High-temperature-resistant electroplating-grade ABS resin and preparation method thereof

An ABS resin and electroplating-grade technology, which is applied in the field of high-temperature-resistant electroplating-grade ABS resin and its preparation, can solve the problems of poor electroplating adhesion and inability to meet heat-resistant electroplating ABS, and achieve excellent electroplating adhesion and excellent heat resistance performance, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

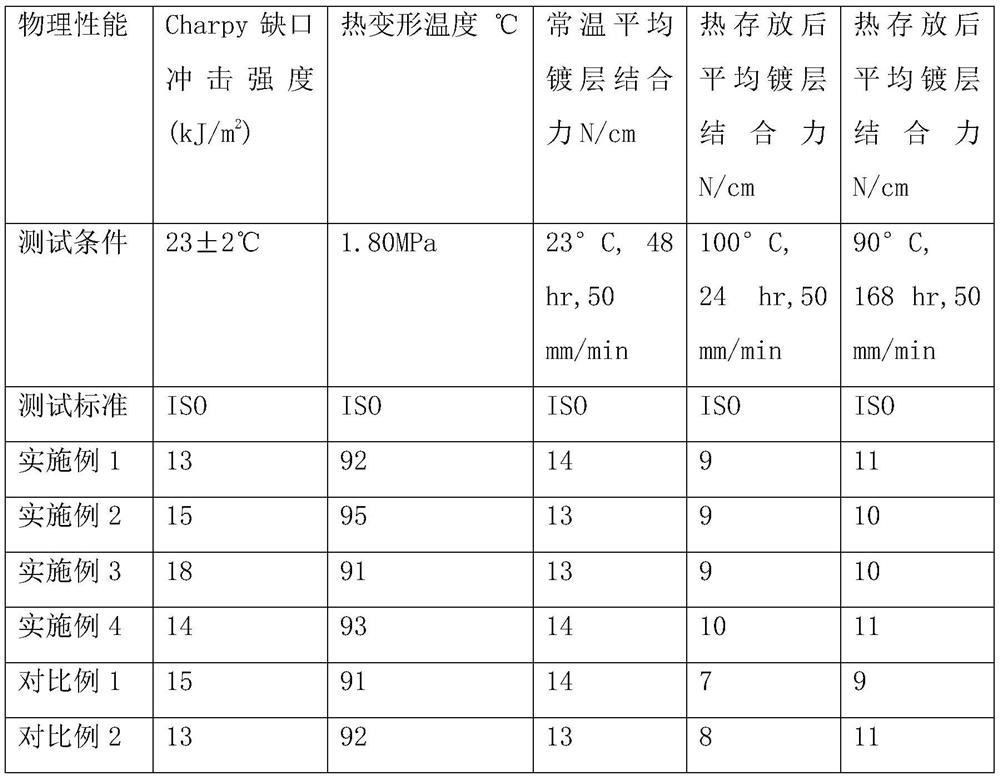

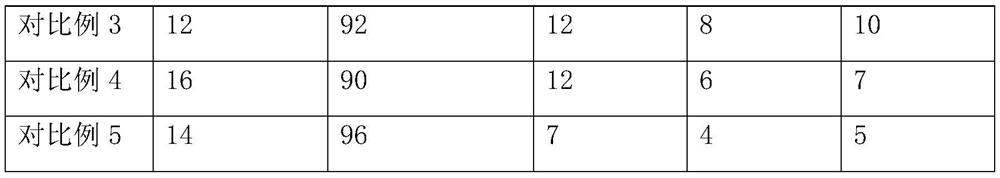

Examples

Embodiment 1

[0060] A preparation method of high temperature resistant electroplating grade ABS resin, comprising the following steps:

[0061] (1) By weight, 30 parts of ABS high rubber powder, 10 parts of styrene-maleic anhydride (SMA) heat resistant agent, 7 parts of kaolin, 0.7 part of silane coupling agent (methyl dodecyl dimethoxy base silane), 0.5 part of antioxidant (thiophenol) and 0.5 part of lubricant (erucamide) are mixed in a high-speed mixer to obtain a first-grade crude product; wherein, the speed of the high-speed mixer is 800r / min, and the mixing time 10min;

[0062] (2) By weight, 10 parts of ABS resins, 43 parts of hyperbranched styrene-acrylonitrile copolymers and the primary crude product are mixed in a high-speed mixer to obtain a secondary crude product; wherein, the high-speed mixer speed 800r / min, the mixing time is 10min;

[0063] (3) Put the secondary crude product into a twin-screw extruder, melt, extrude, cool, dry, and then pelletize in a pelletizer to obtai...

Embodiment 2

[0065] A preparation method of high temperature resistant electroplating grade ABS resin, comprising the following steps:

[0066] (1) By weight, 25 parts of ABS high rubber powder, 15 parts of heat-resistant agent styrene-maleic anhydride (SMA), 3 parts of kaolin, 0.7 part of new polymer coupling agent (MMCA), 0.5 part of anti- Oxygen agent (2,6-di-tert-butyl p-cresol) and 0.5 parts of lubricant (stearic acid complex ester) are mixed in high-speed mixer to obtain first-grade crude product; Wherein, high-speed mixer rotating speed is 800r / min, the mixing time is 10min;

[0067] (2) By weight, 15 parts of ABS resins, 42 parts of highly branched styrene-acrylonitrile copolymers and the primary crude product are mixed in a high-speed mixer to obtain a secondary crude product; wherein, the speed of the high-speed mixer is 800r / min, the mixing time is 10min;

[0068] (3) Put the secondary crude product into a twin-screw extruder, melt, extrude, cool, dry, and then pelletize in a...

Embodiment 3

[0070] A preparation method of high temperature resistant electroplating grade ABS resin, comprising the following steps:

[0071] (1) By weight, 35 parts of ABS high rubber powder, 12 parts of heat-resistant agent styrene-maleic anhydride (SMA), 0.1 part of kaolin, 0.3 part of new polymer coupling agent (MMCA), 0.1 part of anti- Oxygen agent (2,6-di-tert-butyl p-cresol) and 0.1 part of lubricant (stearic acid complex ester) are mixed in high-speed mixer to obtain first-grade crude product; Wherein, high-speed mixer rotating speed is 800r / min, the mixing time is 10min;

[0072] (2) By weight, 13 parts of ABS resins, 40 parts of highly branched styrene-acrylonitrile copolymers and the primary crude product are mixed in a high-speed mixer to obtain a secondary crude product; wherein, the high-speed mixer speed 800r / min, the mixing time is 10min;

[0073] (3) The same as step (3) method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com