An anti-seepage geotextile for building surface gaps and its manufacturing method

A production method and technology of geotextiles, applied in construction, building components, building insulation materials, etc., can solve the problems that the anti-leakage method does not meet the needs of social development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

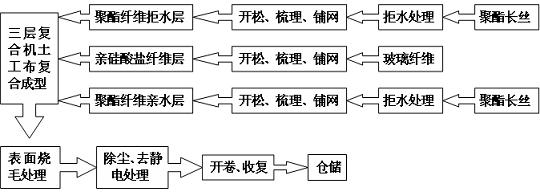

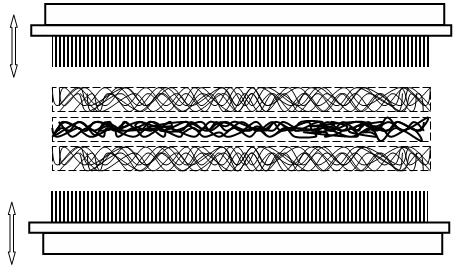

[0043] The present invention illustrates the specific implementation method as the best embodiment with the acupuncture composite manufacturing process:

[0044] image 3 It is a schematic diagram of the acupuncture composite process of the present invention; first, according to the design requirements, the materials of the three layers are respectively weighted according to the weight percentage, and the polyester filament is used as the upper and lower two-layer substrates, and the water-repellent and hydrophilic pre-treatments are respectively carried out. Processing: set the glass fiber as the middle layer base material, open the fiber layers of the three layers respectively, feed them to the carding machine for carding, and output them in parallel to the cross lapper, at a rate of 200g / m 2 Take geotextile as an example, the thickness of the net is about 5.0-6.0 cm, the net-guiding device is input to the acupuncture mechanism for reinforcement, the needle board is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com