Automatic winding and packaging mechanism of plastic pipe protective film

A plastic pipe and protective film technology, which is applied in the field of plastic pipe protective film automatic winding packaging mechanism, can solve the problems of reduced production speed, many processes, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

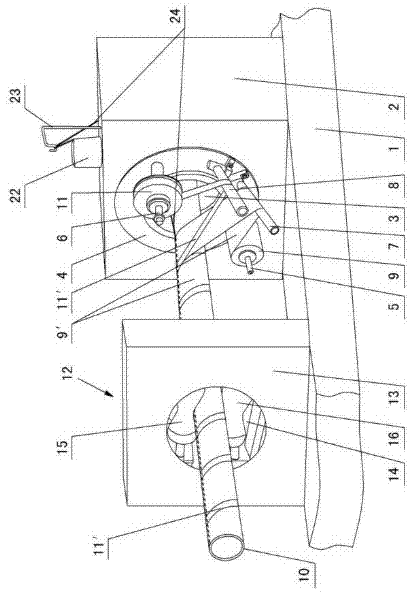

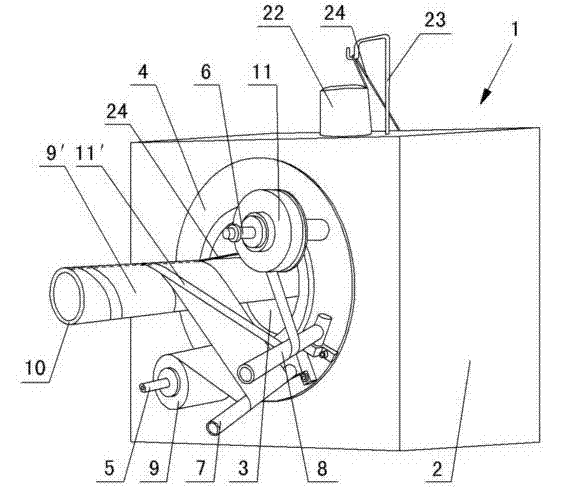

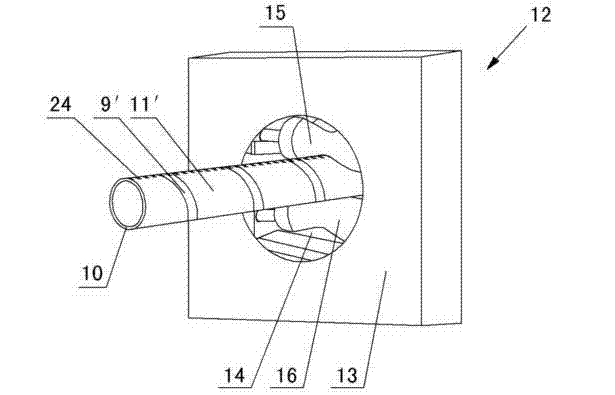

[0010] The invention relates to a plastic pipe protective film automatic winding packaging mechanism, such as Figure 1-Figure 3 As shown, it includes a conveyor base 1 connected to a plastic pipe manufacturing machine. Along the conveyor base, there are plastic pipes 10 produced by the manufacturing machine. It is characterized in that a plastic pipe protective film automatic winding packaging mechanism is installed on the conveyor base. , the plastic pipe protective film automatic wrapping packaging mechanism includes a packaging bracket 2 installed on the conveyor base 1, the center of the packaging bracket is shaped on a plastic pipe delivery hole 3, and a turntable 4 is installed on the front of the packaging bracket, and the turntable is driven by a power unit Rotate, fix the protective film fixing rod 5, the adhesive tape fixing rod 6, the protective film winding rod 7 and the tape winding rod 8 at the front end of the turntable, install the protective film roll 9 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com