Rotated riveting device

A riveting head and tooling technology, applied in the field of riveting equipment, can solve the problems of low production efficiency, complex structure, low riveting precision, etc., achieve good riveting effect, simple device structure, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

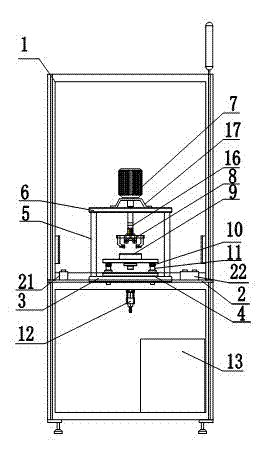

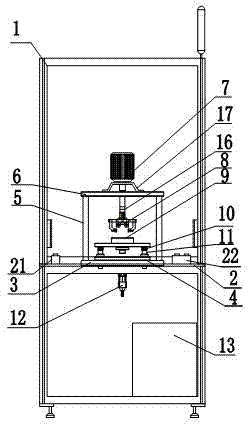

[0020] Such as figure 1 As shown in Fig. 2, the spin riveting device of the present invention includes a frame 1, a table top 2 is provided in the middle of the frame 1, a lower supporting surface 3 is provided on the table top 2, and on the lower supporting surface 3 A fixed plate 4 and a support column 5 are provided, an upper support surface 6 is provided on the support column 5, a motor 7 is provided on the upper support surface 6, the output end of the motor 7 is connected to a spin riveting head 8, and the lower tooling 9 passes through Spring 10 and guide column 11 are connected with cylinder 12, and electric box 13 is located at the bottom of described frame 1; In the opposite direction of described table top 2 operation, be provided with three-point assembly 14; Described motor 7 passes thrust bearing 15, spline The shaft 16 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com