Method and system for packaging rolls of products

a technology of product packaging and packaging rolls, applied in the direction of wrapping/bundling articles, packaging types, special packaging, etc., can solve the problems of affecting system productivity, requiring considerable implementation time for packaging, and being difficult to achiev

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

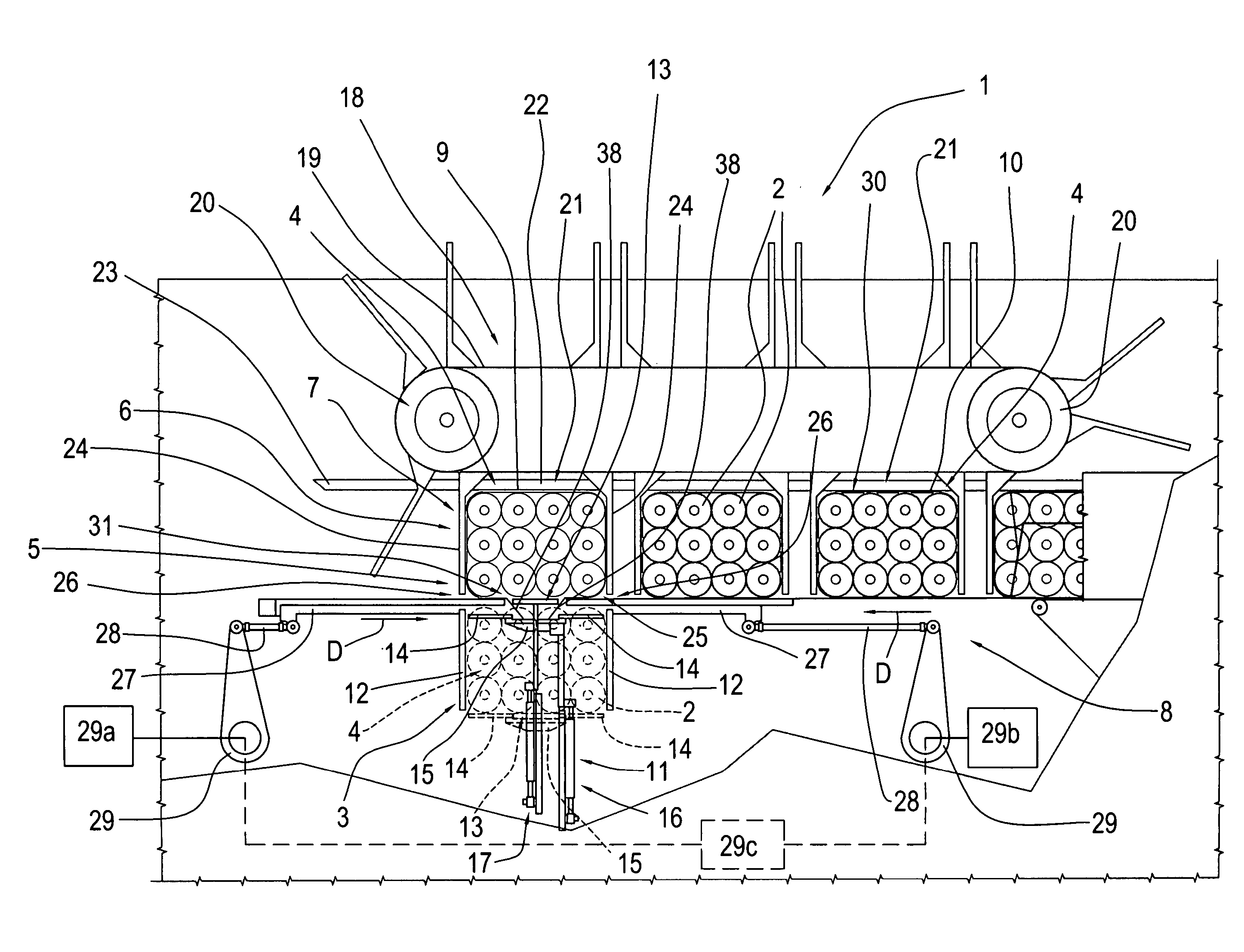

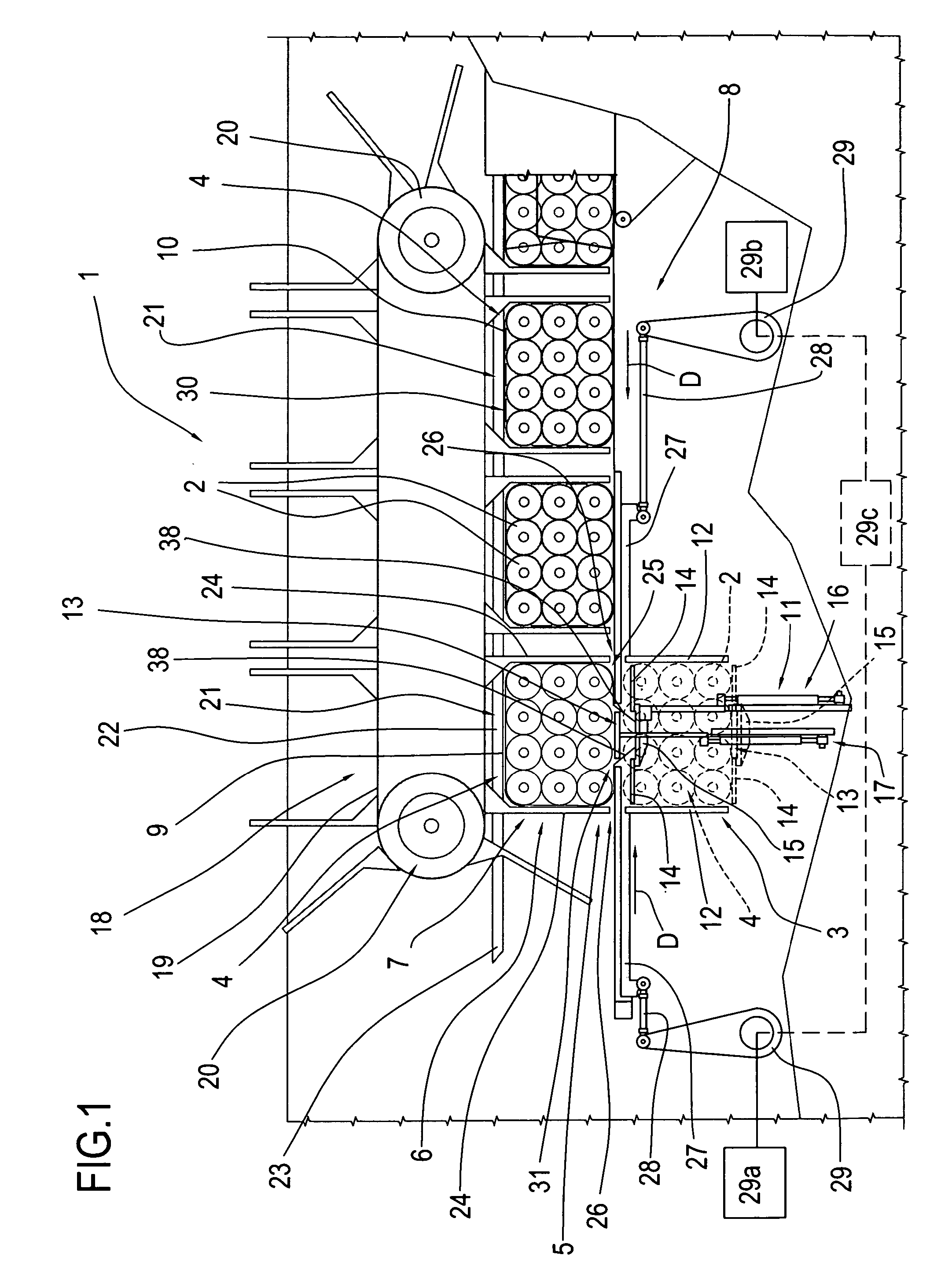

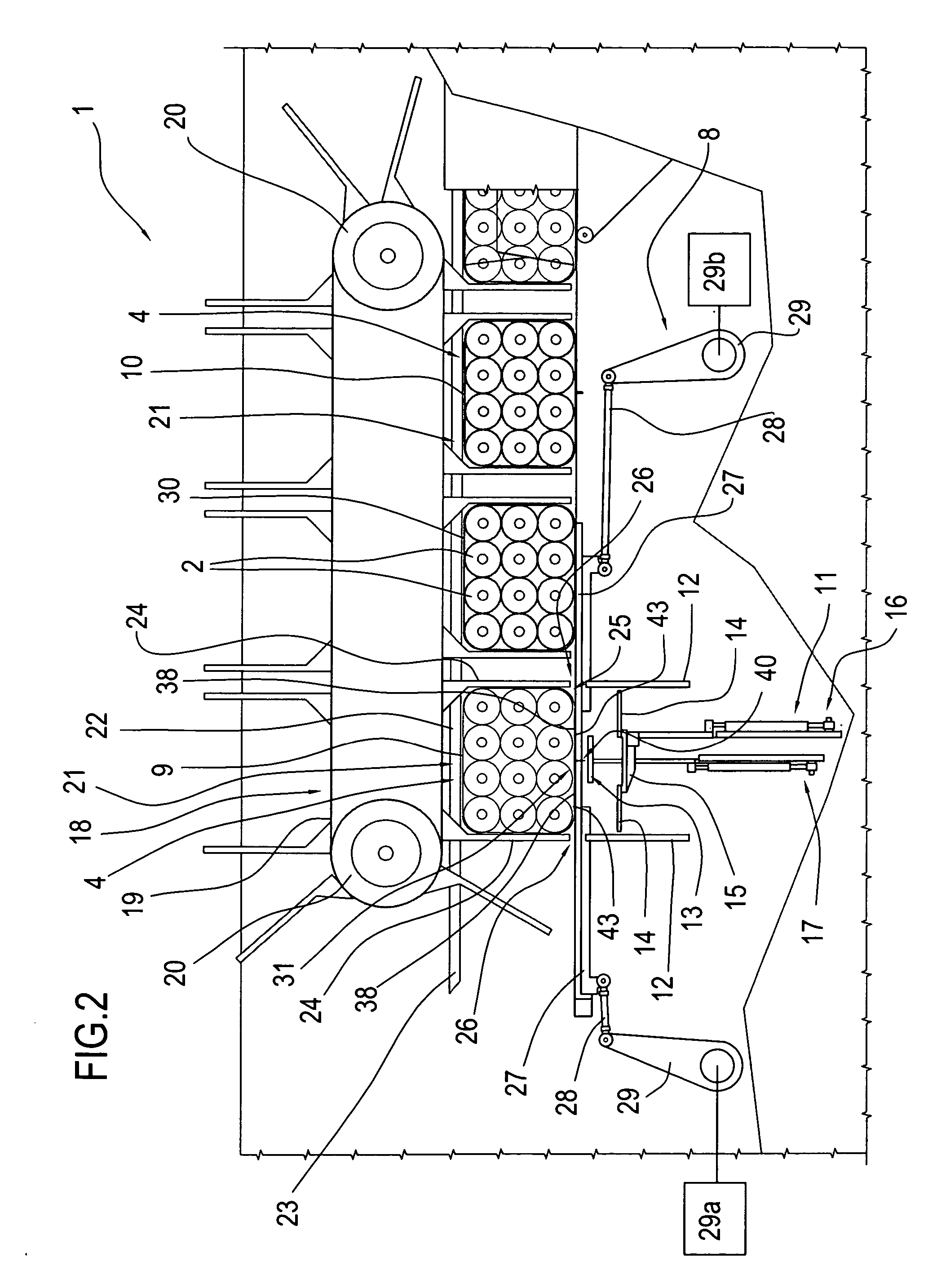

[0019] With reference to FIGS. 1 and 2, the numeral 1 denotes as a whole a system for packaging rolls of products, in particular rolls 2 of toilet and / or kitchen paper.

[0020] In the system 1, the rolls 2 are grouped, in the known way not illustrated, in one or more layers, each consisting of two or more rolls 2 lined up in a row or in rows and columns, and the rolls are sent to a feed station 3. In particular, in the embodiment illustrated, without limiting the scope of the invention, the rolls 2 are arranged in parallelepiped groups 4 in three layers 5, 6 and 7.

[0021] Downstream of the feed station 3, the system 1 comprises a packaging unit 8, designed to wrap each group 4 with a wrapping sheet 9 and to stabilize the wrapper 10 obtained in this way.

[0022] The wrapping sheet 9 is made of a heat-sealable material, preferably transparent polypropylene.

[0023] The feed station 3 and the packaging unit 8 are arranged one after the other, the former below the latter, with transfer mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com