Method for improving high-temperature creep performance of titanium alloy substrate

A high-temperature creep, titanium alloy technology, applied in metal material coating process, coating, melting spray plating, etc., can solve the effect of increasing the probability of brittle phase precipitation, increasing structural instability, and improving the creep resistance of alloys limited and other problems, to achieve the effect of inhibiting oxidation resistance, improving bonding strength, and alleviating thermal mismatch stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

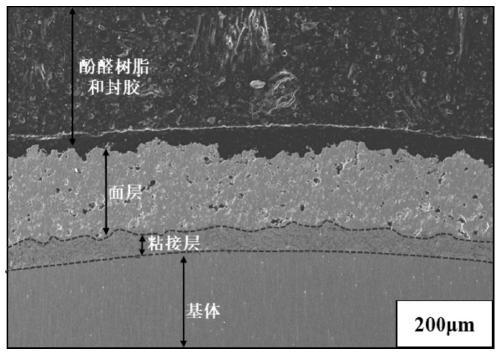

[0040] In this example, TA32 titanium alloy is used as the base material, which is an α-type titanium alloy with a size of Φ10×185mm, and the composition mass percentages are: 5.5% Al, 3.5% Sn, 3.0% Zr, 0.7% Mo, 0.3% Si, 0.4% Nb, 0.4% Ta, and the rest is Ti. The coating is a heat-blocking functional layer composed of a base layer and a surface layer, the material of the base layer is NiCrAlY (NiCrAlY), and the material of the surface layer is YSZ.

[0041] The thickness of the bottom layer is 80 μm, and the thickness of the surface layer is 300 μm.

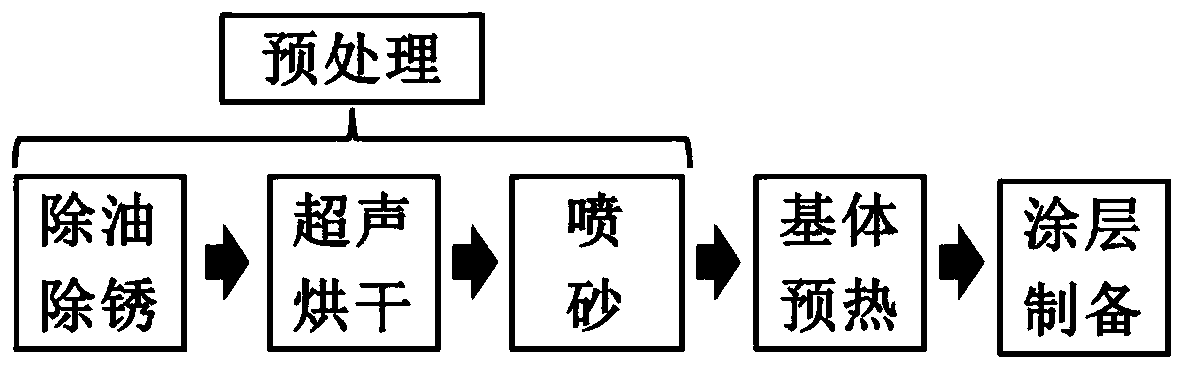

[0042] The specific implementation steps of preparing the thermal barrier functional layer on the surface of TA32 titanium alloy high temperature creep sample by high-energy plasma spraying technology are as follows:

[0043] 1) Substrate surface pretreatment

[0044] The surface of the TA32 titanium alloy used as the base material was degreased, decontaminated, polished and derusted, then ultrasonically cleaned with acetone solut...

Embodiment 2

[0050] 1) Substrate surface pretreatment

[0051] The surface of the β-type titanium alloy used as the base material was degreased, decontaminated, polished and derusted, then ultrasonically cleaned with acetone solution, then put into a drying oven for drying, and finally roughened with white corundum (#30). The process parameters are: gas pressure 0.6MPa, distance 80mm, angle 45°, roughness (Ra) value reaches 10.5μm.

[0052] 2) The treated substrate is preheated with high-energy plasma, and the specific process parameters are: current 300A, voltage 150V, argon flow rate 50L / min; the preheating temperature is controlled at about 90°C.

[0053] 3) Coating NiCrAlY metal powder on the surface of the preheated substrate by high-energy plasma spraying technology to form a bottom layer, and then spraying ceramic powder YSZ on the bottom layer by using high-energy plasma spraying technology to form a ceramic surface layer, the bottom layer The thickness is 50 μm, and the thickness...

Embodiment 3

[0055] 1) Substrate surface pretreatment

[0056] The surface of the α-type titanium alloy used as the base material is degreased, decontaminated, polished and derusted, then ultrasonically cleaned with acetone solution, then placed in a drying oven for drying, and finally roughened with white corundum (#30). The process parameters are: gas pressure 0.7MPa, distance 9cm, angle 60°, roughness (Ra) value reaches 11μm.

[0057] 2) The treated substrate is preheated with high-energy plasma, and the specific process parameters are: current 320A, voltage 120V, argon flow rate 40L / min; the preheating temperature is controlled at about 80°C.

[0058] 3) Coating NiCrAlY metal powder on the surface of the preheated substrate by high-energy plasma spraying technology to form a bottom layer, and then spraying ceramic powder YSZ on the bottom layer by using high-energy plasma spraying technology to form a ceramic surface layer, the bottom layer The thickness is 100 μm, and the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com