Method for improving carbon fiber felt needling efficiency

A technology of carbon fiber felt and carbon fiber, which is applied in the field of improving the needle punching efficiency of carbon fiber felt, can solve the problems of increased strength between carbon fiber oxygen-enriched wire needle felt layers, low fiber bundle formation efficiency, and small carbon fiber bundle friction, etc., to achieve improved needle punching Stabbing efficiency, increased interlayer strength, and enhanced riveting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

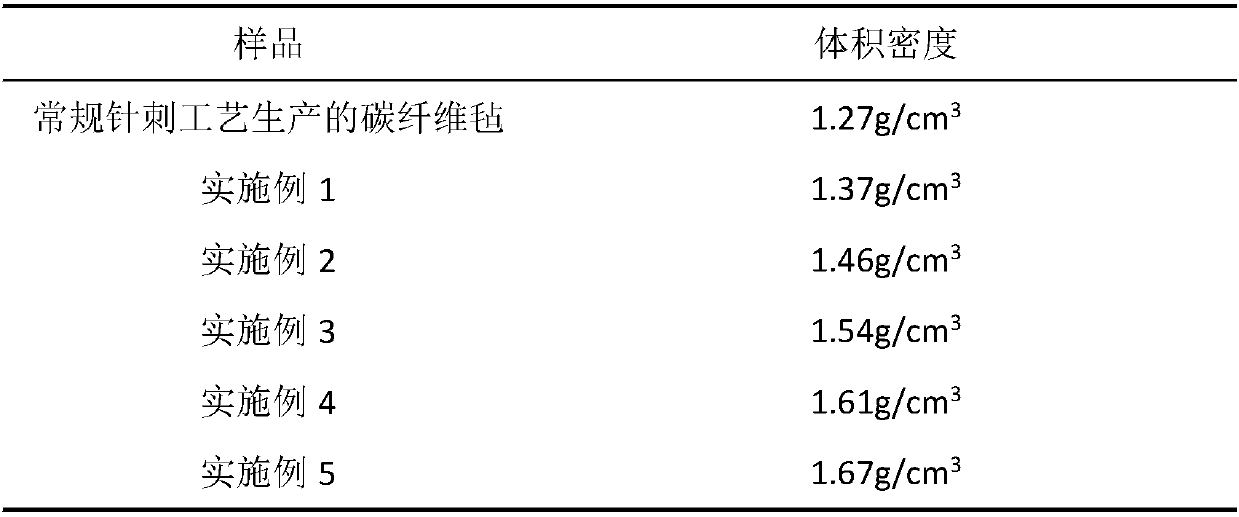

Examples

Embodiment 1

[0008] After the carbon fiber has been opened, carded and laid, the carbon fiber web passes through the upper surface of the acupuncture table at a conveying speed of 10m / min, and the fluffy carbon fiber web is subjected to negative pressure adsorption under the condition of a negative pressure of 0.1MPa generated by a vacuum pump. , the adsorbed carbon fiber mesh shrinks in the direction of negative pressure operation, and the needles on the upper needle punching board above the needle punching table needle the adsorbed carbon fiber mesh at a frequency of 1000 times / min, and the density of the needles on the upper needle punching board is 2000 pieces / m. The carbon fiber felt after negative pressure needle punching was cut and weighed.

Embodiment 2

[0010] When the carbon fiber web after the carbon fiber has been opened, carded and laid passes through the upper surface of the needle punching table at a conveying speed of 15m / min, under the condition that the negative pressure generated by the centrifugal fan is 0.1MPa, negative pressure is applied to the fluffy carbon fiber web. Adsorption, the carbon fiber mesh after adsorption shrinks in the direction of negative pressure operation, and the needles on the upper needle punching board above the needle punching table perform needle punching on the adsorbed carbon fiber mesh at a frequency of 1200 times / min, and the density of the needles on the upper needle punching board is 2500 Pieces / m. The carbon fiber felt after negative pressure needle punching was cut and weighed.

Embodiment 3

[0012] After the carbon fiber has been opened, carded and laid, the carbon fiber web passes through the upper surface of the acupuncture table at a conveying speed of 20m / min, and the fluffy carbon fiber web is subjected to negative pressure adsorption under the condition of a negative pressure of 0.1MPa generated by a vacuum pump. , the adsorbed carbon fiber mesh shrinks in the direction of negative pressure operation, and the needles on the upper needle punching board above the needle punching table perform acupuncture on the adsorbed carbon fiber mesh at a frequency of 1500 times / min, and the needle density of the upper needle punching board is 3000 pieces / m. The carbon fiber felt after negative pressure needle punching was cut and weighed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com