Gas-liquid pressurized riveting machine

A gas-liquid pressurization, riveting machine technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of low pressure riveting efficiency, troublesome replacement of molds, troublesome operation and maintenance, etc., to achieve convenient operation and maintenance, The effect of convenient replacement of molds and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

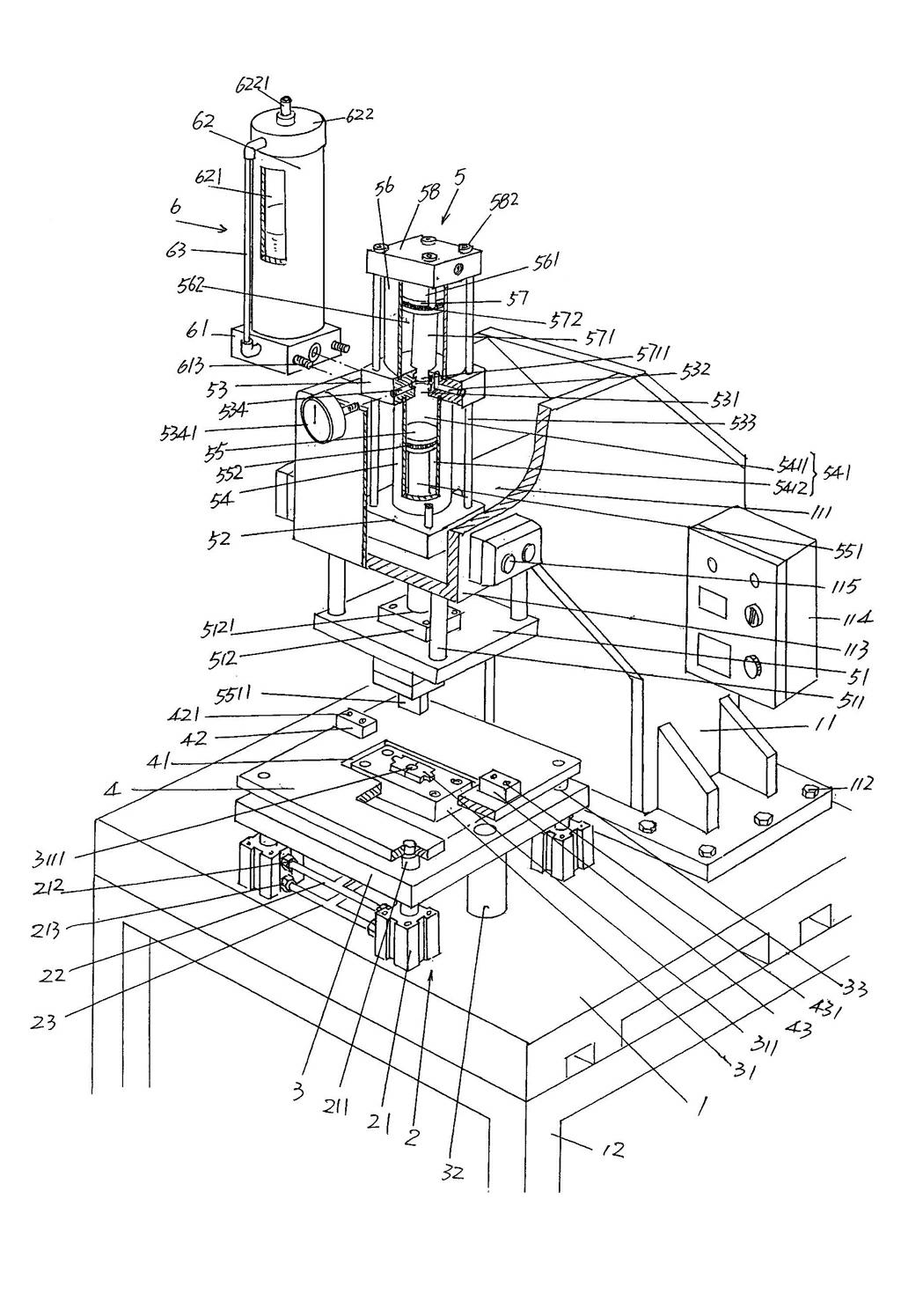

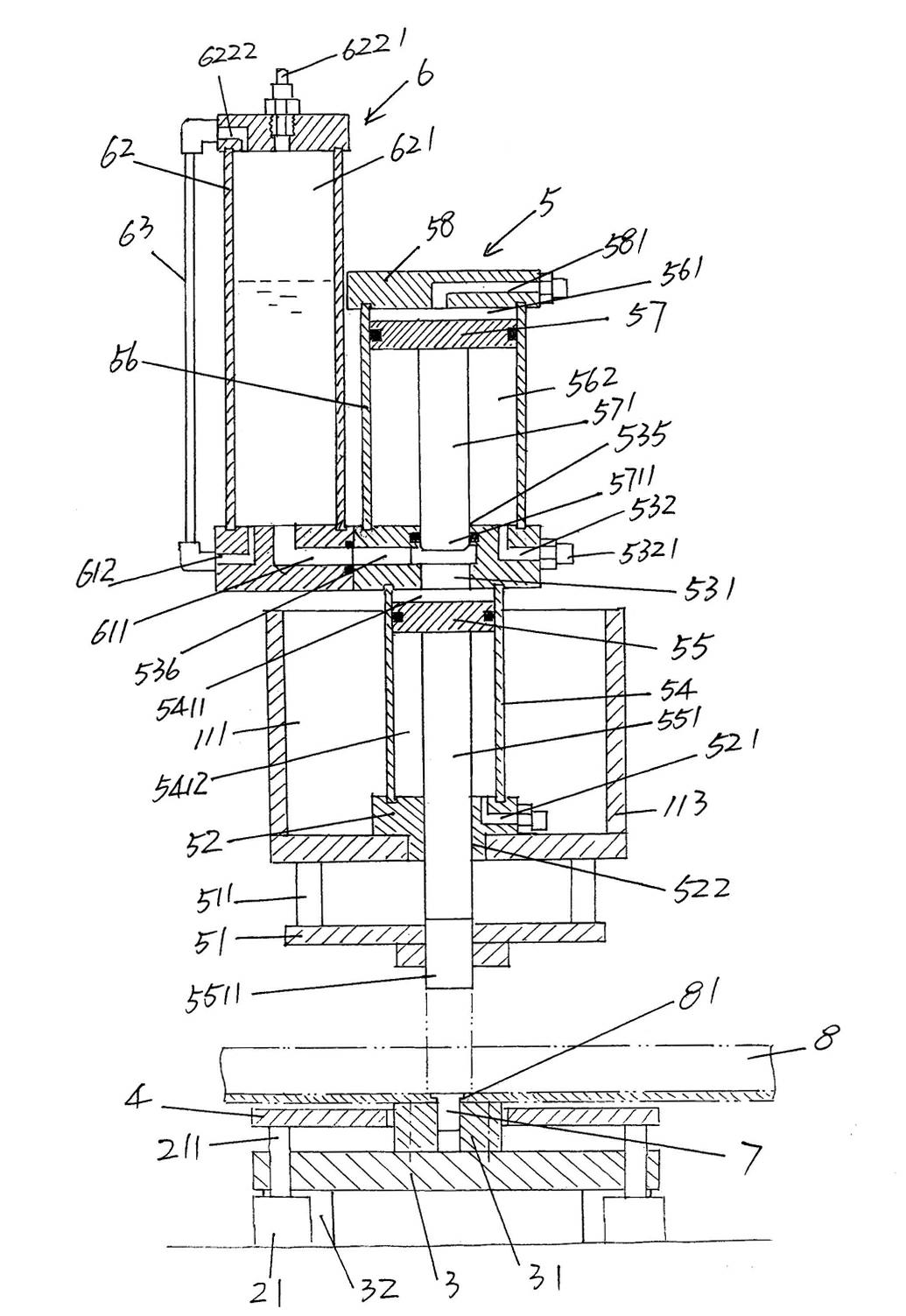

[0023] Please see figure 1 and figure 2 , a machine base platform 1 with support legs 12 (also called support feet) and set on the floor of the job site in use is given, on the surface of the machine base platform 1 facing upwards and on the machine base One side of the platform 1 is fixed with a base 11 by a first screw 112 , the overall shape of the base 11 is like the shape of Arabic numeral 7, and a base cavity 111 is formed.

[0024] The preferred but non-limiting structure of the ejector plate lifting mechanism 2 provided on the aforementioned base platform 1 is as follows: a group of action cylinders 21, a first communication pipe 22 and a second communication pipe 23 are included, and a group of action cylinders 21, a first communication pipe 22 and a second communication pipe 23 are included. The number of cylinders 21 is four, and they are fixed on the upward facing surface of the base platform 1 in the form of the Chinese character "口". There is one working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com