Testing device for testing screw systems, and testing method for this purpose

A technology for inspection devices and spirals, applied in the direction of measuring devices, screwdrivers, instruments, etc., can solve the problems of cost realization, high complexity of measurement structure, high cost and consumption, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

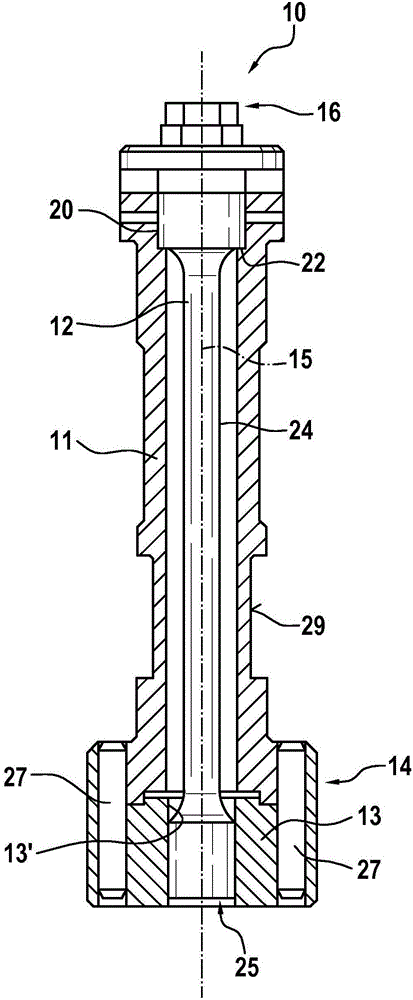

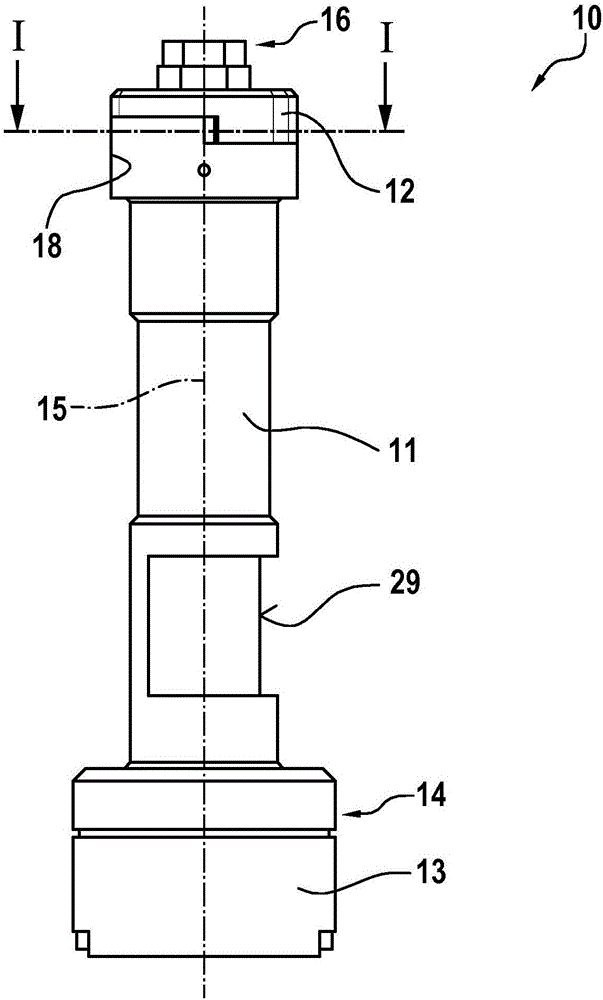

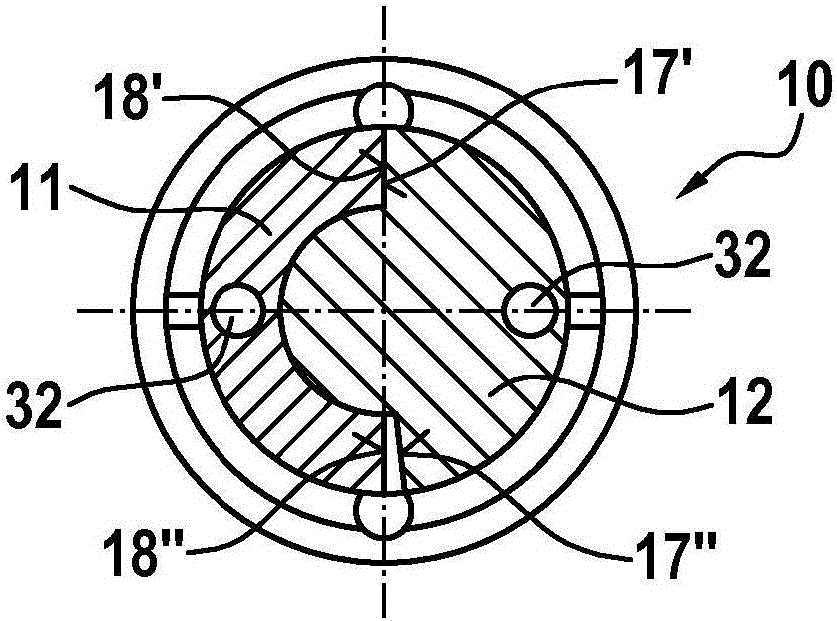

[0029] Figure 1 to Figure 5Shown is an inspection device 10 according to the invention, which is suitable for being connected to a threaded screw. The inspection device 10 has a base body 11 , a torsion body 12 received in the base body 11 and an adjustment disc 13 fixed at a lower end 14 of the base body 11 . The one-piece torsion body 12 is accommodated in the base body 11 coaxially to the longitudinal center axis 15 of the testing device 10 , wherein the hexagonally formed upper end 16 of the torsion body 12 protrudes upwards from the base body 11 and is positioned with For coupling or mating to screw leadscrews. Below the upper end 16 , the torsion body 12 has a shoulder 17 with a widened diameter, which has two abutment surfaces 17 ′ and 17 ″ spaced apart from one another in the circumferential direction, which are in contact with the base body. 11 has two stop surfaces 18' and 18" corresponding to it on its upper shoulder 18. The shoulder 17 of the torsion body 12 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com