Extruding method and mould for high-strength low carbon steel round head rivet

A technology of round head rivet and extrusion method, applied in the direction of metal extrusion die, etc., can solve problems such as low work efficiency, and achieve the effects of reducing labor intensity, improving material properties, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

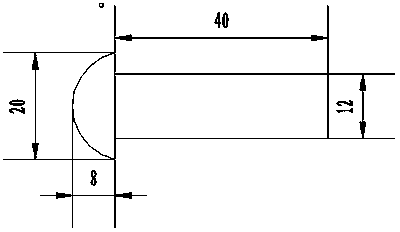

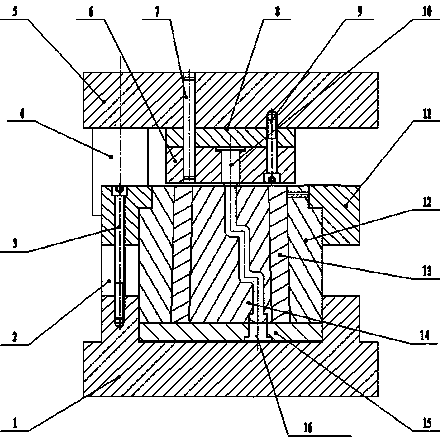

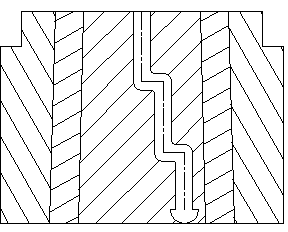

[0018] From figure 1 Shown mold assembly drawing of the present invention, figure 2 The prestressed combined die structure, image 3 The top view of the prestressed combined die and Figure 4 It can be seen from the design details of the extrusion channel in the left view of the prestressed combined die that the present invention mainly includes 1. Lower template 2. Guide pillar 3. Hexagon socket screw 4. Guide sleeve 5. Upper template 6. Punch fixed plate 7. Positioning cylindrical pin 8. Punch plate 9. Hexagon socket screw 10. Punch 11. Die plate 12. Second layer of die press sleeve 13. First layer of die press sleeve 14. Die 15. Block 16 . Die backing plate and other components. In the extrusion process, the materials used in the extrusion experiment are first cut by wire cutting, and then processed into a sample with a diameter of 12mm and a length of 40mm by cutting. For the angle extrusion die, due to the limited length of the punch, when the extruded part enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com