Turnup side riveting die of automobile clutch cover assembly

A clutch cover and riveting die technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as unguaranteed product quality, irregular deformation, and impact on production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

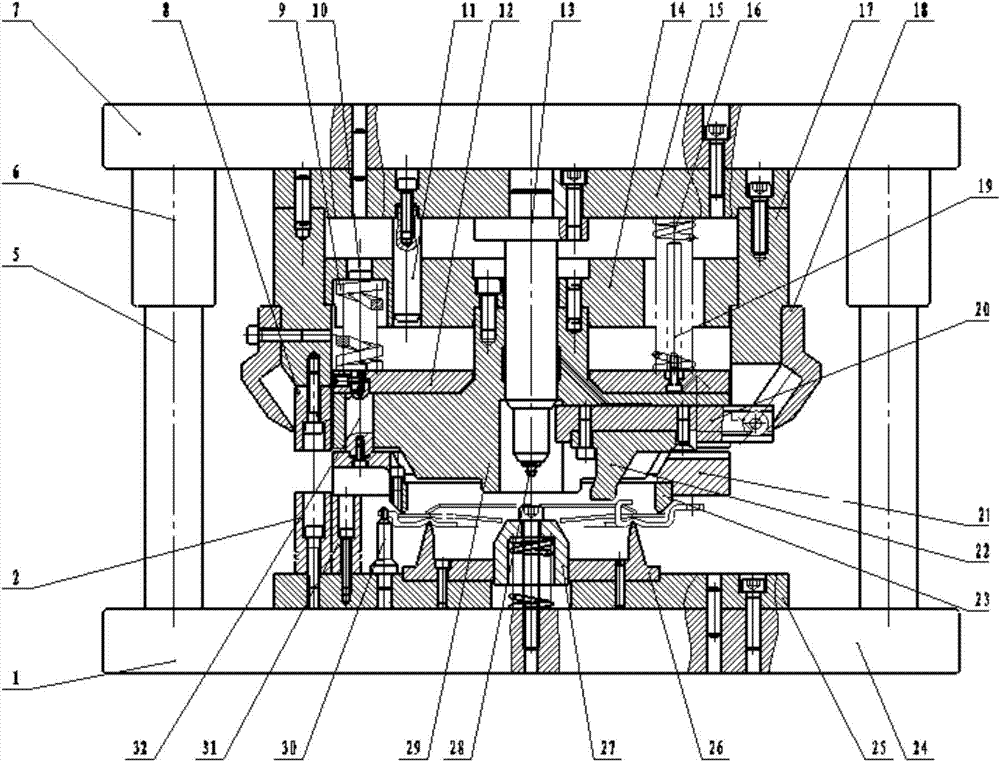

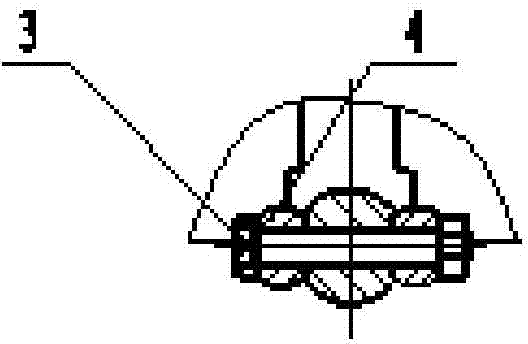

[0013] Referring to the accompanying drawings, the CP-type automobile clutch cover assembly flip riveting die includes an upper mold base 7 and a lower mold base 1, and the upper mold base 7 and the lower mold base 1 are connected by a guide sleeve 6 and a guide post 5 Guided installation, upper support plate is fixedly installed on the lower surface of the upper mold base 1, a backing plate is fixedly installed on the upper surface of the lower mold base, a cylindrical shell 17 is fixedly installed on the lower end of the upper support plate, and a reset ring is installed on the lower end of the shell 17 , the lower end of the reset ring is equipped with a guide wheel 4, the reset ring has a tapered cavity, a mandrel 13 is fixedly installed on the upper support plate, and the outer sliding sleeve of the mandrel 13 is equipped with a middle guide plate 14, a middle core seat, the middle guide plate and the middle core The seat is fixedly connected, the lower end of the middle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com