Titanium nail riveting device based on lateral ultrasonic energy field assistance and forming method thereof

A riveting device and field-assisted technology, which is applied in the field of aircraft assembly, can solve the problems of large riveting force, cracking of titanium nails, uneven deformation of titanium nails, etc., and achieve the goals of safe and convenient use, improved shaping, fatigue strength and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

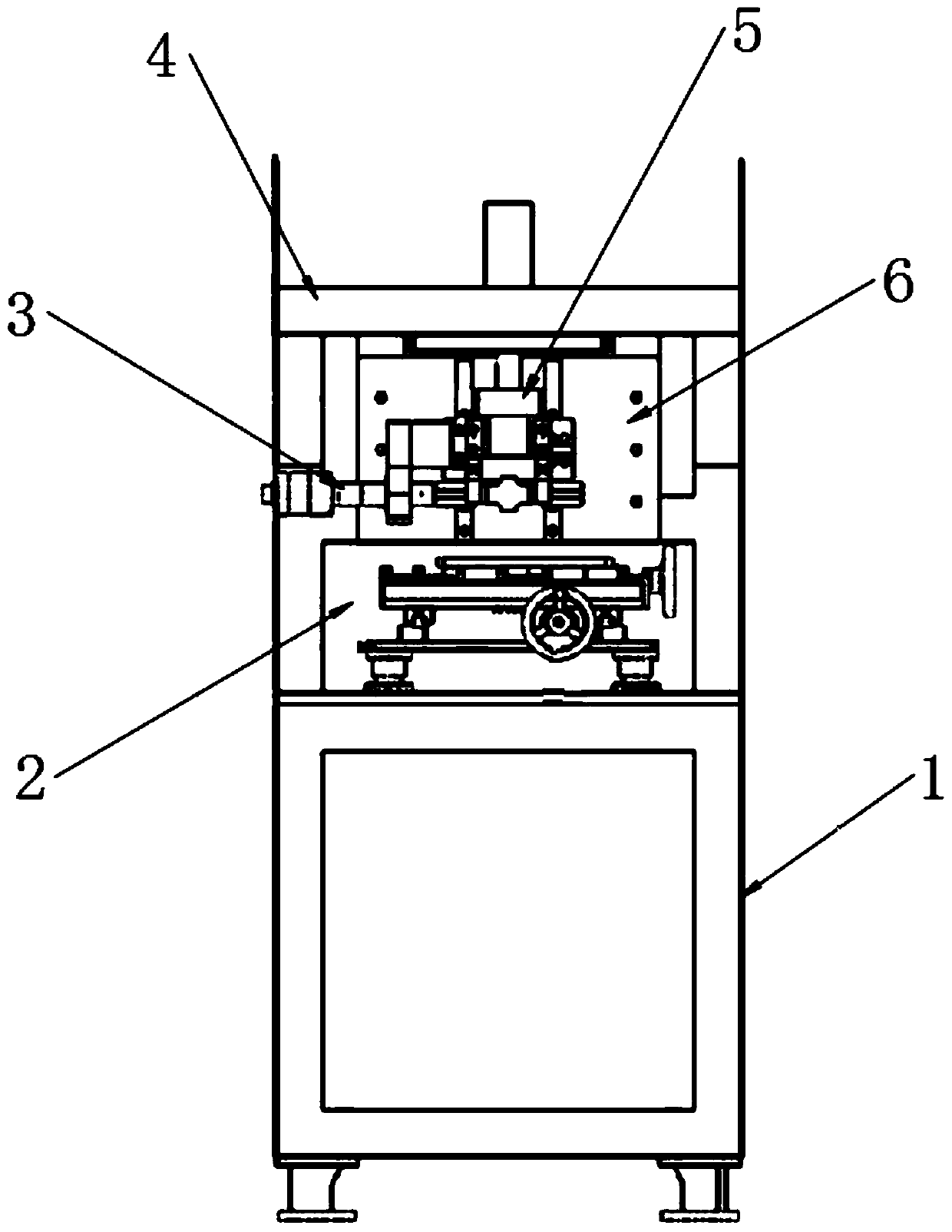

