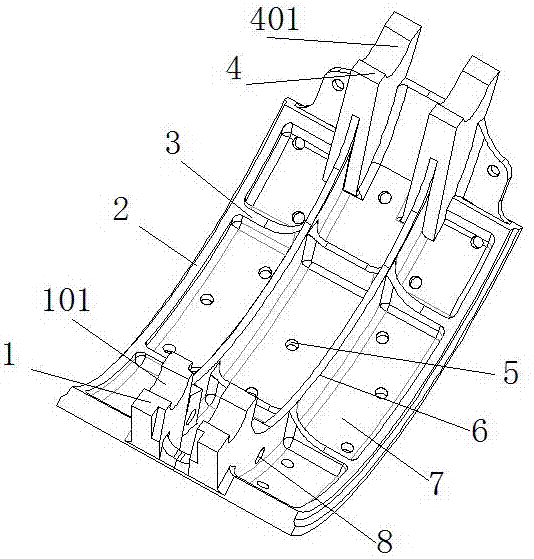

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

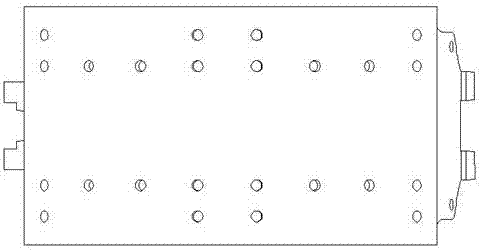

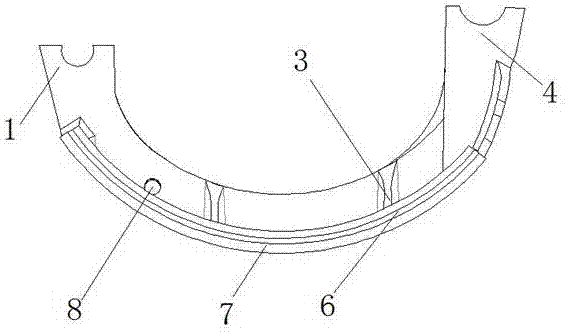

[0027] 3. As shown in the figure, a reinforced precision casting brake shoe assembly is formed by connecting an arc-shaped shoe panel 7 and two tendon plates 6 arranged in parallel on the inner arc surface of the hoof panel 7. One end of the hoof rib plate 6 is The supporting pin end 4, the other end is the driving pin end 1, and the ends of the driving pin end 1 and the supporting pin end 4 are respectively provided with a first arc-shaped groove 101 and a second arc-shaped groove 401; it is characterized in that : the inner surface of the hoof panel 7 is provided with first ribs 2 with a fully enclosed structure, and the inner surface of the first rib 2 and the inner surface of the hoof panel 7 are provided with several groups of second ribs 3 perpendicular to the hoof rib plate 6 ; The inner surface of the hoof panel 7 is paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com