Screw drives for stroke-controlled compensating adjustments

A technology of compensation adjustment and stroke control, applied in the direction of mechanical drive clutches, friction clutches, clutches, etc., can solve problems such as screw nut warping, compensation adjustment device obstruction, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

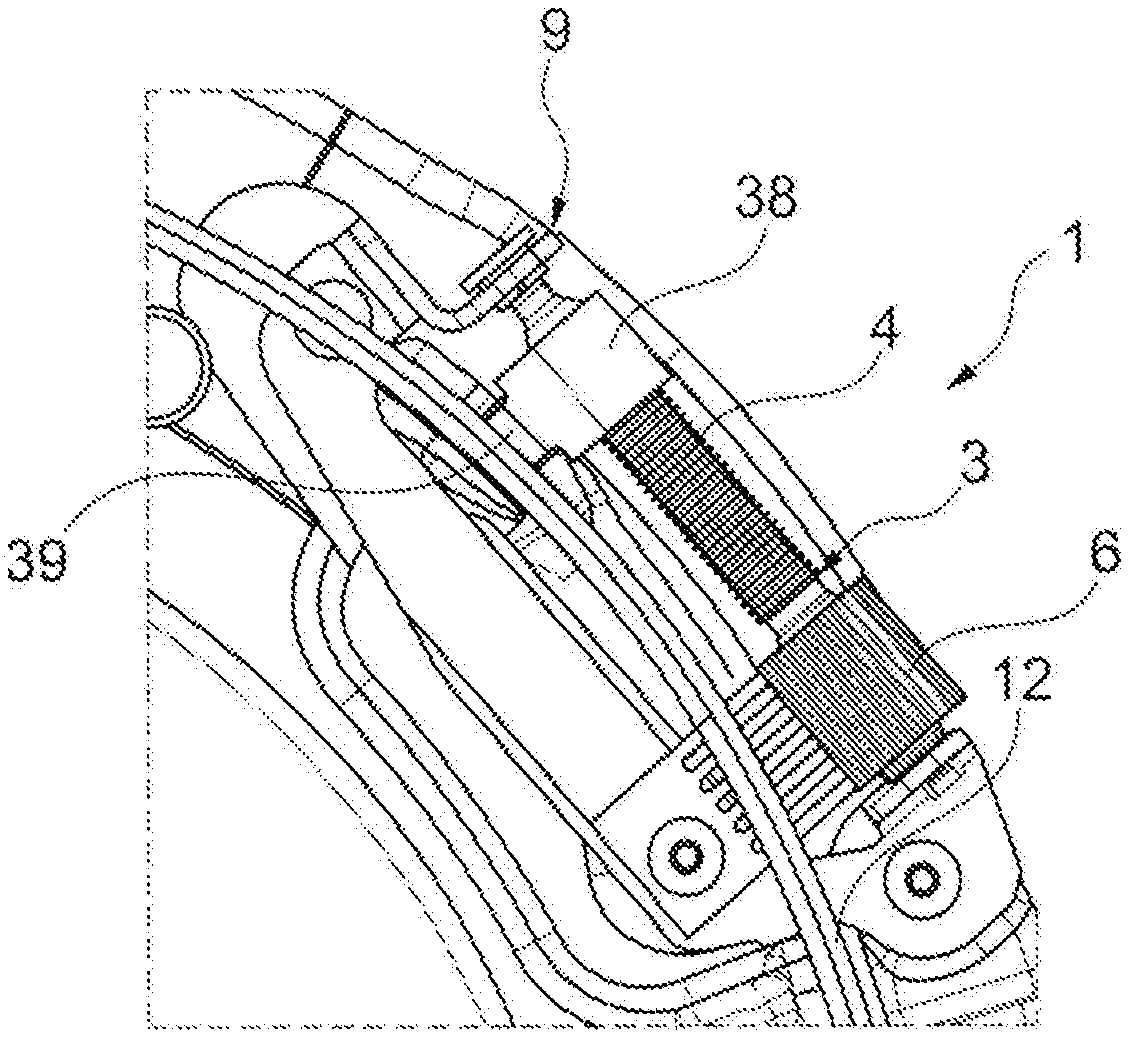

[0046] figure 1 A screw drive 1 is shown with a screw shaft 3 on which a worm drive 4 is arranged, which is driven by a drive pinion 6 . The spindle shaft 3 is received in the receptacle 9 and can thus be fastened to a component of the friction clutch. A conventional spindle nut 38 with a conventional transmission element 39 for compensating the adjusting ring 12 is arranged on the worm drive 4 . It is evident that, when the transfer element 39 is loaded, the spindle nut 38 can tilt and warp.

