DEVICE AND METHOD FOR MOIRe MEASUREMENT OF AN OPTICAL TEST SPECIMEN

A technology for optical testing and equipment, applied in the field of equipment and methods for Moiré measurement of optical testing samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

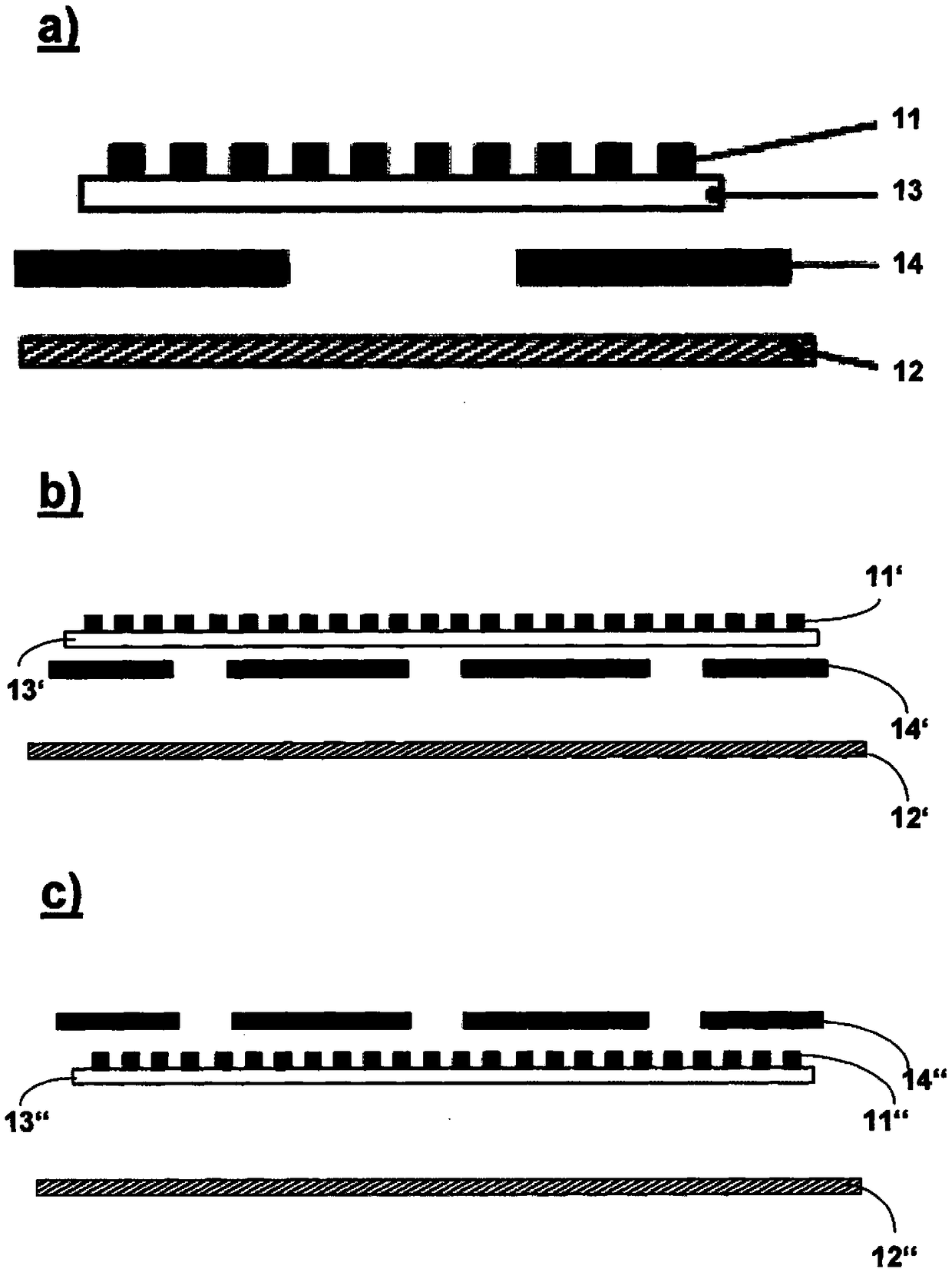

[0046] According to the present invention each figure 1 a-c provides aperture stop 14 (or figure 1 b and figure 1 c respectively 14' or 14"), the aperture stop 14 is laterally displaceable into different measuring positions along the direction of light propagation.

[0047] The resulting light distribution after the light emitted from the moiré mask or the second grating 11 can be shielded in a regionalized manner via the aperture stop 14, so that in each case only a subset of all field points reaches the detector 12 . The choice of measurable field points in the position of the aperture stop 14 can be such that light from different field points cannot be superimposed (where, for example, only every second, every third or every fourth field point). Capture of all field points on the moiré mask or on the second grating in a sequential measurement sequence can be achieved by displacing the aperture stop 14 into different measurement positions during successive measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com