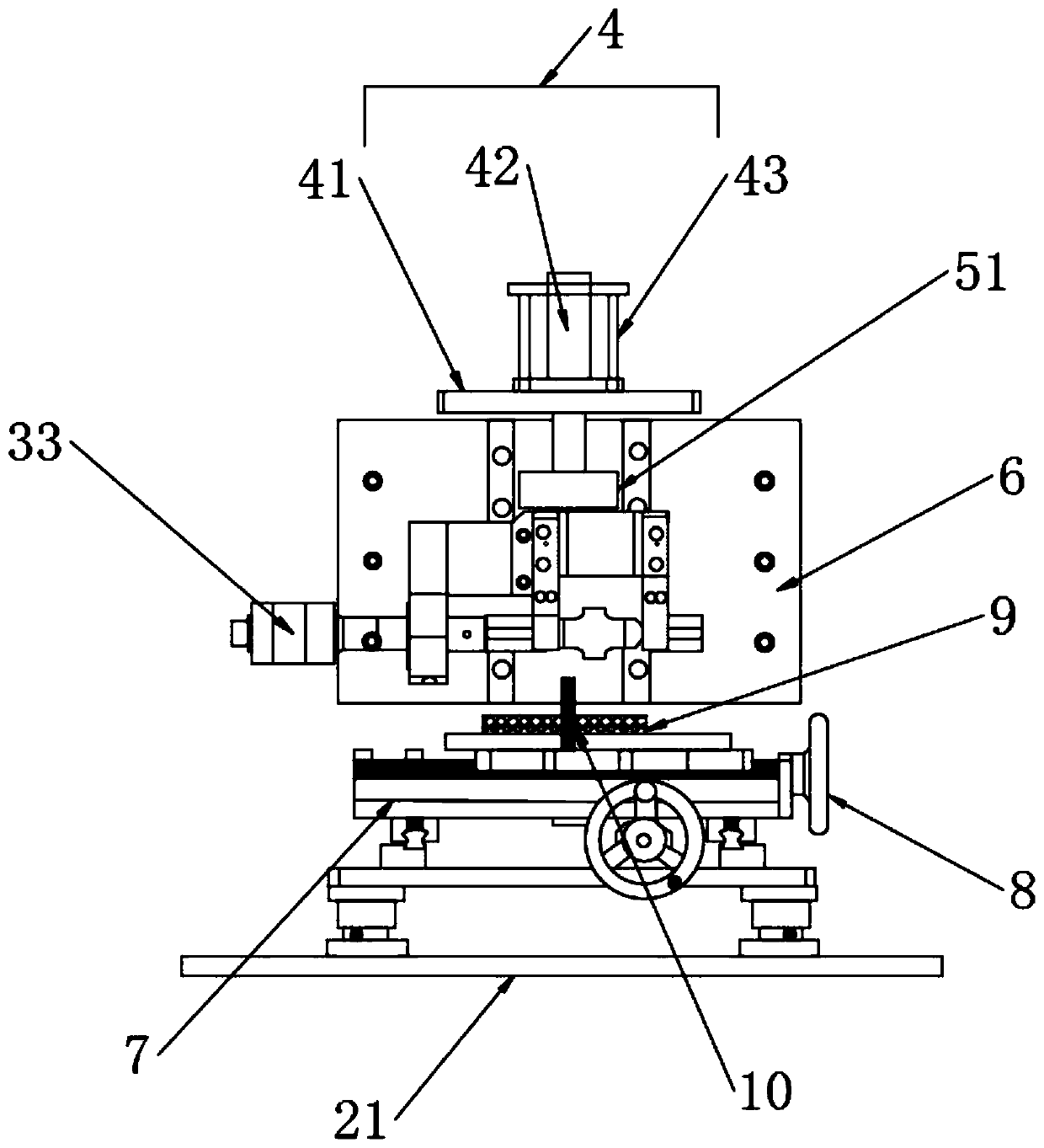

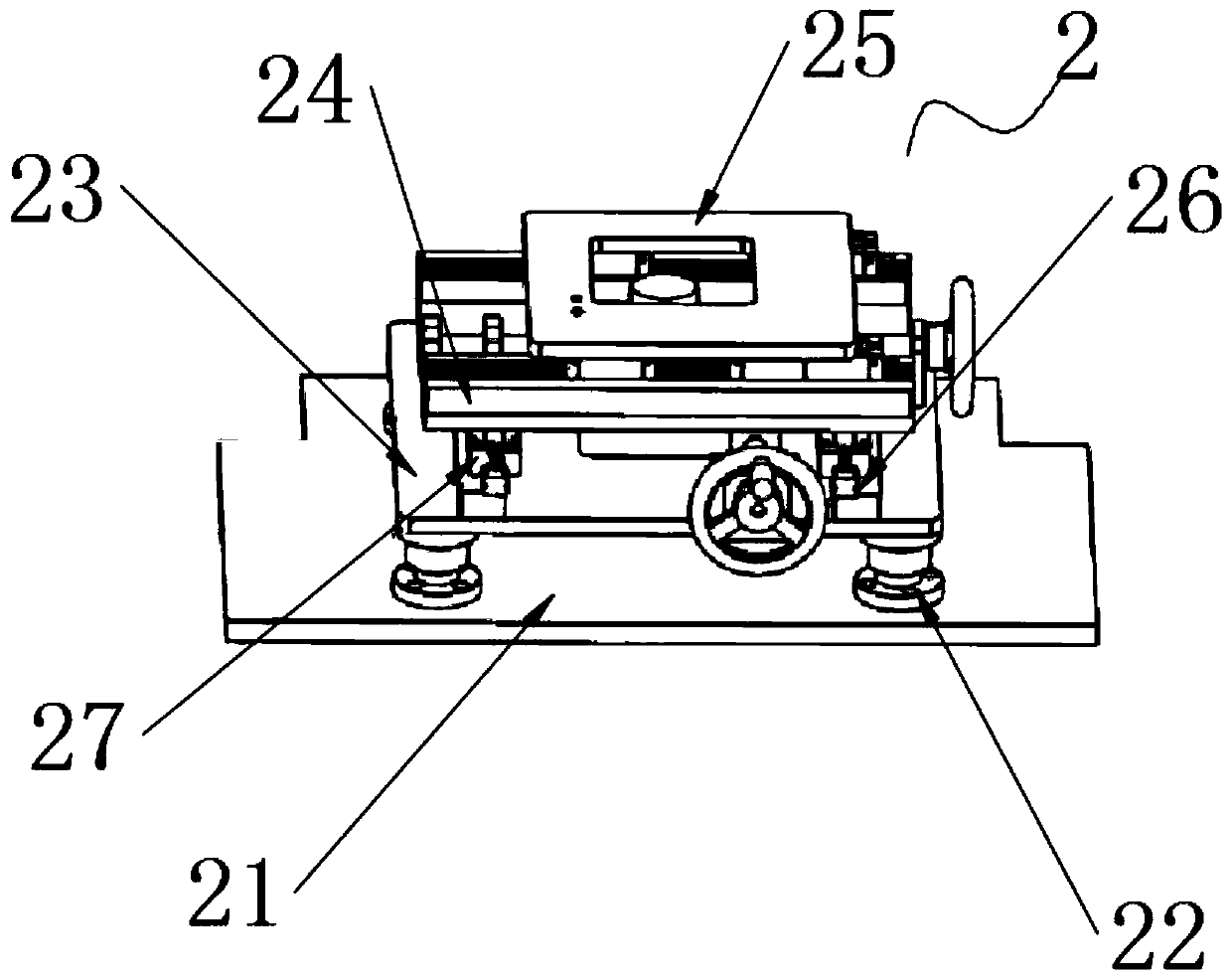

[0042] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a titanium nail riveting device assisted by a lateral ultrasonic energy field, including a frame 1 for support, wherein the frame 1 is composed of a column and an iron plate, and the iron plate adopts The A3 iron plate has good rigidity, and the force that the frame 1 bears is greater than 50KN, which improves the stability of the device. The top of the frame 1 is equipped with a fixture tooling module 2 for fixing objects, and one side of the fixture tooling module 2 is installed with a vertical installation frame 6, and the bottom end of the vertical mounting frame 6 is connected to the frame 1, the ultrasonic auxiliary module 3 is installed laterally on the vertical mounting frame 6, and the power module 4 is installed on the top of the vertical mounting frame 6, between the ultrasonic auxiliary module 3 and the power module 4 A data acquisition module 5 for collecting data is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com