Method for operating an anilox printing unit

A technology for printing devices and anilox rollers, applied to printing devices, general parts of printing machinery, printing, etc., can solve the problems of damaging the function of the blower device, polluting the blower device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

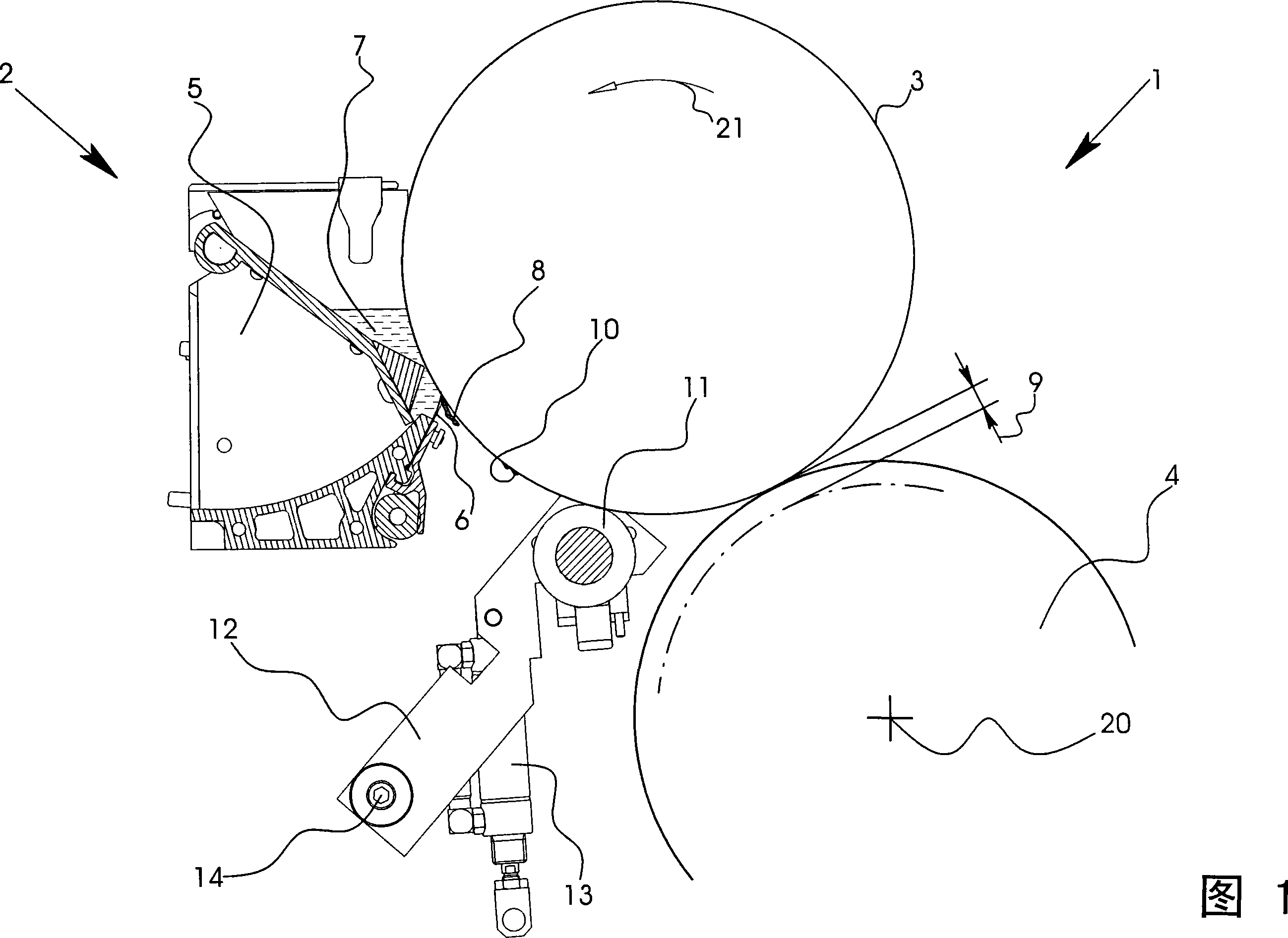

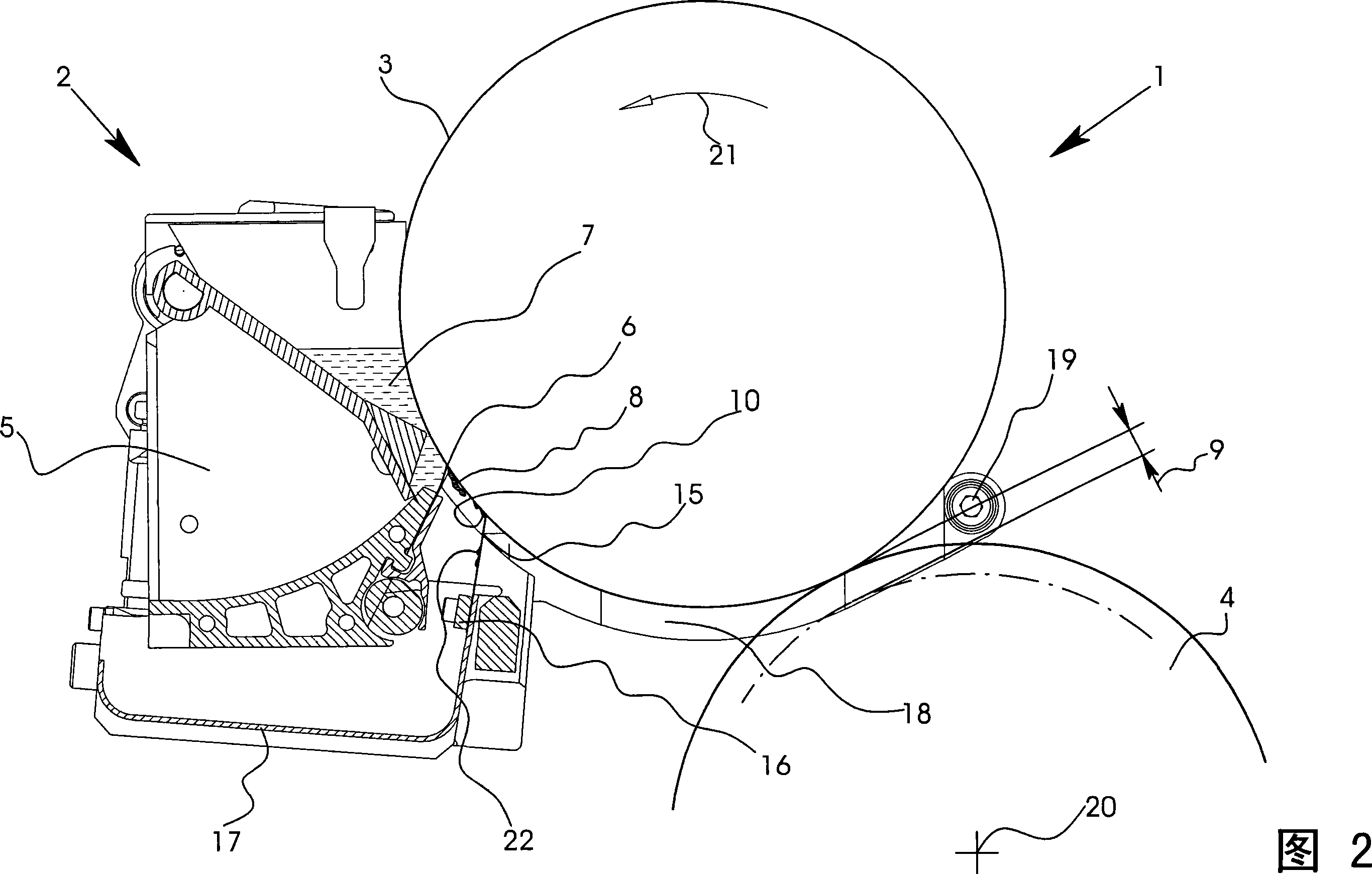

[0022] 1 and 2 each show a detail of a printing press 1 with an anilox printing unit 2 . The anilox printing unit 2 is an offset offset printing unit and comprises an anilox roll 3 and a further roll 4 onto which the anilox roll 3 transfers the printing ink. The other roller 4 is an ink form roller which rolls on a printing plate cylinder (not shown in the drawing) during the printing operation.

[0023] The screen roller 3 is equipped with an ink supply system in the form of an upwardly open doctor-type ink fountain 5 with a counter-working or supply doctor blade 6 . An ink supply 7 is located in the doctor-type ink fountain 5 . In the lower half of the screen roll 3 , the feed doctor blade 6 bears against the screen roll 3 in the region of its third quadrant.

[0024] Inevitably, over time, ink accumulates on the outside or underside of the feed doctor blade 6, which ink forms the so-called ink Must 8. When the screen roller 3 begins to rotate again at an increased speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com