Double sticky tape and punching method thereof

A technology of double-sided tape and adhesive layer, applied in the direction of adhesive, film/sheet adhesive, metal processing, etc., can solve the problems of time-consuming, affect the bonding effect, reduce the bonding area, etc. Paste time-saving, easy to tear off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that the words "inner" and "outer" used in the following description refer to directions toward or away from the geometric center of a specific component, respectively.

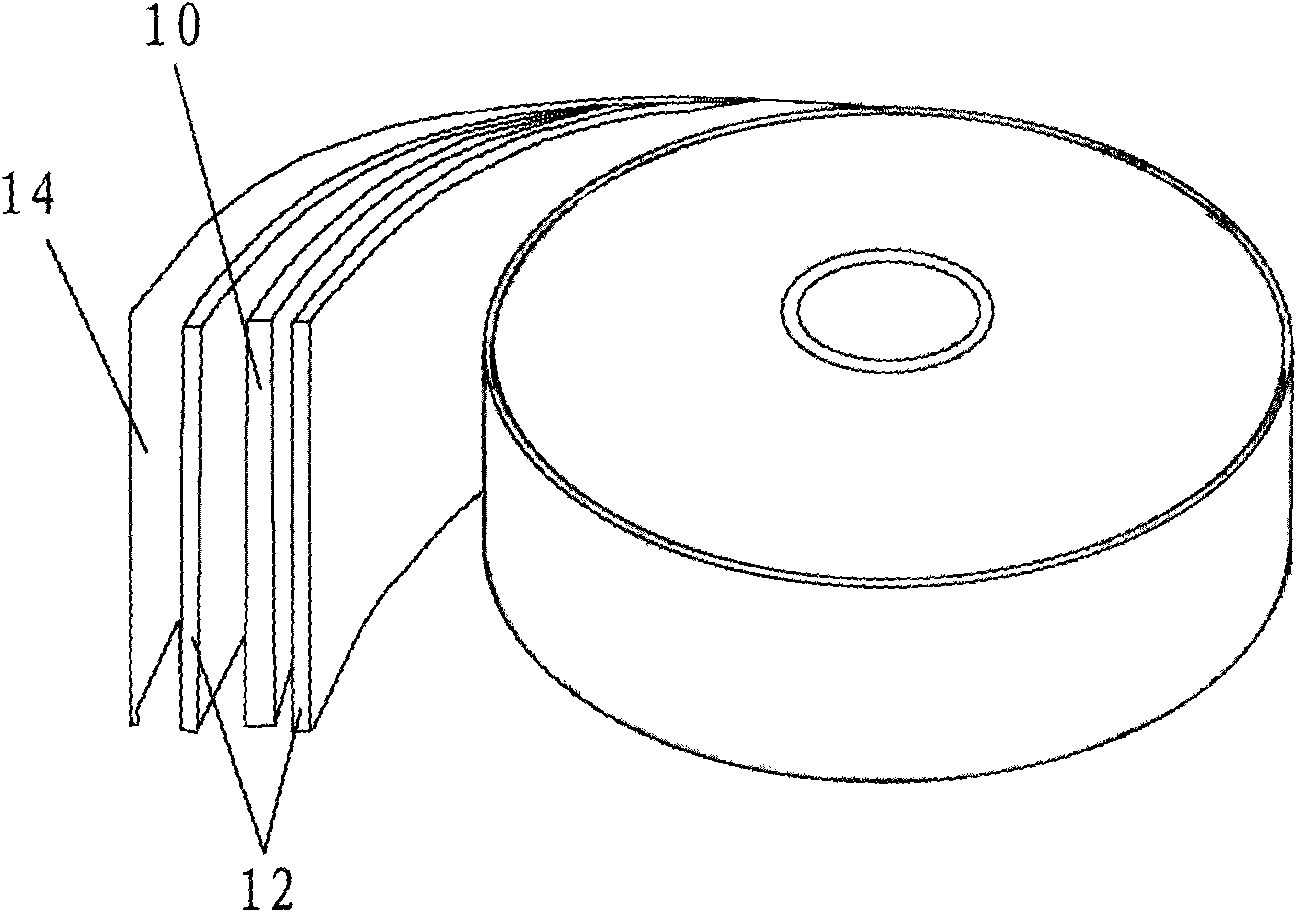

[0030] Such as image 3 As shown, the double-sided adhesive tape includes foam 10 , two adhesive layers 12 sandwiching the foam 10 , and release paper 14 stuck on the outer adhesive layers 12 . The double-sided adhesive tape is rolled before being attached to the parts, and the release paper 14 is used to separate the adhesive layers 12 of the rolled adhesive tape. After the double-sided adhesive tape is pasted on the parts, the release paper 14 still remains to protect the adhesive layer 12 on the other side, and the operator tears off the release paper 14 again during use.