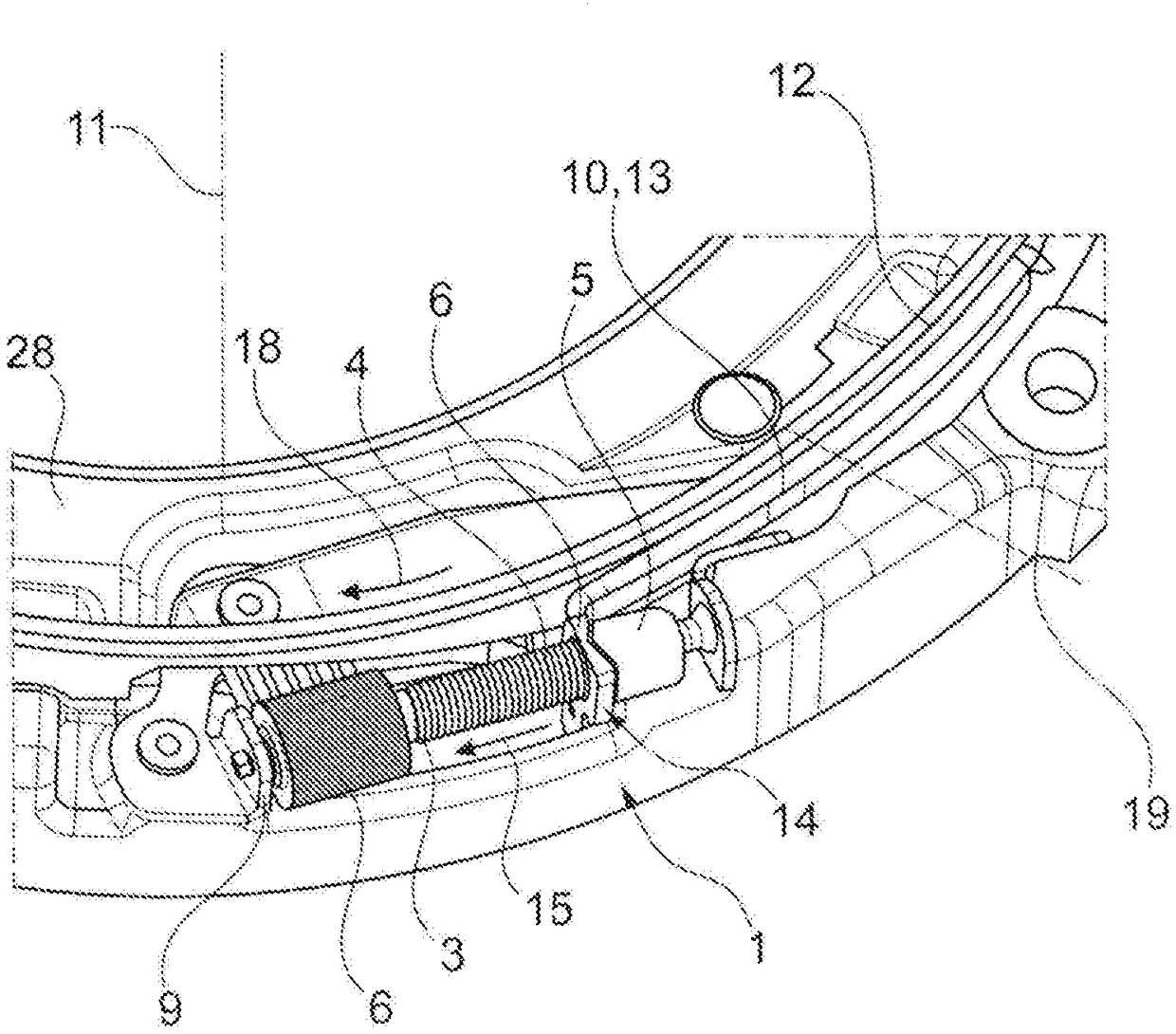

[0047] exist figure 2 The screw drive 1 in the receptacle 9 on the pressure plate 28 is shown in . Here, the screw shaft 3 with the worm drive 4 is twisted by driving the pinion 6 , so that the screw nut 5 is guided in the direction of movement 15 . The transmission element 10 , here embodied as a sheet-metal element 13 , is guided in the direction of movement 15 by the first flange 14 , so that the engaging compensating adjusting ring 12 in the compensating adjusting device 18 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com