Bearing electric corrosion wind driven generator structure defect detection mechanism and bearing electric corrosion wind driven generator structure defect detection method

A technology for wind power generators and structural defects, which is applied in the direction of motor generator testing, etc., to achieve the effect of easy operation and simple measurement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

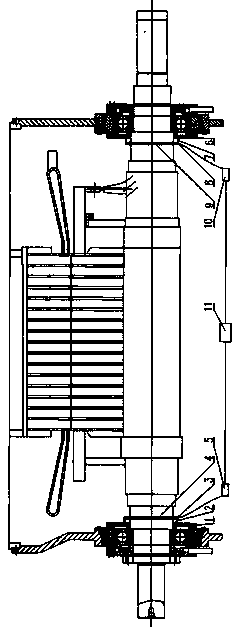

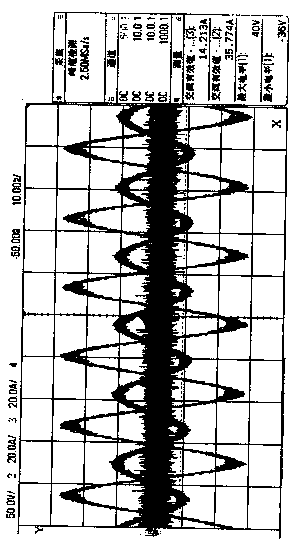

[0018] The present invention will be described in detail below in conjunction with the drawings:

[0019] A structure defect detection mechanism for a bearing galvanic wind generator, which includes the AS end bearing inner cover 1 of the bearing galvanic wind generator and the BS end bearing inner cover 6 of the bearing galvanic wind generator. The AS end bearing inner cover 1 The AS end insulation support frame 2 is provided on the inner surface, and the AS end Rogowski detection coil 4 is provided on the AS end insulation support frame 2. The AS end Rogowski detection coil 4 is wrapped around the shaft of the bearing galvanic wind generator. The Rogowski detection coil 4 on the AS side is bound and fixed with the insulation support frame 2 on the AS side by the AS side insulation binding band 3, and the Rogowski detection coil 4 on the AS side is electrically connected to the oscilloscope 11 through the AS side decoder 5.

[0020] A BS end insulation support frame 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com