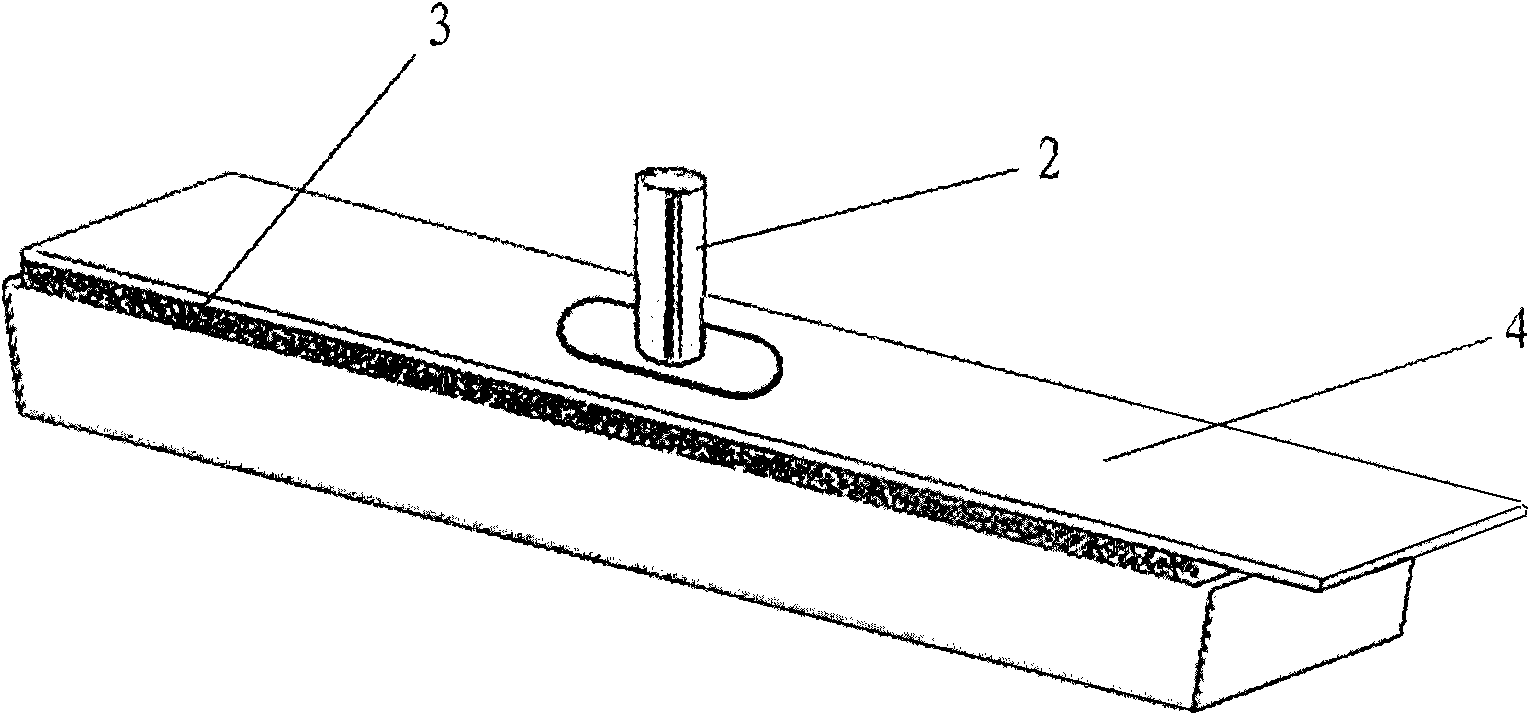

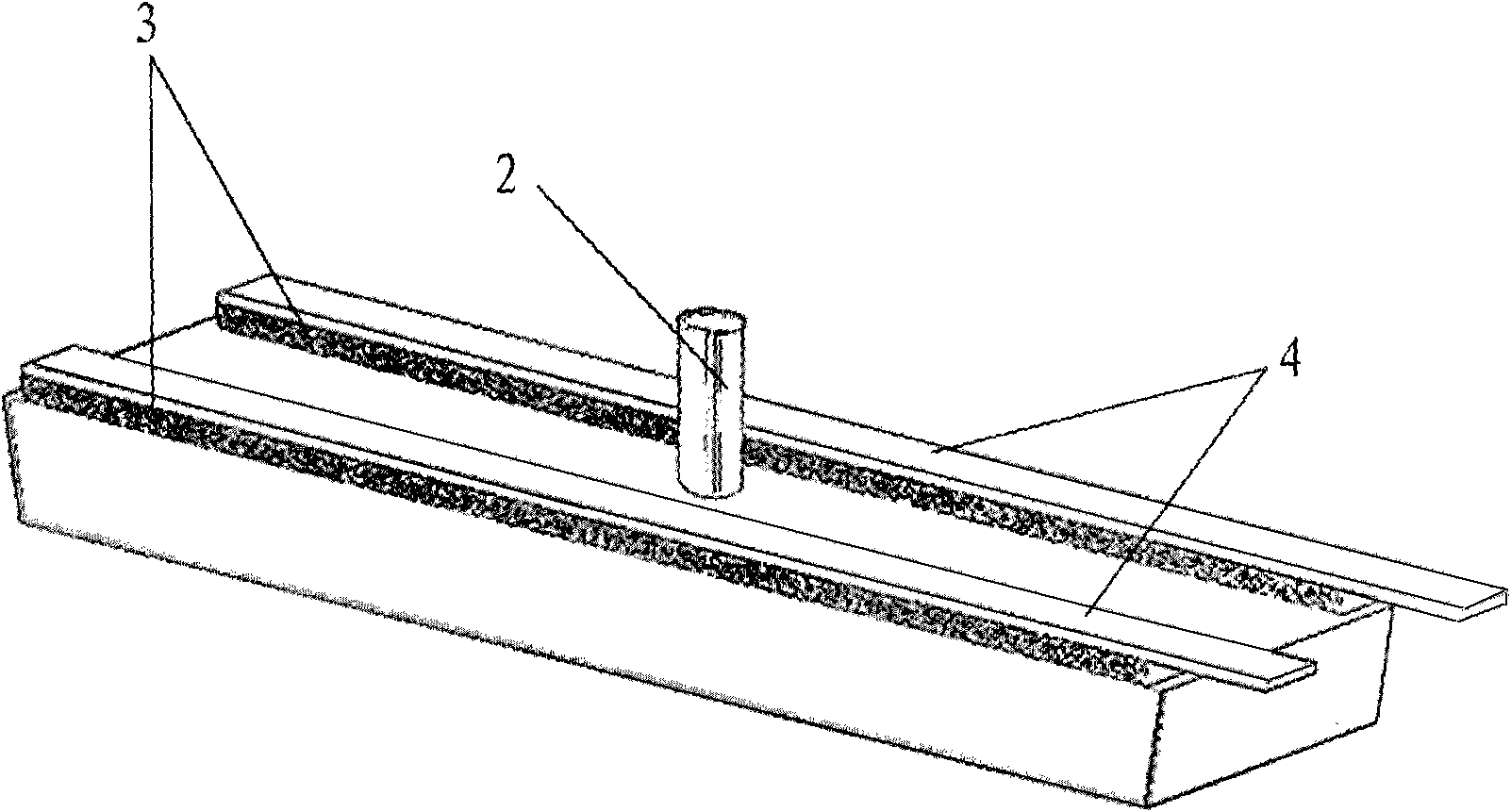

[0031] The punching method of the double-sided adhesive tape of the present invention is a punching method designed to smoothly avoid irregular structures or components on the adherend. Figure 5a , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com